Chapter 6 Transducers

INTRODUCTION

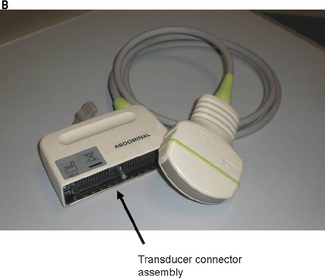

The transducer is one of the most critical components of any diagnostic ultrasound system. There are many types of ultrasound transducers that can be selected before performing an ultrasound investigation as seen in Figure 6.1, and a great deal of attention should be paid to selecting the most appropriate transducer for the application.

Ultrasound transducers are described by their type and operating frequency which can range from 2 MHz up to 20 MHz and are selected based on their ‘fitness for purpose’. The end user must recognize that different applications require an appropriately selected transducer which is best suited for a particular investigation.

We need to be aware that there is a trade-off between image resolution and the penetrating depth of ultrasound which is governed by its frequency. For example, a 12 MHz transducer has very good resolution, but cannot penetrate very deep into the body compared to a 3 MHz transducer which can penetrate deep into the body, but the resolution is not as good as the transducer operating at 12 MHz. In general use, the highest frequency transducer which will reach the required depth should always be employed.

THE TRANSDUCER

Diagnostic transducers act as both a transmitter and receiver of ultrasound and are able to produce beams which can be directed in various ways to improve the quality of the images that we see on screen.

The primary component of the transducer is made from a piezoelectric material which means they are able to convert one form of energy to another, in this case electrical energy into mechanical energy and vice versa.

Components and Construction of a Typical Transducer

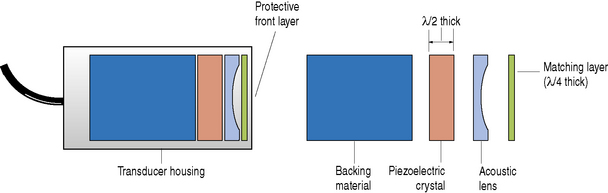

There are many types of transducers ranging from a simple single element to electronic multi-array probes which have hundreds of elements. The components and construction of these different types of transducers are principally the same. To understand how modern day electronic multi-element transducers function we need to start by considering the construction and components of a simple single element circular transducer. This is illustrated in Figure 6.2.

The main components of a typical ultrasound transducer consist of:

Physical housing

This contains all the individual components including the crystal, electrodes, matching layer, and backing material. This housing provides the necessary structural support and acts as an electrical and acoustic insulator.

Electrical connections

Two electrical connections are formed on the front and back face of the crystal by plating a thin film of gold or silver on these surfaces. These electrodes are connected to the ultrasound machine which generates the short burst of electrical pulses to excite the crystal and through the piezoelectric effect generates a pulse of ultrasound energy.

Piezoelectric element

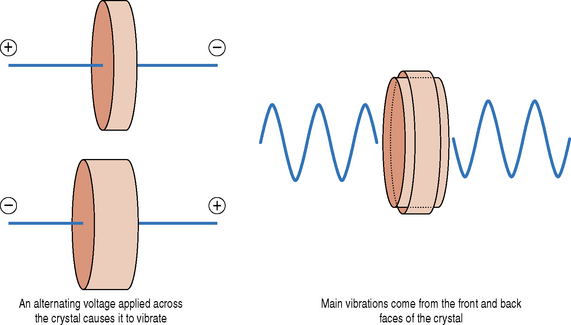

Transducers operate on the piezoelectric effect which was discovered by Jacques and Pierre Curie in 1880. They found that certain crystalline minerals when subjected to a mechanical force became electrically polarized which means that they generated voltages. They also discovered that the converse was true, i.e. if a short electrical burst was applied to these crystals it would cause them to vibrate. The term ‘piezoelectric’ was derived from the Greek word ‘piezein’, meaning to press or squeeze.

By utilizing this piezoelectric property an ultrasound transducer can act both as a transmitter and receiver of ultrasound.

In transmission mode, a short burst of electric energy generated by the ultrasound scanner (typically one to three cycles of alternating voltage for imaging) is sent to the transducer generating an ultrasound pulse of energy. Reflected ultrasound echoes returning to the transducer face are detected, causing mechanical vibrations which are converted into electrical voltages. It is these electrical signals that are processed by the ultrasound machine which form the images that we see.

What are they made of?

