Anesthesia Ventilators

PHYSIOLOGY AND MECHANICAL CONCEPTS

LUNG FUNCTION DURING ANESTHESIA AND MECHANICAL VENTILATION

CLASSIFICATION, SPECIAL FEATURES, AND MODES OF VENTILATION

CAPABILITIES AND LIMITATIONS OF ANESTHESIA VENTILATORS

Anesthesia Versus Critical Care Ventilators

System Compliance and Compression of Gas

CURRENT DESIGNS OF ANESTHESIA VENTILATORS

Overview

Since the 1960s, the use of intermittent positive-pressure ventilation (IPPV) has become widespread. Today’s observer might wrongly conclude that the research, development, and methods for mechanical ventilation in the operating room (OR) had occurred only recently. However, much of the necessary experimentation and design took place much earlier.

Anesthesia ventilators are commonly compared with mechanical ventilators used in the intensive care unit (ICU); however, anesthesia ventilators are unique; they not only deliver oxygen and remove carbon dioxide, they also facilitate the delivery of inhalational agents used to render patients unconscious and maintain surgical anesthesia. Modern delivery systems typically are semiclosed systems, which require removal of carbon dioxide and conservation of potent inhalational agents. Low gas flows are commonly used to aid in agent sparing and reduce patient exposure to unheated gases. In contrast, the ICU ventilator typically has an open system because no gases are recirculated through the system; as such, a carbon dioxide absorber is not used. High gas flows can be used because elaborate gas-warming and humidification techniques are available and have proven cost effective in the ICU.

In the past, it was not uncommon to bring an ICU ventilator into the OR for oxygenation and ventilation of patients with extremes of pulmonary pathophysiology because these machines had more options. Recent advances in ventilator technology have made the differences between ICU ventilators and anesthesia ventilators negligible. Outcome data continue to be lacking in the scientific literature regarding differences in modes used in the OR: synchronized intermittent mechanical ventilation (SIMV) or pressure-support ventilation (PSV). However, this has not stopped manufacturers from providing these modes of ventilation, nor has it stopped clinicians from using them while delivering anesthetic during surgery.

In this chapter, the sections on pulmonary mechanics, physiology, and basic principles of mechanical ventilation delineate the technology and contemporary strategies for lung ventilation. Major features of commonly used anesthesia ventilators in the United States are described.

Of note, no chapter can substitute for the detailed information provided by each ventilator manufacturer, which is found in the educational materials and the operator’s and service manuals for each piece of equipment. The reader should refer to these documents for the most detailed pneumatic and electrical schematics.

History

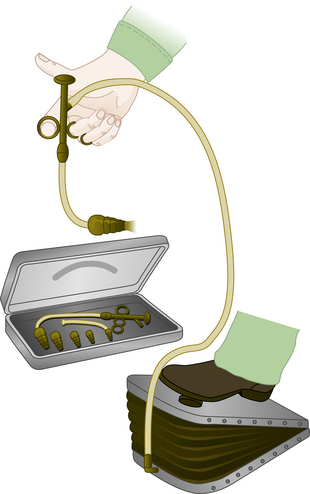

Early recorded attempts to artificially ventilate the lungs of a person date from the 1400s. Baker1 found records of mouth-to-mouth resuscitation of a newborn in 1472 and of an asphyxiated miner in 1744. Paracelsus is credited with the first use of a bellows in 1530 to artificially inflate the lungs.2 Open-chest ventilation of a dog via an endotracheal reed was described by Andreas Vesalius in 1555,3 using mouth-to-tube pressurization, but it was later replaced with bellows ventilation by Robert Hooke in 1667.4 By the late 1700s, Denmark had initiated a formal campaign and monetary reward for those using a bellows to resuscitate victims of near-drowning. The metal endoral tube, with a conical adapter for the glottic opening, was introduced in 1887 by O’Dwyer for the treatment of patients with diphtheria.5 This tube was combined with George Fell’s manual ventilating bellows and valve device6 and was used to treat opium overdose in 1891. The resulting Fell-O’Dwyer apparatus7 (Fig. 6-1) was simplified by removing the valve and placing a hole in the circuit; the hole could be occluded by the thumb during inspiration, thus providing positive-pressure ventilation and passive exhalation. In France in 1896, Tuffier and Hallion8 were able to partially resect the lung of a patient whose trachea they had intubated blindly with a cuffed tracheal tube and whose lungs they ventilated during the surgical procedure. Finally, in 1898, the first rudimentary anesthesia machine was developed by Rudolph Matas of New Orleans, who added an anesthetic vapor delivery system to the Fell-O’Dwyer apparatus, thus allowing the resection of a chest wall lesion under positive-pressure ventilation with anesthesia.9

FIGURE 6-1 Fell-O’Dwyer apparatus. (From Mushin WW, Rendell-Baker L, Thompson PW, et al: Automatic ventilation of the lungs, ed 3, Oxford, UK, 1980, Blackwell Scientific.)

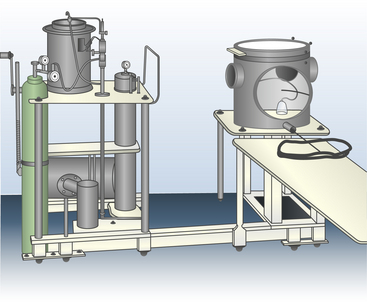

Attempting to circumvent the difficulties of tracheal intubation, in 1904, Sauerbruch developed a negative-pressure operating chamber that required the patient’s head to be sealed outside the chamber. Further development resulted in the electrically powered “iron lung” by Drinker and Shaw in 1928,10 which was widely used to treat patients with respiratory failure during the polio epidemics. In an alternative approach, in 1905, Brauer provided positive-pressure ventilation via the head, sealed within a chamber and thus eliminating the need for intubation or operating within a chamber (Fig. 6-2).11

FIGURE 6-2 Brauer’s positive-pressure apparatus. (From Mushin WW, Rendell-Baker L, Thompson PW, et al: Automatic ventilation of the lungs, ed 3, Oxford, UK, 1980, Blackwell Scientific.)

Modern techniques of endotracheal ventilation during general anesthesia were initiated by Magill in 1928 for head and neck surgery.12 The beginnings of modern mechanical ventilation are attributed to Engström and his ventilator during the polio epidemics in Denmark circa 1952.13 This ventilator was later modified for use during general anesthesia,14 which stimulated the development of a huge number of anesthesia ventilators with a wide diversity of characteristic behaviors, mechanisms, and power sources. Gradually, designs were modified and eventually replaced by pneumatically controlled and fluidically time-cycled systems that were optional accessories for the anesthesia machine. These stand-alone ventilators substituted for the reservoir bag at the connection to the breathing circuit and took on the appearance of modern “bag in a bottle” double-circuit systems.

Contemporary anesthesia machines have replaced these freestanding ventilators by integrating the fresh gas delivery system, scavenging system, and ventilator into one unit. Modern ventilators have electronically controlled circuits and, in some cases, closed feedback loops with microprocessor-regulated flow control valves. Modern ventilators allow digital and graphic displays to aid in ventilator management.

Physiology and Mechanical Concepts

The two major functions of the lung are taken into consideration during mechanical ventilation: ventilation, the elimination of carbon dioxide (CO2), and oxygenation, the intake of oxygen (O2). A clear distinction should be made between the elimination of carbon dioxide and the intake of oxygen, even though these two processes are mechanically coupled during natural, spontaneous breathing and are interrelated at the metabolic level. Each is capable of stimulating ventilation.

Carbon dioxide elimination depends on ventilation, which means the lungs are inflated with non–CO2-containing gases. The carbon dioxide gas of metabolism enters the alveoli of the lungs, and the CO2-containing gas is expelled from the lungs on exhalation. As such, the achieved ventilation determines the partial pressure of CO2 in the arterialized blood (PaCO2).

Oxygenation is best represented by the partial pressure of oxygen in the arterialized blood (PAO2). Predictable improvements in oxygenation can be facilitated by enriching the inspired gas as dictated by the alveolar gas equation:

where PAO2 is the partial pressure of alveolar oxygen, FiO2 is the fraction of inspired oxygen, PB is barometric pressure, PH2O is partial pressure of water vapor at 37° C, PaCO2 is partial pressure of alveolar carbon dioxide, and R is the respiratory quotient. Increased oxygenation also can be accomplished by increases in airway pressure, which can recruit collapsed alveoli and redistribute alveolar fluid. These changes may be largely independent of ventilation.

Carbon Dioxide Equilibrium

The quantity of carbon dioxide produced normally dictates the minute ventilation. With the exception of using cardiopulmonary bypass or an extracorporeal membrane oxygenator (ECMO), no alternative method has proved satisfactory for eliminating carbon dioxide. Breathing is essential. Normally, in the absence of disease, high altitude, and pharmacologic intervention, spontaneous ventilation results in a PaCO2 of approximately 40 mm Hg. However, the quantitative relationship between CO2 production and minute ventilation often is poorly understood.

Carbon Dioxide Production

A resting adult weighing 70 kg produces approximately 0.008 gram molecules (moles) of carbon dioxide per minute. At standard temperature (0° C) and pressure (760 mm Hg), one mole of any gas occupies 22.4 L. Therefore, 0.008 moles of carbon dioxide occupy approximately 180 mL. At body temperature (37° C), this is approximately 200 mL.

Carbon Dioxide Elimination

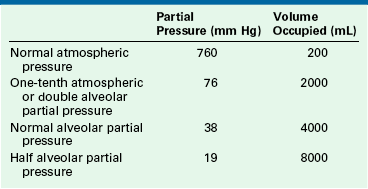

Expressing carbon dioxide production either in moles or in milliliters at atmospheric pressure provides no insight into the volume of ventilation required to maintain homeostasis. More helpful information is provided when the same quantity of carbon dioxide is expressed at different partial pressures, using Boyle’s law (Table 6-1).

TABLE 6-1

Metabolic Production of CO2 Expressed at Different Partial Pressures

Each volume represents the minimum alveolar ventilation capable of achieving that partial pressure of carbon dioxide.

The volume of carbon dioxide shown at each partial pressure in Table 6-1 is the volume occupied by the metabolic production for 1 minute (0.008 moles). At each pressure, the volume shown is the volume of carbon dioxide produced and therefore is the least alveolar ventilation per minute that is capable of eliminating the carbon dioxide produced. Any lesser alveolar ventilation is insufficient to allow the carbon dioxide to escape at that partial pressure.