Quartz is a naturally occurring material with piezoelectric properties and was extensively used in the development of early machines. This has now been superseded by man-made ceramics such as lead zirconate titanate (PZT) which are more efficient, have better sensitivity, and can easily be shaped.

How do you determine a transducer’s operating frequency?

The operating frequency of a transducer is critically governed by the thickness of the piezoelectric crystal. For maximum efficiency the crystal should be operating at its ‘natural’ or ‘resonant’ frequency. This occurs when the thickness of the crystal corresponds to half a wavelength (λ/2).

We have already discovered that wavelength and frequency are inversely related, i.e. as wavelength decreases frequency increases, therefore we can appreciate that thinner piezoelectric materials produce higher resonant frequencies. Typical diagnostic ultrasound elements are between 0.2 mm and 1 mm thick.

A transducer operating at a resonant frequency of 2 MHz would have a thickness around 1 mm. In comparison, a transducer operating at a much higher frequency, say 7.5 MHz, would have a typical thickness of 0.3 mm.

Purpose of the backing material

Let us consider a simple single element transducer as illustrated in Figure 6.3. When a short burst or pulse of electricity is applied to a crystal it causes it to vibrate in all directions. The main vibrations come from the front and back faces of the piezoelectric crystal. We are only interested in the vibrations that come off the front face of the transducer. To try and eliminate the vibrations from the back face, and to control the length of vibrations from the front face, a backing or damping material is used. This damping material, which typically consists of tungsten powder and plastic or epoxy resin, is attached to the back face of the piezoelectric crystal.

Fig. 6.3 When a short pulse of electricity is applied across the crystal it causes it to vibrate. The main vibrations are generated from the front and back face of the crystal

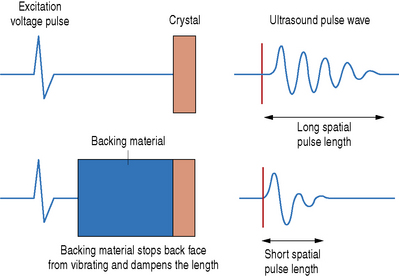

Figure 6.4 shows that without the backing material a longer pulse of ultrasound is generated by a short burst of electricity as the crystal continues to vibrate or rings. These vibrations naturally fade out with time. An example of this effect can be heard when a cymbal is hit by a drumstick and continues to ring for some time. Attaching a backing material on the rear face of the element dampens the vibrations and generates a shorter ultrasound pulse. The length of the ultrasound pulse is known as the spatial pulse length (SPL).

Fig. 6.4 The effect of a backing material is to eliminate any vibrations from the back face of the crystal and to produce a short pulse of ultrasound

Ultrasound pulses which are used for imaging are typically two to three cycles long. The advantage of having a short ultrasound pulse for diagnostic imaging is that it improves the resolution of the ultrasound images and in particular improves the axial resolution.

However, the damping material makes the generation of ultrasound less efficient and also reduces the sensitivity of the transducer to detect weak echoes. This is the price to pay for improved resolution.

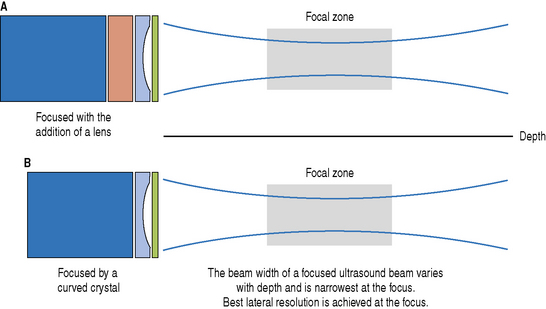

Acoustic lens

The purpose of the acoustic lens is to improve image resolution by reducing the beam width of the transducer. The width of the beam determines the lateral resolution. The lateral resolution is the ability to resolve structures across or perpendicular to the beam axis. For a single element transducer sound may be focused by the addition of a lens (Fig. 6.5a) or by using a curved piezoelectric crystal (Fig. 6.5b). The lateral resolution of an ultrasound beam varies with depth and is best at the focal region where the beam is narrowest.

Impedance matching layers

An acoustic impedance matching layer is sandwiched between the piezoelectric crystal and the patient and is an important factor that affects the sensitivity of the transducer, i.e. the ability of the ultrasound system to detect small reflected echoes. A large difference in acoustic impedance (Z) between two objects results in a large reflection of the incident ultrasound beam. The difference in acoustic impedance between the crystal and soft tissues within the patient is large (>15 times), and without this matching layer, most of the acoustic energy (typically 80%) would be reflected at this boundary with only around 20% being transmitted into the patient.