The patient’s minute volume is made up of both the alveolar and the total dead space ventilation. Normally, the dead space ventilation is one third of the minute volume. For an alveolar minute ventilation of 4000 mL, the required total minute ventilation therefore is approximately 6000 mL. The mixed expired carbon dioxide has a partial pressure of approximately 27 mm Hg.

During IPPV under anesthesia, the total dead space typically increases to approximately 45% of the tidal volume. The same alveolar ventilation of 4000 mL/min thus requires a total minute ventilation of approximately 7275 mL, which will eliminate a mixed expired partial pressure for carbon dioxide of approximately 22 mm Hg.

Oxygen Uptake

At rest, the 70-kg adult human has an oxygen consumption of approximately 250 mL/min. Strictly speaking, ventilation is not essential for oxygenation. When the patient is breathing oxygen, the pulmonary reservoir represents approximately 12 minutes worth of metabolic consumption. Furthermore, if a denitrogenated apneic patient is connected to an oxygen supply (apneic oxygenation), oxygenation theoretically is unlimited.15 In that case, survival is limited by carbon dioxide accumulation, not by hypoxia.

Net Effect of Respiratory Quotient

Respiratory quotient (RQ) is the ratio between carbon dioxide production and oxygen consumption. The production of carbon dioxide, such as 200 mL/min, normally is slightly less than the oxygen consumption, at 250 mL/min (RQ: 200/250 = 0.8). This discrepancy has interesting implications. With an RQ of 0.8, the sum of the arterial partial pressures for carbon dioxide and oxygen (PaO2 [100] + PaCO2 [40] = 140 mm Hg) will always be slightly less than the humidified inspired oxygen tension (PiO2 = 0.21 × [760 − 47] = 149 mm Hg) instead of being exactly equal to it. Because the minute volume inspired is slightly greater than that exhaled, a continuing, small, net inward movement of gas into the lungs is observed. At equilibrium, the partial pressure of nitrogen, or nitrous oxide (N2O), is slightly greater in the lung than in the inspired gas and, of necessity, this causes an equal reduction in the space that would have been available for the respiratory gases, carbon dioxide, and oxygen.

Physics of Gas Flow

Each ventilator discussed in this chapter has a selection of primary variables that the user may set. These may include any of the following:

| Inspired pressure: | PI |

| Peak inspiratory pressure: | PImax |

| Tidal volume: | VT |

| Minute volume: | VM |

| Inspiratory flow: | QI |

| Frequency: | f |

| Respiratory cycle time: | Tc |

| Inspiratory pause time: | Tplat |

| Inspiratory time: | TI |

| Expiratory time: | TE |

| Inspiratory/expiratory ratio: | I:E |

As spontaneous breathing occurs, work is done to move gas into and out of the lung. This work has been designated the work of breathing (WOB). Another way to view this is the energy expended to move the gas into and out of the lungs. It is well known that the total work of breathing (WOBT) is the sum of the work related to overcoming the elastic properties of the lung and chest wall (WOBE) and the work related to overcoming the resistance aspects of the circuit, endotracheal tube, and large and small airways (WOBR). Thus,

Under normal circumstances, the work related to overcome the elastance of the lung and chest wall is nearly 70% of the total WOB; the work related to overcome the resistance of the airways is nearly 25%, and approximately 5% is related to inertial properties of the tissues and gases. Elastance (E) of the chest wall is defined as the change of airway pressure (ΔP) divided by the change in volume (ΔV):

Elastance, however, is more commonly described by the inverse, compliance (C):

Experimentally derived, formulated, and published in the 1840s by Jean Louis Marie Poiseuille (1797–1869), Poiseuille’s law identifies the relationship of gas flow (Q) directly to the pressure gradient (ΔP) and identifies an inverse relationship to the resistance (R) of the system:

This equation can be manipulated to show that:

Because the purpose of the ventilator is to perform the work of breathing, it becomes advantageous to examine these physical relationships. In so doing, a method for classifying and understanding ventilator function using the “equation of motion” has emerged.16

The force exerted by a ventilator is measured as pressure. This pressure must overcome two distinct impedances to motion during inspiration: compliance and resistance. Exhalation is passive when mechanical ventilation is used and usually remains unaccounted. The pressure required to overcome the compliance properties of the lung and chest wall can be expressed as:

where Pc is pressure compliance. A second element of pressure required to overcome the resistance is found within the breathing circuit, the endotracheal tube, and the conducting airways. The pressure required to overcome this resistance may be expressed mathematically:

where PR is pressure resistance and QI is inspiratory flow. Because the ventilator exerts pressure to overcome both the compliance and resistance, these two equations may be combined during inspiration:

where PT is total pressure and PI is inspiratory pressure, or:

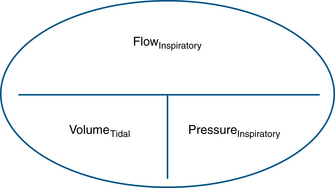

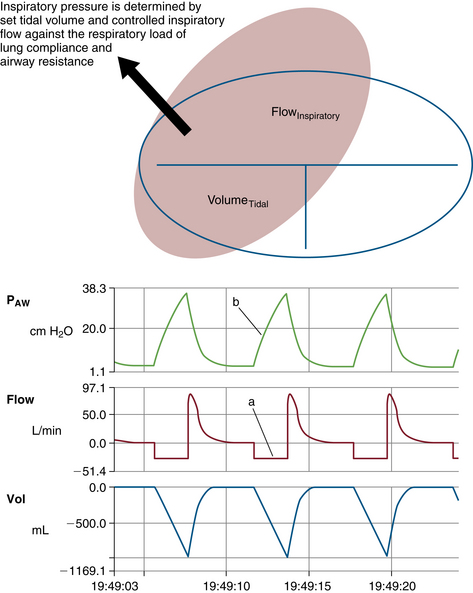

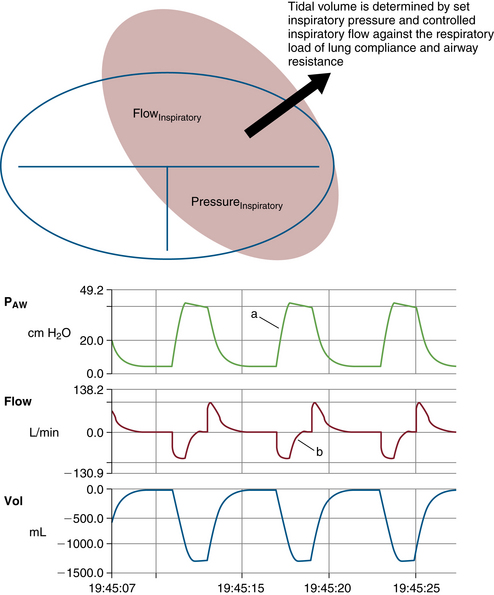

Compliance and resistance may be regarded as the “load” facing the inspiratory pressure that results in the two fundamental variables: tidal volume and inspiratory flow. Changes in inspiratory pressure result in changes in both tidal volume and inspiratory flow. Changes in a desired tidal volume can be achieved by changes in inspiratory pressure and/or flow. Changes in a desired inspiratory flow can be achieved as the result of changes in inspiratory pressure, tidal volume, or both. While using specific ventilator modes, a ventilator attempts to control the inspiratory flow rate to provide a “set” tidal volume or inspiratory pressure (Fig. 6-3). When the inspiratory flow is matched to a desired tidal volume, the inspiratory pressure varies to the given load (Fig. 6-4). When the inspiratory flow is matched to a desired inspiratory pressure, the tidal volume varies to the given load (Fig. 6-5).

FIGURE 6-4 Relationship of controlled inspiratory flow and “fixed” or “set” tidal volume. An example of fixed flow on a 3-L anesthesia circuit reservoir bag with volume control ventilation settings. Notice inspiratory flow is constant (a) and inspiratory pressure rises linearly (b). PAW, airway pressure. (From Datex-Ohmeda S/5 Collect, v4.0. 2003. Courtesy GE Healthcare, Waukesha, WI.)

FIGURE 6-5 Relationship of controlled inspiratory flow and “fixed” or “set” inspiratory pressure. An example of a set pressure limit on a 3-L anesthesia circuit reservoir bag with pressure control ventilation settings. Notice inspiratory pressure rises sharply to the set pressure limit (a) and inspiratory flow rises sharply, then decays before exhalation (b). PAW, airway pressure. (From Datex-Ohmeda S/5 Collect, v4.0. 2003. Courtesy GE Healthcare, Waukesha, WI.)

Interdependence of Ventilator Settings

Many of these respiratory variables are interdependent, such as minute volume, tidal volume, and respiratory rate (VM = VT × f). In some ventilators, the tidal volume is determined by dividing the minute volume by the rate:

Tidal volume is also related to the inspiratory flow rate and the inspiratory time:

An inspiratory pause (plateau time [Tplat]) is a part of the inspiratory time. Because the inspiratory pause makes no contribution to the tidal volume, the equation for tidal volume may be modified:

Clinicians are also concerned about the relationship between inspiratory and expiratory time because the I:E ratio and the absolute times TI and TE affect ventilation and oxygenation. This ratio and the absolute time of inspiration are related to frequency and may be expressed mathematically.

Frequency determines time of the respiratory cycle (Tc), usually expressed in seconds, by the following relationship:

It follows that 60/f is equal to the inspiratory and expiratory times combined:

The relationship between TI and TE is conventionally expressed as the I:E ratio with 1 as the numerator. This ratio may be derived mathematically as follows, where RI:E equals I:E ratio:

(1) Seconds per minute devoted to inspiration:

(2) Seconds per minute devoted to exhalation:

(3) Dividing (1) by (2), the I:E ratio:

(4) The frequency and the inspiratory time can be derived by rearranging (3):

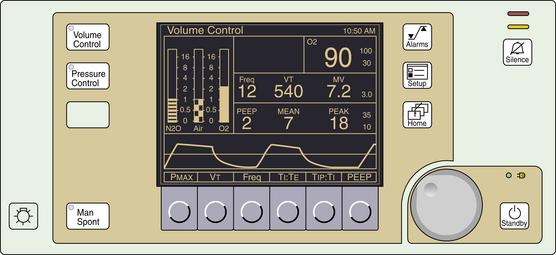

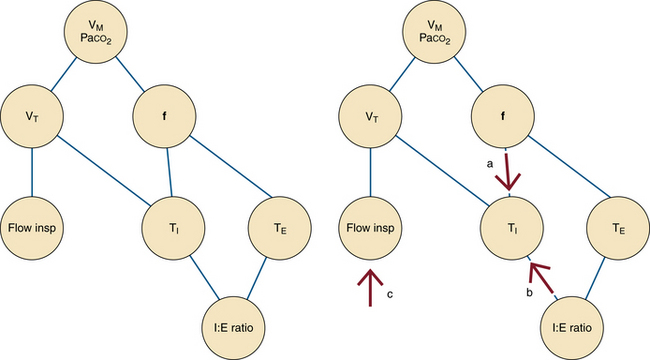

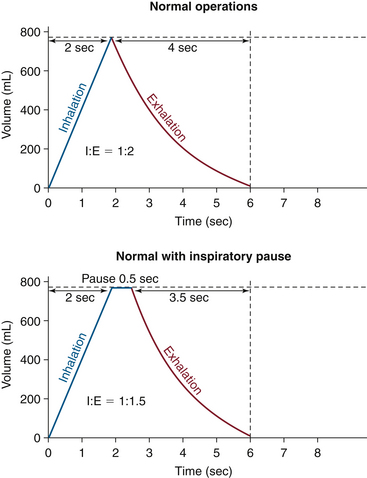

Depending on the manufacturer and the particular model of ventilator, the clinician must choose the RI:E (I:E ratio), mean QI (average inspiratory flow rate), or both. The reader is encouraged to study the manufacturer variations shown in Figures 6-6 to 6-13.

FIGURE 6-6 Interdependence of ventilator settings. VM, minute ventilation; VT, tidal volume; f, frequency or respiratory rate; Flow insp, inspiratory flow; Paco2, partial pressure of arterial carbon dioxide; TI, inspiratory time; TE, exhalation time; I:E ratio, inspiratory time to exhalation time ratio. Notice that the frequency and the I:E ratio are independent of one another. If tidal volume is fixed, changes in the respiratory rate (a) or I:E ratio (b) alter the inspiratory time. The inspiratory flow must then be adjusted (c) to maintain the fixed tidal volume at the new inspiratory time.

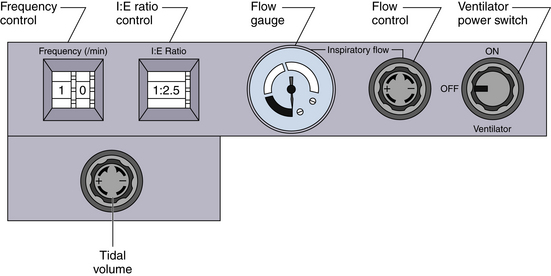

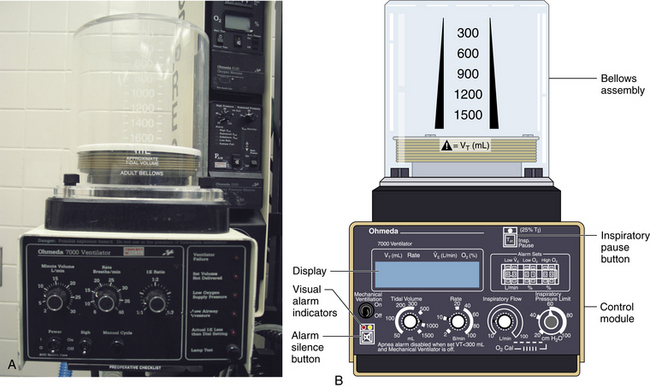

FIGURE 6-7 The Datex-Ohmeda 7000 ventilator (GE Healthcare, Waukesha, WI) requires the user to set minute volume and rate. Tidal volume must be calculated. Numbered components indicate the following: set minute volume (1), set frequency (2), set I:E ratio (3), warning lamps (4), switch to test the warning lamps (5), ventilator preoperative checklist (6), switch to activate one manual cycle (7), sigh function on/off (8), and power on/off switch (9).

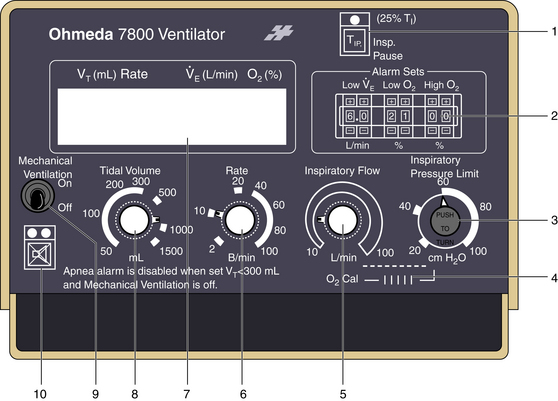

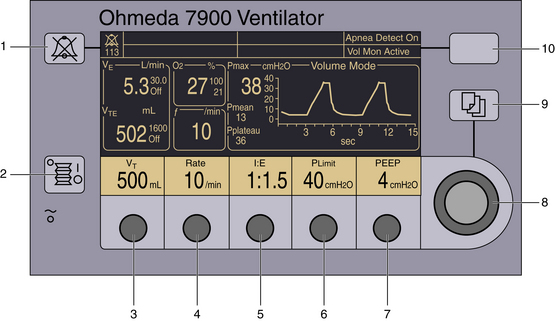

FIGURE 6-8 The Ohmeda 7800 ventilator (GE Healthcare, Waukesha, WI) allows the user to select inspiratory flow (5) to determine the rate at which the selected tidal volume is delivered. This selection alters the I:E ratio, which is announced in the liquid crystal display (7), which also displays ventilatory parameters and alarms. Compared with the Ohmeda 7000, the Ohmeda 7800 adds a pressure limiter (3) and a fixed inspiratory pause option (1). Additional numbered components include alarm limit sets (2), oxygen calibration dial (4), set frequency (6), set tidal volume and apnea alarm disable (8), power on/off switch (9), and alarm silence button (10).

FIGURE 6-9 The Ohmeda 7900 ventilator (GE Healthcare, Waukesha, WI) allows the user to set desired tidal volume (as shown) or inspired pressure (3) in the volume-controlled or pressure generator modes, respectively. Compared with the Ohmeda 7800 ventilator, the user selects the I:E ratio (5) instead of the flow. Positive end-expiratory pressure (PEEP; 7) is an integral feature on the control panel. Dedicated displays of measured parameters are demonstrated. Other numbered components include the audible alarm silence button (1), mechanical ventilation on/off switch (2), select frequency (4), select inspiratory pressure limit (6), adjustment knob for the corresponding selection (8), select menu (9), and select apnea–volume alarm combinations (10).

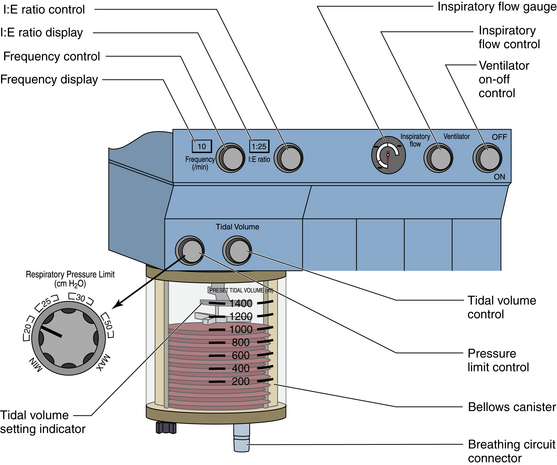

FIGURE 6-10 A unique feature of the Dräger AV ventilators (Dräger Medical, Telford, PA) is that both the inspiratory flow and the I:E ratio may be set by the user, creating a variable inspiratory pause within the preset inspiratory time.

FIGURE 6-11 The Dräger AV-2 ventilator (Dräger Medical, Telford, PA) control panel adds a pressure limiter and digital displays of frequency and I:E ratio. The inspiratory flow and I:E ratio are set by the user, creating a variable inspiratory pause.

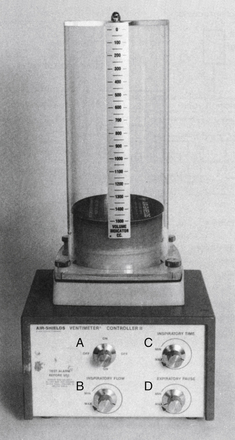

FIGURE 6-13 The Air-Shields Ventimeter Controller II. Shown are the on/off switch (A), the inspiratory flow control (B), the inspiratory time control (C), and expiratory pause control (D).

The following example demonstrates how frequency, tidal volume, flow, and I:E ratio are interdependent. Assume that in a 60-kg patient VT is 600 mL and f equals 10 breaths/min. As such, the cycle time is fixed at 6 seconds.

By choosing an I:E ratio of 1:2, the inspiratory time becomes fixed at 2 seconds, which mandates a mean inspiratory flow rate of 300 mL/sec or 18 L/min (300 mL/sec × 60 sec/min = 18 L/min). Choosing an I:E ratio of 1:1 increases the inspiratory time to 3 seconds, resulting in an inspiratory flow rate of 200 mL/sec or 12 L/min. An I:E ratio of 1:3 reduces the inspiratory time to 1.5 seconds, resulting in an inspiratory flow rate of 400 mL/sec or 24 L/min.

This situation is complicated somewhat by the selection of an inspiratory pause because the respiratory gases are not in transit into or out of the lungs. Exhalation begins when gases start leaving the lungs, so the inspiratory pause is considered part of the inspiratory phase of the respiratory cycle. When incorporated into the original example, with an I:E ratio of 1:2, the inspiratory time of 2 seconds would result in a mean inspiratory flow rate of 300 mL/sec or 18 L/min. In a situation in which Tplat equals 25%, TI is selected, and 25% of the original inspiratory time is added to the inspiratory time. This results in a changed I:E ratio. In this example, the inspiratory time is 2 seconds and 25% of the inspiratory time is 0.5 seconds, which results in a total inspiratory time of 2.5 seconds. Superficial calculations of inspiratory flow rate would suggest 240 mL/sec or 14.4 L/min flows. However, the ventilator would continue to deliver the inspiratory flow at 300 mL/sec or 18 L/min. Inspiratory flow is stopped at 2 seconds, achieving the 600 mL tidal volume, but exhalation occurs 0.5 seconds later. As such, the I:E ratio is changed without affecting the tidal volume, respiratory rate, or inspiratory flow rate. This pause at end inhalation allows for a mild increase in mean airway pressure, increased alveolar recruitment, and improved oxygenation (Fig. 6-14).

FIGURE 6-14 The effect of the inspiratory pause on the I:E ratio. (From Explore the anesthesia system. 1996, Ohmeda [now GE Healthcare, Waukesha, WI], pp 6-18.)