The matching layer typically has an acoustic impedance value halfway between that of the crystal and soft tissue. This results in more transmitted energy entering the patient and improves the signal strength of any returning echoes, which in turn improves the ultrasound system’s sensitivity and image resolution.

More than one matching layer can be used and they are typically constructed to be one quarter wavelength thick (λ/4).

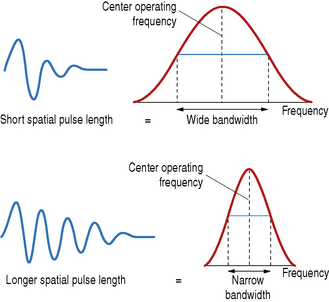

Relationship between Spatial Pulse Length and Bandwidth

We have discussed how transducers operate at their resonant frequency which is governed by the thickness of the piezoelectric crystal. However, the short pulses of ultrasound that are produced by damping the pulse in fact contain a range of frequencies which are centered around this operating frequency. The range of frequencies contained within an ultrasound pulse is referred to as its bandwidth. One of the factors that affect the bandwidth of a transducer is the spatial pulse length. Pulses which have short spatial pulse lengths contain a wider range of frequencies, i.e. have a wide bandwidth. On the other hand, ultrasound pulses which have longer spatial pulse lengths contain a narrower range of frequencies, i.e. have a narrow bandwidth. This is illustrated in Figure 6.6.

Fig. 6.6 Demonstrating the relationship between spatial pulse length and bandwidth. The shorter ultrasound pulse contains a wider spread of frequencies known as the bandwidth. In comparison, a pulse which has a longer pulse duration, i.e. longer spatial pulse length, has a narrower bandwidth

The wideband characteristics of modern day ultrasound transducers results in the end user being able to simply push a button to switch to a higher or lower operating frequency rather than changing the transducer. This enables the operator to choose a higher frequency to provide better detail resolution (resulting in some loss to the penetrating depth of the ultrasound beam) and switching to a lower frequency to increase the penetration of the ultrasound beam (resulting in some loss to image quality).

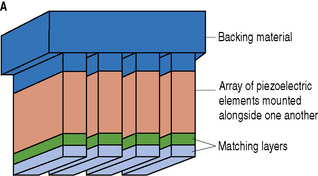

ELECTRONIC MULTI-ARRAY TRANSDUCERS

Electronic transducers have an array of rectangular shaped piezoelectric crystals etched side by side into one PZT ceramic (see Fig. 6.7a) which is mounted within the transducer housing. The internal components are similar to the simple single element transducer that was described earlier, in that they both have a backing material attached to the back face of the piezoelectric element to shorten the pulse length, and matching layers attached to the front face to improve the sound transmission into the patient.

Fig. 6.7 a) Internal construction components of an electronic array transducer. b) Picture of the hundreds of connections at the transducer connector assembly

Typically, there are between 128–256 elements across the face of these transducers which are individually connected through one of the ultrasound machine ports. Figure 6.7b shows the hundreds of connections at the end of a transducer connector assembly.

Being able to control the firing sequence of each of the individual elements across the face of a transducer enables the operator, through the machine’s front end controls, to manipulate the shape and direction of the ultrasound beam.

FORMING ULTRASOUND IMAGES

Ultrasound images are not created by firing all the elements in an electronic array transducer at the same time. They are formed by transmitting a series of small narrow beams along the transducer face which are directed along adjacent paths through the patient to generate one cross-sectional image.

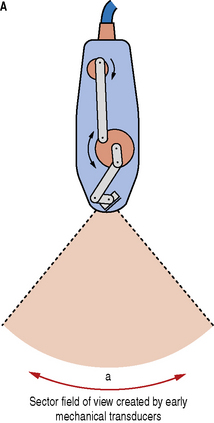

Historically, early transducers were built to have one crystal which was moved mechanically by a small motor to sweep the beam over an area of the patient. An example of this early type of mechanical transducer is illustrated in Figure 6.8a which produces what is known as a sector field of view.

Fig. 6.8 a) An example of an early mechanical transducer based on a single element which is mechanically swept over a range of angles to produce a sector field of view. b) A picture of a selection of modern day multi-element electronic transducers

Although these mechanical transducers can still be found, they were superseded by the modern electronic transducers that we use today (Fig. 6.8b).