Primary selection of an inspiratory flow mandates the inspiratory time for the given 600 mL VT and thus determines the I:E ratio. For example, selecting a flow of 18 L/min (300 mL/sec) mandates an I:E ratio of 1:2 (VT /QI = TI):

At f = 10, each cycle is 6 seconds. Therefore expiratory time equals 4 seconds. The I:E ratio is 2 seconds relative to 4 seconds, or 1:2.

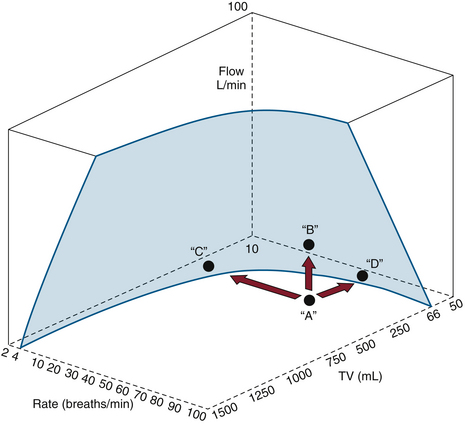

Some combinations of settings may exceed the capability of the ventilator. For example, a very low flow setting may not be able to deliver the 600 mL within the allotted 6-second cycle time. The alarm “VENT SET ERROR” will appear in the Datex-Ohmeda 7800 ventilator (GE Healthcare, Waukesha, WI) display (Fig. 6-15). In the Datex-Ohmeda 7800, with QI equal to 18 L/min, selection of the inspiratory pause of 25% will prolong the TI to 2.5 seconds, thus changing the I:E ratio to 1:1.4.

FIGURE 6-15 The limitations of the Datex-Ohmeda 7800 ventilator, illustrating the relationships among flow, frequency, and tidal volume. Only combinations of settings behind the shaded area are possible. In situation A, the message “VENT SET ERROR” appears and may be corrected by decreasing the rate C, increasing the flow B, or decreasing the tidal volume to D. (Courtesy GE Healthcare, Waukesha, WI.)

Other ventilators allow the selection of the I:E ratio and flow simultaneously. Three situations may result: 1) flow will be inadequate to deliver the selected tidal volume, 2) flow can be increased to create a variable end-inspiratory pause, and 3) flow can be just enough to depress the bellows to the bottom, thus delivering the desired tidal volume without a pause.

The final primary variable is the inspiratory pressure (PI). This variable can be set on some ventilators as a primary variable if the ventilator is in a pressure mode. In so doing, airway pressure increases very rapidly to the set level and is maintained at that level for the duration of the inspiratory period. This behavior must be distinguished from that of an airway pressure limiter, a passive device that does nothing more than prevent airway pressure (PAW) from exceeding a certain value. A Venturi ventilator can be set to function like a pressure generator if the flow is set to a high level and the pressure limiter is carefully adjusted to the desired peak airway pressure.

Lung Function During Anesthesia and Mechanical Ventilation

During anesthesia with a tracheal tube, lung function is adversely affected by many factors. Most of these factors are related to the physical aspect of a tracheal tube: retention of secretions as a result of cough suppression, interference and damage to the mucociliary elevator, increased insensible water loss by lack of humidification, inspissation of secretions by dry gases, and heat loss in exhaled gases. In addition, an increase in ventilation/perfusion (V/Q) mismatching occurs from changes in physiologic and mechanical dead space. The work of breathing may be increased from resistance changes to load related to the inner diameter and length of the tracheal tube.

Tracheal suctioning, the solution to the problem of airway secretions, has mixed risks and benefits. The removal of secretions from airways can improve oxygenation and ventilation, but the act of suctioning the secretions can cause negative airway pressure, resulting in atelectasis and entrainment of nitrogen that reduces the fraction of inspired oxygen. In addition, direct airway irritation by instrumentation can cause coughing and straining that can transiently affect the cardiac output and blood pressure.

IPPV causes an increase in intrathoracic pressure during inspiration. Elevated intrathoracic pressures can decrease the blood flow returning to the heart from extrathoracic blood vessels, which in turn decreases cardiac output. Venous return also can be decreased by positive end-expiratory pressure (PEEP), which increases intrathoracic pressure during exhalation.

Lung function can be improved by the use of a tracheal tube. Tracheal intubation can protect the airway from oral and gastric secretions, especially if a cuffed endotracheal tube is used, and it can establish a patent conduit for ventilation to occur. The latter occurs when upper airway obstruction is present. Mechanical ventilation can reduce the work of breathing and allow fatigued respiratory muscles a chance to recover. Mechanical ventilation allows consistent and predictable ventilation patterns, which removes the need for an anesthesiologist to ventilate manually for long periods. This also makes it possible to change ventilation strategies in response to changes in the surgical process, patient condition, and indicators of oxygenation and ventilation, such as capnography, oximetry, blood gases, and mechanical parameters that include airway pressure and resistance and lung compliance. In specific circumstances, appropriate modes of ventilation can improve the function of an abnormal lung during anesthesia. Finally, the delivery of medicines such as potent inhalational agents, helium, and other aerosolized substances through the tracheal tube with the aid of mechanical ventilation can relieve bronchospasm.

Lung Protection Strategies

Institution of IPPV is associated with the ever-present risk of traumatic lung injury. Barotrauma, or injury related to pressure, can be grossly manifested as a pneumothorax or more subtly as physiologic and pathologic changes related to alveolar overstretching. Volutrauma, injury related to volume, also can cause alveolar overstretching. Damage related to shear stress from the opening and closing of the alveoli, called atelectrauma or shear trauma, can be caused by both pressure- and volume-related changes. Airway irritation that causes patient/ventilator dissynchrony—coughing, bucking, and straining—can result in sharp changes in airway pressure, which can cause lung injury. Usage of PEEP can lessen the injury from shear trauma but also can result in increases in physiologic dead space and reduced cardiac output.

Disease states that affect the uniformity of the lung can increase the risk of lung injury. This happens when small segments of the lung have reductions in compliance compared with their normal counterparts. Previous assumptions about the relatively predictable distribution of the volume, pressure, and perfusion to the lung segments may no longer hold true; nondiseased segments receive a greater share of the tidal volume and effects of the inspiratory pressure and PEEP. As a result, these “good” lung segments can be injured, and physiologic changes related to V/Q mismatch maybe exaggerated. This can be seen in patients with congestive heart failure, pneumonia, and acute respiratory distress syndrome (ARDS).

Large tidal volumes (15 to 20 mL/kg) also have been used during anesthesia to maintain alveolar distension. Although this strategy effectively prevents atelectasis and reduces shunt fraction, it is now recognized as a potential cause of barotrauma. Overdistension of healthy alveoli can cause disruptions of the alveolar-capillary membrane and lead to pulmonary interstitial emphysema and pneumothorax. As already stated, the presence of diffuse lung disease may compound injury to remaining healthy alveoli. Tidal volumes of 6 to 8 mL/kg are now recommended, with the addition of PEEP.17,18

Complementing the recommendation of normal tidal volumes, safe peak inflation pressures now dominate ventilation strategies. Studies show that maximal alveolar pressures only slightly greater than 30 to 40 cm H2O may be associated with lung injury.17 Recent designs of anesthesia ventilators have all incorporated peak airway pressure limiters.

Optimal PEEP recruits collapsed alveoli and maximizes functional residual capacity (FRC). However, increases in PEEP beyond this point may overdistend patent alveoli without further recruitment of others. New strategies analyze static pressure–volume plots to determine optimal PEEP and safe peak inspiratory pressures. Optimal PEEP is usually 5 to 15 cm H2O.17

For the past 10 years, clinicians have been reducing tidal volumes even further for patients with acute lung injury (ALI) or ARDS. A landmark paper from the ARDS Network showed a reduction in mortality rate in a group with lower tidal volumes (6 mL/kg) compared with those in a control group (12 mL/kg).22 Ventilator settings that result in injury are attributed to diffuse alveolar damage that causes pulmonary edema, activation of inflammatory cells, local production of inflammatory mediators, and leaks of these mediators into the systemic circulation.23 Prospective studies are lacking to examine the use of lung protective strategies in the OR for non-ALI patients. The few randomized studies that have been done do not confidently demonstrate benefits in the OR, and some authors still recommend the avoidance of high plateau pressures (>20 cm H2O) and high tidal volumes (>10 mL/kg) in this patient population. The objective of this strategy is to minimize regional end-inspiratory stretch and thereby reduce alveolar injury and inflammation.23

Caution with tidal volumes and peak airway pressures is associated with an increased incidence of hypercapnia. Permissive hypercapnia promises to reduce ventilatory complications without adverse effects.19 Humans seem to tolerate respiratory acidosis well, with an arterial pH of 7.15 and a PaCO2 of 80 mm Hg. This strategy may be contraindicated in patients with increased intracranial pressure, recent myocardial infarction, pulmonary hypertension, or gastrointestinal bleeding.19 This is because acute increases in PaCO2 increase sympathetic activity, cardiac output, pulmonary vascular resistance, and cerebral blood flow and also may impair central nervous system (CNS) function.19

Inverse ratio ventilation (IRV) originated in the early 1970s as a method to improve oxygenation in neonates with hyaline membrane disease20 and was later extended to adults with ARDS. Although ratios were as high as 4:1, the benefits of this mode depend more on an absolute prolongation of inspiratory time in combination with a decreased peak inspiratory pressure. Typical I:E ratios of 1:2 to 1:4 have been lengthened to 1:1 or greater. The objective is to increase mean airway pressure and minimize peak pressure; the desired outcome is recruitment of collapsed alveoli without overdistension. Mean airway pressure directly corresponds with alveolar recruitment, reduction in shunt fraction, and oxygenation. Clinical evidence supports the contention that shunt fraction is reduced and oxygenation is improved, although modestly.17 Because pressure control is the desired outcome, this mode of ventilation is more commonly applied with pressure generators. Caution is advised when using IRV because this strategy may not allow adequate alveolar emptying, thus causing “breath stacking” and auto-PEEP. In addition, IRV is contraindicated in obstructive lung disease, such as asthma. It also may cause hypotension from a reduction in venous return since there is a higher inspiratory pressure for a longer portion of the respiratory cycle.

High-frequency ventilation (HFV), defined below, may be an applicable strategy during anesthesia, although some anesthesia ventilators are capable of rates only to 100 breaths/min. The conceptual advantage of HFV is a lower peak airway pressure combined with nonbulk flow of gas to provide a motionless surgical field. This technique has not proven clinically advantageous in patients with respiratory failure, but it is helpful in patients with large pulmonary air leaks. In addition, pulmonary complications in neonates may be reduced with this strategy.21

Classification, Special Features, and Modes of Ventilation

Historically, many different anesthesia ventilators have been produced over the years. Many of them incorporated features that are no longer considered valuable, but these serve in the general description and understanding of ventilator function. Commonly, such things as ventilator mechanisms, cycling parameters, and special clinical features were used to classify anesthesia ventilators.

Power Source

Most ventilators today function in an environment where electricity and compressed gases are readily available. In the past, however, some ventilators were designed to function solely on pneumatic gases. Currently, the only ventilators that function solely on pneumatic gases are not anesthesia delivery systems; these pneumatically powered ventilators are used in patient transport and in magnetic resonance imaging suites. Ventilators that use the bag-in-a-bottle design commonly have a double circuit in which a high-pressure driving gas, electrical circuits, and solenoids are used to achieve ventilator function. Some newer ventilators use electricity exclusively to drive the ventilator, which spares gas use for the patient.

Drive Mechanism

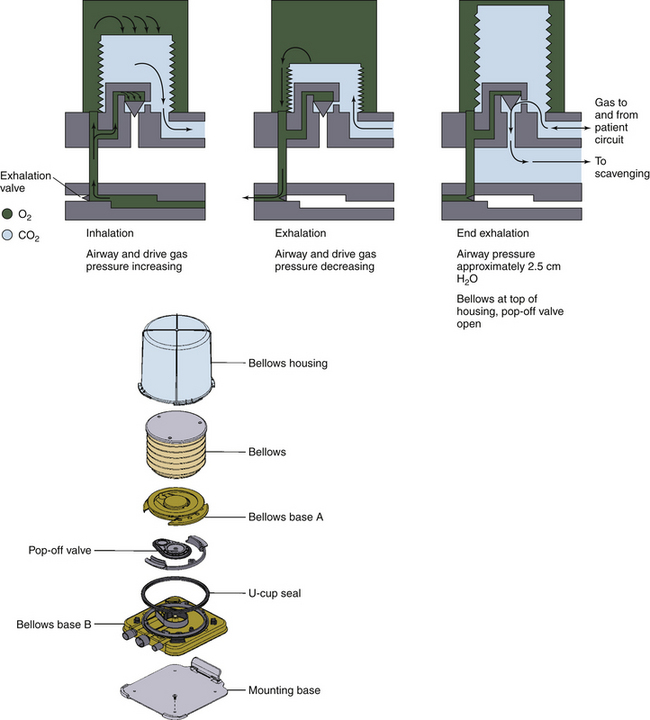

Classification of ventilators has been reduced to those that push or drive the patient gas to the patient, which is done by either a bellows or a piston.

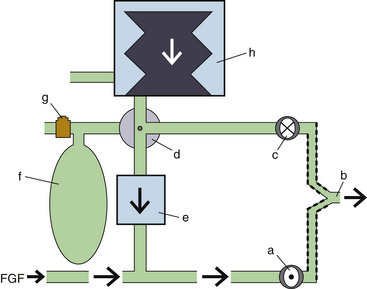

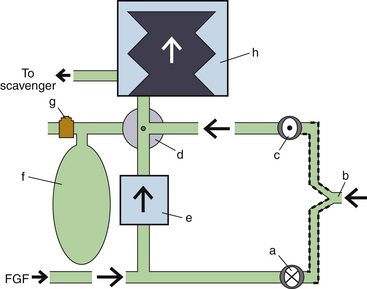

Bellowed Ventilators

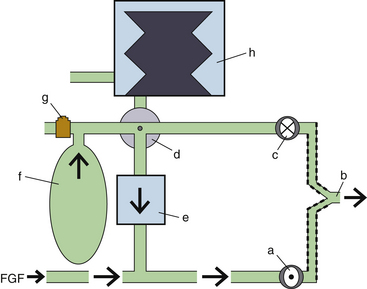

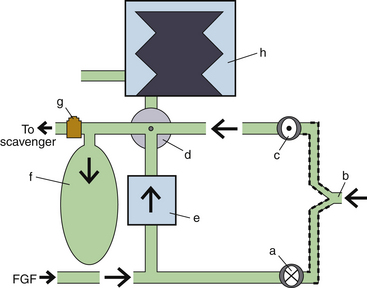

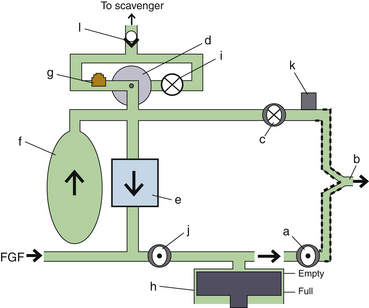

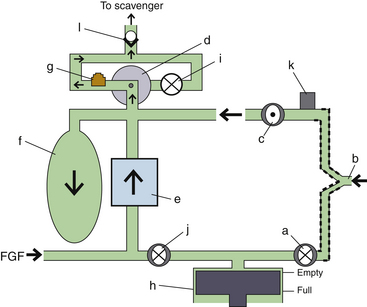

Bellowed ventilators have used two main varieties of bellows designs over the years: the ascending, or standing, bellows and the descending, or hanging, bellows. The designation of ascending or descending was based on bellows movement on exhalation; an ascending bellows moves up during exhalation (Fig. 6-16), and a descending bellows moves down (Fig. 6-17).

FIGURE 6-16 Bag-in-a-bottle bellows design, ascending bellows variety.

Ohmeda 7000 ventilator (left); illustration of Ohmeda 7800 ventilator (right) (GE Healthcare, Waukesha, WI). The bellows is contained within a clear housing, and a drive gas pushes the gas inside the bellows through the circuit. The bellows displayed in the images are deflated.

FIGURE 6-17 Bag-in-a-bottle bellows design, descending bellows variety. Shown is the Datascope Patient Monitoring Anestar anesthesia machine (Mindray North America, Mahwah, NJ) with descending bellows. The bellows (arrow) are in the inflated position.

In the event of a circuit disconnect or significant leak, an ascending bellows would not fill or would improperly fill during exhalation. This provides clinicians a visible monitor of ventilator function. Because of the improved patient safety, this type of bellows generally is preferred, but does not represent a standard according to the latest document by the American Society for Testing and Materials (ASTM F1109-90).24 The ECRI Institute has published a commentary and recommendations for hanging bellows in its Health Devices Alerts (1996-A40).

The hanging bellows, which typically is weighted, could fill whether a circuit disconnect, leak, or normal exhalation was present. Room air could enter the circuit and allow the bellows the ability to return to its filled position. In association with fresh gas decoupling, hanging bellows ventilators rely on a separate reservoir bag to detect leaks and inadequate fresh gas flow (FGF).

Bellows designs are not without inherent problems. Because a high-pressure gas typically is used to drive the bellows, a hole or perforation in the bellows can subject the patient to driving gas pressures and result in barotrauma. In addition, mixing of the patient circuit gas with the driving circuit gas may cause unpredictable concentrations in oxygen. Typically, 100% oxygen is used as the driving circuit gas. When high oxygen concentrations are undesirable or the potential for an airway fire exists, leaks into the patient circuit gas may cause disastrous consequences. When air is used as the driving circuit gas, unexpectedly low concentrations of oxygen may be observed. In both circumstances, patient awareness may occur because the driving gas may dilute the intended gas concentrations of inhaled anesthetics to be delivered to the patient. In addition, hypoventilation may occur if the bellows is not properly seated inside the bellows assembly.

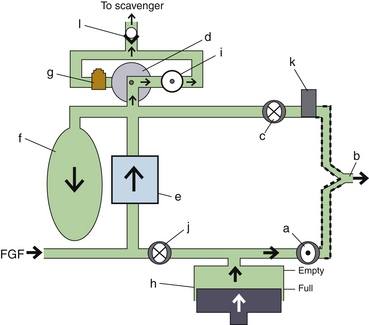

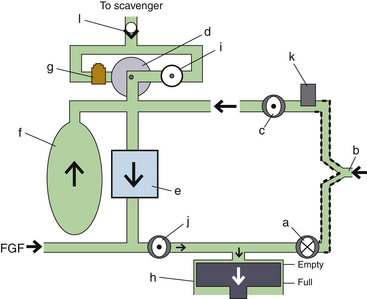

Piston Ventilators

Piston ventilators rely on a piston-cylinder configuration, in which an electric motor is used to drive or displace the piston within the cylinder to cause gas flow. Tidal volume accuracy is believed to improve because the precise position of the piston during inspiration is monitored from start to finish; the motor returns the piston to the filled position prior to the next delivered breath. The drive motor requires maintenance and usage monitoring for good function because ventilator failure has been reported from worn motor parts. A leak occurring at the piston diaphragm could cause a loss of circuit gases to the room with hypoventilation during inspiration. Entrainment of room air into the patient circuit could occur as the piston returns to the filled position. Some recent designs have placed the piston ventilator within the workstation housing to make visible operation impossible. Piston-driven bellows currently manufactured by Dräger Medical (Telford, PA) have placed the piston in both vertical and horizontal positions in different models. Such systems use fresh gas decoupling with a separate reservoir bag, which is monitored for circuit leaks or inadequate FGF.

Cycling Behavior

Cycling behavior is believed to be one of the most complicated concepts in ventilator classification and description. In a normal ventilator breath, two significant events occur: inspiration and exhalation. However, cycling behavior describes the event that transitions the ventilator from exhalation to inspiration and from inspiration to exhalation. In sequence, the ventilator cycles from exhalation to inspiration, inspiration occurs, the ventilator cycles from inspiration to exhalation, and exhalation occurs. For most modern anesthesia ventilators, respiratory rate and I:E ratio are set in controlled modes, either by volume control ventilation (VCV) or pressure control ventilation (PCV); time cycles the breath from exhalation to inspiration and from inspiration to exhalation. A trigger can be used to initiate inspiration on spontaneous patient effort in pressure support ventilation (PSV). The trigger, an observed parameter to allow inspiration to occur, can use pressure, volume, or flow values. As will be seen, the method of delivering the inspired breath also can be manipulated. Cycling from inspiration to exhalation can occur as a result of achieving a set volume, pressure, flow, or time.

Exhalation typically is a passive event. Pressures in the airway can be manipulated during exhalation by the addition of PEEP. More recent developments in ventilator cycling allow the cycling from exhalation to inspiration to include uses of airway pressure, volume, and flows in the ICU. However, most anesthesia ventilators still use time as the determinant to cycle from exhalation to inspiration.