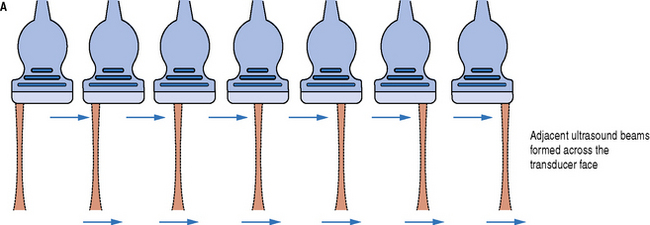

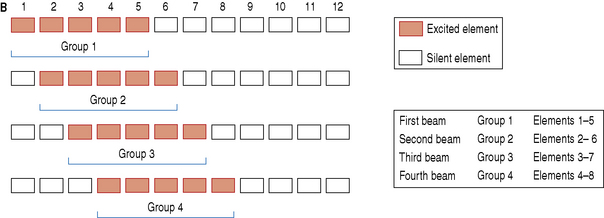

Electronic transducers form an image by using small groups of elements (typically 5–10) to produce a narrow ultrasound beam which forms a scan line. The ultrasound machine can very rapidly sequentially sweep the position of this beam across the face of the transducer to produce a cross-sectional image as seen in Figure 6.9a. The firing sequencing of the groups of elements across a linear array transducer is illustrated in Figure 6.9b.

Fig. 6.9 a) Ultrasound beam scanning is performed electronically by sequentially activating small groups of elements across the face of the transducer. b) Demonstrating the firing sequence for a group of elements across a transducer face

The first group of elements, in this case 1–5, are selected to create the first beam to form a scan line. Once all the returning echoes are received then a second group of elements are fired to form an adjacent scan line, again waiting for all the returning echoes to be received before moving onto the next group and so on. In this case this results in a rectangular image being produced for a linear array transducer.

ELECTRONIC BEAM FOCUSING AND STEERING

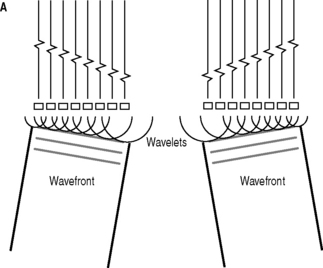

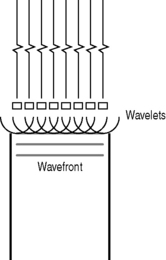

The ultrasound beam generated from electronic array transducers are formed by using groups of elements. These individual elements create small wavelets that interact with each other to form an overall ultrasound beam with a characteristic wavefront.

Consider a group of elements which are all excited simultaneously (seen in Fig. 6.10). The individual elements create small wavelets which interact together to form an ultrasound beam which has a wavefront that travels perpendicular to the face of the transducer.

Fig. 6.10 A group of elements are excited simultaneously, generating an ultrasound beam with a wavefront which travels perpendicular to the face of the transducer

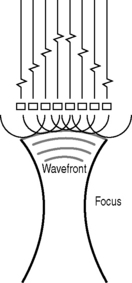

By introducing a set of time delays to the individual elements, the ultrasound beam’s shape and direction can be electronically manipulated to focus and steer the ultrasound beam.

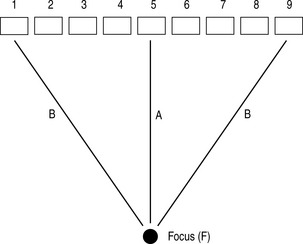

Electronic Beam Focusing

We have already discussed that focusing the ultrasound beam improves the image quality (resolution) by making the beam thinner within the focal zone. A simple single element transducer focuses the beam by either utilizing an acoustic lens or by using a curved piezoelectric crystal. Electronic transducers focus the beam by introducing a series of time delays across a group of elements which are to be excited. Consider a group of nine elements which require a beam to be focused at a depth A (Fig. 6.11).

To create a beam which is focused at depth A requires all the wavelets created by each individual element to converge, i.e. to arrive at the desired focal point at the same time. We can see that the distance between the focus and the individual elements vary. The shortest distance is path A, between the focus and the center element. The longest distance, path B, involves the outermost elements (1 and 9). So to ensure that all the wavelets arrive at the same point at the same time, the ultrasound machine through the beam former introduces a set of time delays across the individual elements. As the outermost elements (1 and 9) have the furthest to travel they are excited first, followed by elements 2 and 8, then 3 and 7 and so on. The last element to be excited will be element 5. Figure 6.12 shows a typical sequence of time delays to produce an electronically focused beam.