Many machines can function in at least two modes; the most common example is the ventilator that normally cycles when a given time or tidal volume is reached. In the Datex-Ohmeda 7800 series, reducing the pressure limit makes the ventilator cycle when a given pressure is reached. By contrast, in the Dräger AV-2+, the inspiratory phase is not ended; the bellows is held in its compressed state by the continuing flow of drive gas, which escapes to the atmosphere through the pressure-limiting valve. These mechanisms afford a poor basis for classification because, as demonstrated, they may not indicate functional behavior.

Inspiratory Flow

The inspiratory flow classification describes the method used to make a breath: either a flow generator or pressure generator. A flow generator is used in ventilation when the inspiratory waveform is controlled around the use of a high-pressure source; the source in this case is typically greater than five times the airway pressure. A pressure generator is used when the pressure waveform is controlled around the use of a low-pressure source, usually near or moderately higher than the airway pressure.

When a high-pressure source is used, changes in patient compliance and resistance have little effect on the inspiratory flow waveform. As such, a fixed or constant flow can be established to generate a reliable tidal volume breath for a given inspiratory time. This type of ventilator is called a constant flow generator.

With a low-pressure source, changes in patient compliance and resistance affect the inspiratory waveform. As a result, the pressure waveform is controlled because it is not affected by patient changes and the use of a low-pressure source. Mechanisms used to achieve this behavior of constant airway pressure during the inspiratory period include the use of a spring or weight on the bellows. This is what is known as a constant-pressure generator. On inspiration, a large pressure gradient exists from the ventilator to the alveoli that results in high initial gas flows. Rising gas volumes in the lung slowly equilibrate pressures between the ventilator and lung to cause a diminishing inspiratory flow; the delivered tidal volume is the result of the variable flow related to the equilibrating pressures between the ventilator and lung and the time allotted for inspiration to occur.

Some flow generators can vary the inspiratory flow to provide different flow waveforms; that is, increasing flow (ascending ramp), decreasing flow (descending ramp), or sinusoidal flow may be selected. This type of ventilator is called a variable-flow generator. Modern flow generators can provide pressure generator behavior by using negative feedback to vary the orifice of the inspiratory flow control valve during inspiration.

Classification by inspiratory flow should not be confused with the volume- or pressure-control modes of ventilation. Modern ventilators can now switch between flow and pressure generator methods. In addition, both flow and pressure generators can achieve the same modes of ventilation by advances in sensor application and electronic feedback control.

Control of the Pressure and Flow Waveform During Ventilation

The pattern of ventilation occasionally used has a critical influence on lung function. The most common example in the OR is the hypotension that accompanies hyperventilation. In critical care, greater attention is given to optimizing lung function by appropriate selection of the inspiratory waveform. For example, several advantages have been proposed for using a decelerating waveform: the maximum pressure is minimized, the risk of barotrauma is diminished, alveoli are kept expanded, V/Q ratios are more uniform, and distribution of gas within the lung is facilitated.

Controlled ventilation also tends to affect venous return and cardiac output. To a large extent, the best strategy to optimize cardiac output is the reverse of that which promotes improved lung function. A relatively short inspiratory period, with no time for distribution and no plateau, will have the least effect on the mean intrathoracic pressure and therefore on venous return.

Debate about the potential benefits of variation in the inspiratory waveform has persisted for at least 35 years. The expense and complexity required to achieve such waveforms have been critically discussed since the early 1960s. In the OR, fine control of the inspiratory waveform usually is not provided or needed. To this day, many anesthesia ventilators offer no control of the inspiratory waveform, and the anesthesiologist must occasionally approximate a desired pattern with the equipment available.

Constant Inspiratory Flow

Most anesthesia ventilators are powered by a high-pressure gas source. For practical purposes, flow is not affected by the patient, and it remains constant during the inspiratory period (see Fig. 6-4).

Declining Inspiratory Flow

Declining inspiratory flow allows time for gas redistribution at the end of inspiration. An anesthesia ventilator can be set to approximate this pattern by continuing the normal inspiratory flow rate until the lung is filled and then maintaining a plateau for distribution; this minimizes the time required to fill the lung and maximizes the time for redistribution. Many anesthesia ventilators have this option. It is very rare for a patient to be so dependent on a critical pattern of decelerating inspiratory flow that this approximation does not suffice (see Fig. 6-5).

Accelerating Inspiratory Flow

An accelerating inspiratory flow pattern is intended to achieve ventilation while minimizing the effect on intrathoracic pressure. In a patient in whom this is beneficial, the anesthesia ventilator can approximate this pattern by prolongation of the period for exhalation, followed by a rapid inspiration with no plateau. The prolongation of the expiratory period maximizes the time for venous return. The time devoted to filling the lungs, which adversely affects venous return, is reduced to the minimum. No data supporting the use of accelerating inspiratory flow are available.18

Sinusoidal Inspiratory Flow

Once promoted as mimicking normal ventilation, the sinusoidal inspiratory flow pattern was provided by the Engström and Emerson piston ventilators. Some thoracic surgeons preferred this pattern because it provided a smoother transition from inspiration to exhalation and vice versa. Ventilators that offer this pattern of inspiratory flow are no longer in general use.

Improvement in Control

Closed-loop negative feedback can be used to improve performance in a controlled category, such as flow or volume. Some newer machines measure either the machine’s delivered flow or the delivered tidal volume; these measures allow more accurate control of the ventilator to improve its performance. Unfortunately, better control of the volume or flow at the ventilator still tends to be offset by the compliance and resistance of the circuit itself because the measurements of flow and volume are not routinely made at the tracheal tube. The most modern technique to date uses automatic self-measurement of the ventilator and breathing circuit compliance; this enables accurate calculation and delivery of flow and tidal volume, as seen in newer GE Healthcare and Dräger workstations. Other preexisting technologies, such as spirometry, use sensors placed at the endotracheal tube that enable accurate measurement of delivered and exhaled volumes, pressure, compliance, and resistance. However, such technologies are not always set up to influence the ventilator automatically.

In units with closed feedback loops, microprocessors attempt to maintain the designated variable constant by processing data hundreds of times per second and by regulating the flow control valve with equal frequency. Feedback may be helpful in the midst of changing clinical conditions such as bronchospasm, secretions, or even a leak in the system. Open-loop systems cannot compensate for these external loads and eventually fail to deliver the prescribed parameter, which requires vigilance and adjustments by the anesthesiologist.

Special Ventilator Features

Many other valuable features may be available on a given ventilator. These features are less suitable as tools to classify ventilators, even though they may be critically important when managing a particular patient.

Inspiratory Manipulation

Inspiratory Plateau or Inspiratory Hold

A tidal volume maintained after the inspiratory flow ceases, a so-called plateau or inspiratory hold, provides an opportunity for gas to redistribute within the lung. This maintained pressure may also improve gas exchange by keeping alveoli expanded for a longer period, thus reducing shunt fraction. In addition, the pause facilitates the measurement of static lung compliance. The potential penalty of a plateau, particularly in a hypovolemic patient, is that the increased intrathoracic pressure may impede venous return and decrease cardiac output. Inspiratory hold also affects the I:E ratio (see Fig. 6-14).

Inverse Ratio Ventilation

Modern anesthesia ventilators have recently offered IRV as a means of increasing mean airway pressure without increasing peak airway pressure.25,26 Inverse ratio ventilation is defined as an I:E ratio greater than 1:1. It has physiologic effects similar to the inspiratory pause described above. The ratio may be inverted in ventilators that use both flow generator (FG) or pressure generator (PG) modes. When FG-IRV is used, the I:E ratio can be inverted only by decreasing the mean inspiratory flow or by adding an end-inspiratory pause. For the same minute ventilation and I:E ratio, the inspiratory pause provides a greater mean airway pressure than does the lower flow rate of the first option.25-27 When using IRV, caution is advised to prevent breath stacking and auto-PEEP. This can occur if there is inadequate time for exhalation; using IRV with a PG merely prolongs the inspiratory time.

Expiratory Manipulation

Positive End-Expiratory Pressure

Most anesthesia ventilators now routinely provide PEEP. At the end of each breath, the pressure is commonly maintained at an end-expiratory pressure of 2 to 4 cm H2O above zero because of the weight of valves and bellows, although some anesthesia ventilators provide a direct control to set additional PEEP. When lung function is less than optimal, PEEP may be added to improve oxygenation by alveolar recruitment. This is a more logical response to desaturation than merely increasing the inspired oxygen concentration because it is better to improve the function of the lung than to conceal the evidence of dysfunction. Because PEEP can affect the venous return to the heart, careful monitoring of the hemodynamics is advised.

Expiratory Retard

The introduction of a constrictive orifice during exhalation can benefit some patients with advanced lung disease. This is due to the fact that expiratory retard will decrease the expiratory flow rate and allow more laminar flow and better emptying of the lung. This modality can be useful in patients with severe bronchoconstriction, such as those with status asthmaticus. It is similar to the pursed-lipped breathing seen in asthmatics; air trapping is minimized, and exhalation may, paradoxically, be improved. This modality is rarely incorporated in anesthesia ventilators today because it carries the risk of incomplete exhalation (breath stacking) if the frequency is suddenly increased, which would cause a potentially dangerous high pressure. The clinician must always be sure that the end-expiratory pressure is zero.

Interactions with the Breathing System

Fresh Gas Flow

In combination with oxygen, anesthetic gas typically flows continuously from the common gas outlet of the anesthesia machine into the breathing circuit. In some ventilators, FGF is directly delivered into the ventilator bellows, which is preloaded under a certain degree of spring tension, called the working pressure. These ventilators (e.g., Servo Ventilator 900C [Siemens-Elema AB, Solna, Sweden]) store fresh gas for every cycle, mandating an FGF at least equal to the minute volume. FGF commonly contributes to actual delivered tidal volume if it continues to flow into the breathing circuit during the inspiratory phase. This contribution is measured by:

where VFGF is the volume of FGF. For example, at an FGF of 3 L/min and a TI of 2 seconds, the FGF contribution to tidal volume is calculated as follows:

New designs of ventilators offer fresh gas uncoupling by electronically interrupting or diverting the FGF during the inspiratory phase. Others compensate for the FGF by first measuring total delivered flow and then adjusting the next breath through servo mechanisms.

Scavenging Systems

Modern dual-circuit ventilators have an integral ventilator pressure relief valve at or inside the bellows that is sealed during inspiration and at the beginning of exhalation, until the ascending bellows has been refilled. This ventilator pressure relief valve provides a minimum mandatory level of PEEP, usually 2 to 3 cm H2O, and then releases anesthetic gas into the scavenging system once the bellows is full. Typically, this waste gas travels directly to the scavenging system, although newer technologies, such as those designed into the Datex-Ohmeda 7900, incorporate this gas flow into a PEEP-generating mechanism, discussed below. Similarly, ventilator drive gas is commonly vented to the atmosphere, although it may be routed to the scavenger. The Datex-Ohmeda workstations (Avance, Aespire, and Aisys) have an adjustable needle valve in the scavenging system. Improper adjustment of this valve can result in 10 cm H2O of PEEP being applied to the patient circuit. Unintentional PEEP could result in improved lung function, but also cause hypotension or barotrauma.

Capabilities and Limitations of Anesthesia Ventilators

Anesthesia Versus Critical Care Ventilators

Historically, the anesthesiologist was limited in the type of ventilation that could be delivered to a patient. A number of reasons allowed for this limitation: 1) most surgical patients did not have pulmonary disease, 2) widespread use of muscle relaxants enabled complete control of ventilation without patient interaction, 3) the anesthesiologist was immediately available to makes changes in the ventilator settings and/or provide manually assisted ventilation, 4) use was intended for short duration, and 5) recirculation of patient gas was desirable. All these factors focused ventilator design to function only in the control mode.

In contrast, critical care ventilators became far more complex because they were used in different conditions. A trend is now apparent: anesthesia ventilators are are being manufactured to mimic the performance of their critical care counterparts while maintaining the simplicity of complete control. However, critical care ventilators offer ever-increasing complexities of flow and pressure waveforms that may not be needed, desirable, or available in anesthesia ventilators.

Ventilator Performance

Perhaps the most distinguishing characteristic of any ventilator is its performance under extremes of load—in effect, under conditions of very poor compliance. Information regarding performance of individual ventilators may not be readily available in the manufacturer’s literature and is scarcely available in the scientific literature.28,29 The American National Standards Institute (ANSI) specifies set values for compliance, resistance, and flow within a test lung as the conditions under which breathing machines for patient use should be tested to determine their performance capabilities.30 Although the operator’s manual may specify certain maximum capabilities, these numbers should be regarded as ideal figures under conditions without load. Some manufacturers specify the conditions under which their ventilator is tested, thus giving a basis for reported accuracy data.31 One study clearly demonstrates the limitations of anesthesia ventilators when subjected to increasing airway pressures.28 Minute ventilation decreased linearly for some ventilators as airway pressure increased; however, the Siemens 900D maintained its minute volume when the airway pressure was below 60 cm H2O. This might be attributed to the design of a nonrebreathing system without compression loss in the absorber.

System Compliance and Compression of Gas

As previously stated, gas compression and compliance volume losses caused by expanding hoses explain why delivered tidal volumes are frequently less than desired. Loss of tidal volume is greatest and most variable in machines that have an external ventilator connected to a circuit that includes a soda lime absorber and a humidifier. This is because the compressible volume is large, there is a greater total length of compliant breathing hose, and the change in pressure during each breath affects the gas in the entire circuit, including the bellows. The total volume of the gas that may be compressed in the circuit often exceeds 6 L. The amount lost due solely to gas compression may then be calculated; for every 10 cm H2O pressure, approximately 1% of the compressible volume is lost from the circuit. Boyle’s law (P1V1 = P2V2) explains this phenomenon. Boyle’s law can be applied such that the resultant volume (V2) is calculated by knowing the original volume (V1) and pressure (P1) and the secondary pressure (P2). For example, if compression of V1 (6000 mL) increases the pressure 10 cm H2O (1%) above atmospheric pressure (P1 = 1000 cm H2O and P2 = 1010 cm H2O), the resultant volume (V2) will be 5941 mL, or approximately 1% less. This would equal a loss of 120 mL at 20 cm H2O for a 6 L system. Next, the amount lost due to expansion of the system must be calculated by using compliance specifications from the manufacturers of the ventilator and the breathing hose. These losses typically are overcome by default of FGF, which at 3 L/min would add 100 mL to the circuit during a 2-second period of inspiration.

As the complexity of ventilators has increased, their ability to deliver the intended volume has improved. New designs with fresh gas decoupling do not contribute any fresh gas to the delivered inspiratory volume; they have low-volume, noncompliant metallic manifolds, they calculate and sequentially compensate for circuit and patient compliance and gas compression losses, and they may subtract the breathing hose volume compensation from the measured exhaled volume to report an actual exhaled volume.

Atmospheric Pressure Variations

At least one anesthesia ventilator (Siemens Servo 900B) has been tested under hyperbaric conditions (1 to 3 atm), which cause increases in gas density, resistance to flow, and dead space ventilation.32,33 Minute ventilation was found to decrease linearly as atmospheric pressure increased, but the ventilator functioned well as long as compensation was made to restore the minute ventilation.34 Different ventilators have variable outputs in flight because of lower barometric pressures, but they may be used under these conditions during military emergencies. Their performance is determined by the type of control circuit, fluidic or electronic, and the method of powering the ventilator because gas density decreases at increased altitude. Differences in the mass versus volume of gas used to control these units are responsible for the alterations in function.35 In general, effective ventilation at abnormal ambient pressure depends on providing the patient’s usual minute volume. Carbon dioxide continues to be eliminated at the usual partial pressure but is accompanied by either a smaller or greater mass of other gases.

Mode Conversion

With the appearance of pressure generator capabilities within the OR, the opportunities for conversion from flow to pressure generator systems will increase. The clinician should first record the tidal volume and frequency; peak, mean and plateau airway pressures; PEEP; and I:E ratios while in flow mode. The emphasis of the conversion is on the maintenance of plateau pressure because inspiratory, peak, and plateau pressures are merged into the square-wave airway pressure profile. Whether desired and set inspiratory pressure is absolute or whether it is a set pressure above PEEP should be noted. Leaving PEEP and frequency the same, the inspiratory time—and therefore the I:E ratio—should now be set to equal the total inspiratory time from the flow generator mode, accounting for inspiratory pause. Next, a change in modes must be initiated and the new parameters are measured; mean airway pressure should be slightly higher, considering the new airway pressure profile. Minor increases in set inspiratory pressure usually are necessary to match tidal volume.27 For convenience, some modern ventilator designs are able to apply an algorithm automatically on conversion from a volume to pressure mode, or vice versa.

Modes of Ventilation

Recently, advances in ventilator technologies have included improved microcircuit designs and applications, pressure and flow sensor enhancements, and better material design and use features that have improved the performance regardless of classification. Precision, accuracy, and reliability lie in the delivery of volume and pressure over great lengths of time and under a variety of clinical conditions. Adjunct technologies in waveform display and monitoring allow the rapid adjustment of ventilator parameters to meet dynamic intraoperative objectives.

In addition, alarms have been designed around these improved sensors and monitors, which in turn allow the delivery of safer mechanical ventilation regardless of the mode of ventilation. As such, the actual mode (method) of ventilation may be less important when endpoints of oxygenation (saturation of arterial oxygen [SaO2], pressure of arterial oxygen [PaO2]), ventilation (end-tidal carbon dioxide [ETCO2], pressure of arterial carbon dioxide [PaCO2]), tidal/minute volume, or airway pressure are managed. This may be supported by the lack of scientific literature regarding the benefits of specific modes of ventilation in the OR, except in pathophysiologic outliers.

Ventilator modes can be divided into three basic categories: 1) controlled breathing modes, 2) assisted or supported modes, and 3) spontaneous breathing without assistance or support. Division into these categories allows the user to define whether the ventilator is doing all of the work of breathing, some of the work of breathing, or none of the work of breathing, respectively. The vocabulary, however, is difficult and less than perfect—the result of historic developments, imprecise usage, and technologic advances. The use of dual modes of ventilation, especially in ventilator weaning, has added to conceptual difficulties.

Controlled Breathing Modes

In controlled breathing modes of ventilation, the patient cannot contribute any effort toward the work of breathing. Such situations commonly occur with nondepolarizing neuromuscular blocking agents, such as pancuronium. The variable to be controlled—fixed, targeted, or limited—defines the mode.

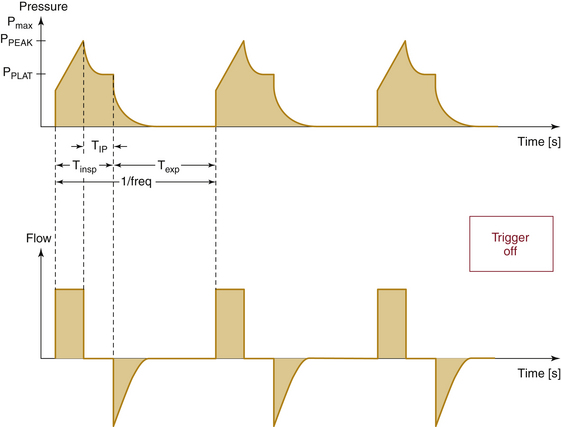

Volume-Control Ventilation

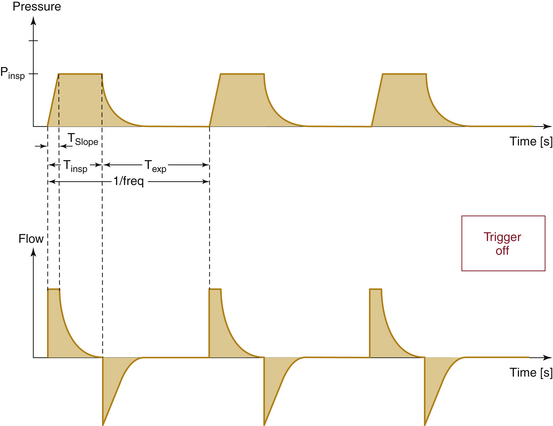

If volume is the fixed parameter, then the ventilation mode is volume-control ventilation (VCV). Modern ventilators in VCV mode require the parameters of tidal volume, respiratory rate, and I:E ratio to be set. The ventilator calculates the inspiratory time from the respiratory rate and I:E ratio, and a fixed flow for gas delivery is determined using the set tidal volume and calculated inspiratory time. Airway pressure rises linearly with time as the gas volume is pushed into the lung. The peak airway pressure is directly related to airway resistance and inversely related to lung compliance (Fig. 6-18). As such, worsening airway resistance (bronchospasm, secretions, mucus plugging) and lung compliance (fluid overload, abdominal distension) can place the patient at risk of barotrauma; therefore vigilance should be applied in the monitoring of peak airway pressure when using VCV.