Fig. 6.12 A typical sequence of time delays introduced across a group of elements to produce a focused ultrasound beam

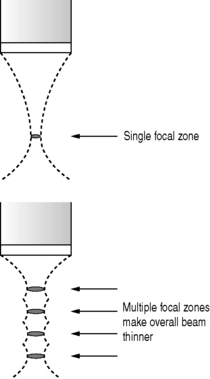

Because focusing is achieved by introducing a set of electronic time delays, the position of the focal zone can be controlled by changing the timing sequence of these delays. Greater time delays create beams which are focused near to the transducer face. Longer time delays move the focal position further away from the transducer and deeper into the patient.

Operators are able to choose more than one focus and create beams with multiple focal zones which effectively creates a long narrow beam as illustrated in Figure 6.13. The advantage of using multiple focal zones is that overall image quality is improved throughout the image. The main disadvantage is that for each additional focal zone another pulse has to be sent out along the same scan line. The more focal zones selected the more time it takes to form a scan line which results in the frame rate being reduced, making the images appear disjointed.

Electronic Beam Steering

The ultrasound beam can also be steered by introducing a set sequence of time delays to the transmit pulses across a group of individual elements. The angle at which the beam is produced will depend on the delay between the excitation pulses of the individual elements. A typical sequence of time delays is demonstrated in Figure 6.14a. An image is formed by electronically sweeping the direction of the ultrasound beam across the transducer face by changing the delay between every set of excitation pulses so that the ultrasound beam is steered over a wide range of angles to form a wide ‘sector’ field of view (Fig. 6.14b).

TYPES OF ELECTRONIC ARRAY TRANSDUCERS

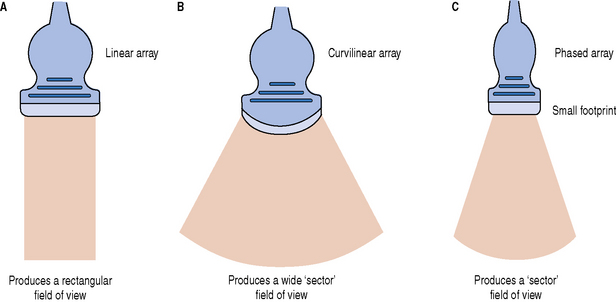

All the different types of transducers currently available can be characterized into three main types and are illustrated in Figure 6.15. They consist of:

Fig. 6.15 Three types of electronic array transducers. a) Linear array; b) curvilinear array; c) phased array

Linear Array Transducers

This type of array is typically made of between 128–256 elements in a row and produces parallel scan lines which are transmitted perpendicularly to the transducer face resulting in a rectangular field of view (see Fig. 6.15a). The width of this image is approximately equal to the length of the transducer head. Linear array transducers are used to image superficial structures and vessels and therefore operate at frequencies typically above 4 MHz. They are extensively used for vascular, small parts and musculoskeletal applications.

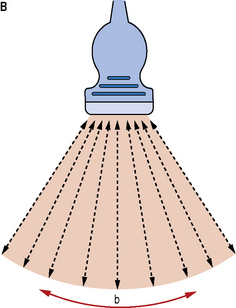

Curvilinear Array Transducers

This type of transducer is similar to a linear array but the transducer face is formed into a curve (convex in shape) which provides a wide field of view which diverges with depth (see Fig. 6.15b). These transducers are sometimes referred to as sector arrays. Curvilinear transducers operate at lower frequencies compared to linear arrays, typically around 3.5 MHz, and are best suited to image deep-lying structures. Their main applications are in abdominal and obstetric scanning.

Phased Array Transducers

Phased array transducers are similar to a linear array, being a flat-faced transducer with a row of elements positioned alongside one another. The crucial difference between the phased array and linear and curvilinear transducers is that the beam is electronically steered to produce an image. As a consequence of this, phased array transducers have a wide field of view similar to that of curvilinear transducers (see Fig. 6.15c).

These transducers are physically smaller than their counterparts and provide a wide field of view from a small transducer contact area, known as a footprint. The small footprint and wide field of view of these transducers are typically utilized in cardiac applications where it is difficult to image the heart because of the ribcage. These small transducers can easily fit between the ribs or underneath the ribcage to obtain an image of the heart. Typically operating at frequencies similar to curvilinear transducers, they are used to image deep-lying structures and perform specialized transcranial investigations.