Pressure-Control Ventilation

If pressure is the fixed parameter, the ventilation mode is pressure-control ventilation (PCV). In this mode, the peak airway pressure is controlled. The user must set the peak airway pressure, respiratory rate, and I:E ratio. As with VCV, the inspiratory time is calculated using the respiratory rate and I:E ratio; however, in this mode, the flow is varied to match the set peak airway pressure. This is accomplished by variable flow control. High flows are delivered at the start of inspiration, and the flow is rapidly diminished while maintaining the pressure constant. In addition, the flow tends to drop in an exponential decay over time. The tidal volume is directly proportional to lung compliance and inversely to airway resistance, so worsening airway resistance and lung compliance result in potentially inadequate oxygenation and ventilation (Fig. 6-19). An emphasis is placed on monitoring tidal volume and carbon dioxide when PCV is used because it is difficult to preset appropriate minimum and maximum volume alarms when initiating PCV.

Volume Guarantee Pressure-Control Ventilation

A recent advanced mode of PCV called volume guarantee PCV, or VG-PCV, seen in Datex-Ohmeda ventilators, allows the ventilator to change the inspiratory pressure dynamically based on the compliance of the respiratory system. In a steady-state system using PCV, a sudden improvement in pulmonary compliance would result in large tidal volumes and hyperventilation. An example of this can be seen during abdominal laparoscopic procedures, when the insufflation pressure is suddenly lost. Large tidal volumes and hyperventilation would occur until the insufflation pressure was reestablished or the anesthesiologist manually adjusted the ventilator. VG-PCV would allow the ventilator to adjust the inspiratory airway pressure dynamically over several breaths to maintain tidal volumes and ventilation parameters at a constant. Alterations in the pulmonary system that result in reduced compliance allow the ventilator to increase the set inspiratory pressure limit, which leads to an increase in the tidal volume and ventilation over several breaths; therefore the clinician must be vigilant in the adjustment of the peak pressure alarm.

Assisted and Supported Modes

In assisted and supported modes of ventilation, both the patient and the ventilator can contribute to the work of breathing. At times, the patient may be doing some or most of the work of breathing; at other times, the ventilator may contribute little to the work of breathing or the ventilator may be doing it all. These modes were developed as a solution for the pulmonary recovery of critically ill patients. As a group, these patients typically required long-standing intubation and mechanical ventilation. In the OR, these modes may allow augmentation of the patient’s breathing effort while anesthetized. When native breathing can occur, the patient’s effort is assisted, supported, or synchronized with mechanical breathing. Because the mechanical effort occurs while the patient is attempting to breathe, patient-ventilator dissynchrony is minimized, which in turn decreases coughing, bucking, and straining during surgery. The transition from effortless breathing to spontaneous breathing during an anesthetic emergency is commonly associated with risks of hypoxemia, hypercarbia, and dissynchrony. It is believed that these modes facilitate this transition by synchronizing with the patient’s effort while maintaining minimum set minute ventilation.

Assist-Control Ventilation

Assist-control ventilation (ACV) is the improvement to assisted ventilation (AV). In AV, the patient’s effort to breathe is manifested as a negative deflection in the airway pressure, and a predetermined negative pressure triggers the ventilator to deliver a set tidal volume. The user can set the trigger for small or large efforts based on the magnitude of the negative deflection. Historically, hyperventilation occurred from overtriggering that caused apnea and hypoxemia. The improvement is ACV, in which the technician sets up the ventilator the same as in VCV and the patient is able to trigger the ventilator by respiratory effort. As long as the patient triggers the ventilator more than the interval defined by the set control rate, a control breath will not be delivered. If the patient has a pause or does not breathe, controlled breaths will be delivered to the patient without being triggered, which will make this mode perform exactly like VCV. The minute ventilation is the sum of the delivered control breaths and the patient’s triggered breaths. The distinguishing feature between the two breaths (assisted vs. controlled) is the presence or lack of negative deflection in the airway pressure-time waveform, respectively.

Proportional Assisted Ventilation

Few OR ventilators use ACV, although it is not uncommon to place patients on this mode upon arrival to an ICU. For ICU patients going to the OR, VCV will substitute once the patient is anesthetized. Recently, ACV has further evolved into a new mode of ventilation called proportional assisted ventilation (PAV). The new feature, proportion, allows the tidal volume to correlate to respiratory effort, and more negative effort is rewarded with greater tidal volumes. In the past, pressure-triggering mechanisms were the only way to trigger the ventilator. Recently, these mechanisms have competed with flow-triggering mechanisms as the trigger of choice.

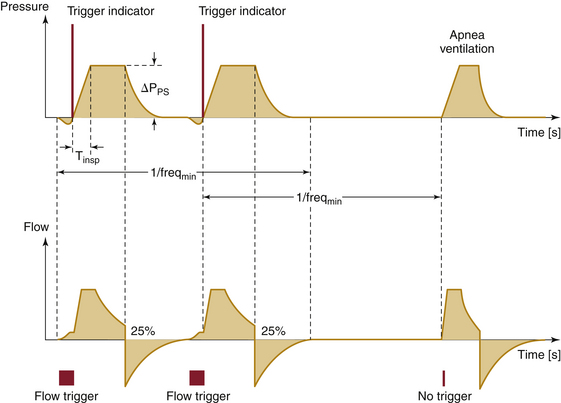

Pressure Support Ventilation

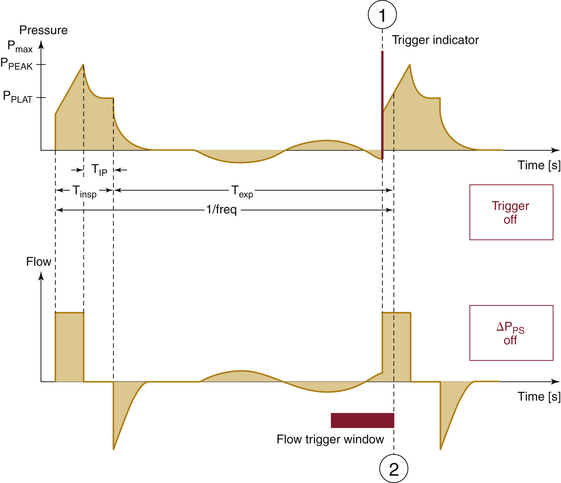

Pressure support ventilation (PSV) is the pressure equivalent of AV. In PSV mode, the clinician sets the inspiratory time, peak airway pressure to be delivered, and the trigger (Fig. 6-20). Some believe that this mode of ventilation addresses patient load issues related to compliance and resistance better than volume delivery techniques. As such, it could be considered more physiologic. Despite the lack of evidence for this claim, it has become a popular mode of ventilation in ventilator weaning in the ICU. Low-pressure PSV breaths are believed to match the resistance effects of the endotracheal tube. Use in this manner allows clinicians to equate resulting tidal volumes as the patient’s own effort and ability to overcome respiratory load. In the OR, this mode has been successfully used in adults and children to support patient breathing efforts during general anesthesia with an endotracheal tube and laryngeal mask airway. An apnea alarm and backup mode are provided for PSV mode in the OR because dynamics of the surgery and anesthetic could unexpectedly alter respiratory effort.

FIGURE 6-20 Graph of pressure and flow traces for pressure support ventilation. Shown are time-pressure (upper) and time-flow (lower) representations. Pressure or flow can be used to trigger the ventilator to cycle. The pressure trigger is indicated as a negative deflection in the pressure trace prior to inspiration; the flow trigger is indicated as inspiratory flow prior to main inspiratory pressure and flow changes. When no triggering has occurred, the ventilator will cycle without the triggering indices. (Courtesy Dräger Medical, Telford, PA.)

Intermittent Mandatory Ventilation

In intermittent mandatory ventilation (IMV), the clinican sets mandatory ventilator breaths by either volume or pressure at a defined rate and inspiratory time. Mandatory means that the patient is guaranteed the set mechanical breaths. Between breaths, however, the patient is afforded the luxury of displaying native effort. The effort can be as simple as spontaneous breathing with or without airway pressure. Also, assisted or supported breaths can be delivered between the mandatory breaths. This mode was developed for ventilator weaning and mandates a defined minute ventilation but also affords the patient the ability to exercise respiratory muscles between mandated breaths. The problem with this mode of ventilation is the risk of the patient getting a mandatory breath while not having completed a spontaneous or assisted breath. Resulting breath stacking puts the patient at risk for barotrauma.

Synchronized Intermittent Mandatory Ventilation

To avoid breath stacking, a refined mode of IMV was created called synchronized intermittent mandatory ventilation (SIMV). As with IMV, a mandatory volume or pressure, breath rate, and inspiratory time are set by the technician, and respiratory intervals are calculated for the breaths, the rate of which is known. What makes SIMV different than IMV is the ability to give a mandatory breath at the beginning or the end of the interval. This is accomplished by placing a time observation window at the beginning of each respiratory interval. This time window allows the ventilator to monitor the status of the airway for pressure or flow changes from baseline. If the pressure or flow does not exceed the set limit parameters, the mandatory breath is delivered at the beginning of the respiratory interval. If the pressure or flow exceeds the set parameters, the mandatory breath is delivered at the end of the respiratory interval. The clinician sets the pressure or flow limits and the time increment for the observation window (Fig. 6-21).

FIGURE 6-21 Graph of pressure and flow traces for synchronized intermittent mandatory ventilation. Shown are time-pressure (upper) and time-flow (lower) representations. The observational window can use pressure or flow as a monitor of airway status. (Courtesy Dräger Medical, Telford PA.)

This observation window is not a trigger as seen in ACV or PSV; it is a sensor or monitor. The rationale revolves around the volume of gas expected in the airway during the window period. Low pressure and flow changes from baseline within the window period are associated with small airway volumes, and high pressure and flow changes from baseline during the window period are associated with large volumes. The delivery of a mandatory breath at the beginning of the cycle is safe if there is no significant gas volume in the airway. Delivery of a mandatory breath when a large gas volume is already in the airway places the patient at significant risk for barotrauma. When airway volumes are predictably high, the ventilator delivers the mandatory breath at the end of the respiratory interval. Although there is still a chance that breath stacking will occur at the end of the interval, breath stacking rarely occurs in this mode.

When a patient is on SIMV mode, it is difficult to determine the ventilator mode simply by observation. Because breaths can occur at the beginning or end of a respiratory interval, consecutive mandatory breaths may appear at intervals of long, intermediate, or short duration. Consecutive breaths may be initiated in four configurations: 1) beginning and end (long interval), 2) beginning and beginning (intermediate interval), 3) end and end (intermediate interval), and 4) end and beginning (short interval). SIMV mode appears the same as VCV or PCV when the patient does not make a respiratory effort.

Spontaneous Breathing Without Assistance or Support