Electrical and Fire Safety∗

The myriad electrical and electronic devices in the modern operating room (OR) greatly improve patient care and safety. However, these devices also subject both the patient and OR personnel to increased risks. To reduce the risk of electrical shock, most ORs have electrical systems that incorporate special safety features. It is incumbent upon the anesthesiologist to have a thorough understanding of the basic principles of electricity and an appreciation of the concepts of electrical safety applicable to the OR environment.

Principles of Electricity

One basic principle of electricity is known as Ohm’s law, which is represented by the following equation, where E is electromotive force (in volts [V]), I is current (in amperes [A]), and R is resistance (in ohms [Ω]):

Ohm’s law forms the basis for the following physiologic equation:

Here, the blood pressure (BP) of the vascular system is analogous to voltage, the cardiac output (CO) is analogous to current, and the systemic vascular resistance (SVR) is analogous to the forces opposing the flow of electrons. Electrical power (p) is measured in watts. power is the product of the voltage (E) and the current (I), as defined by the formula:

The amount of electrical work done is measured in watts multiplied by a unit of time. The watt-second (a joule [J]) is a common designation for electrical energy expended in doing work. The energy produced by a defibrillator is measured in watt-seconds (joules). The kilowatt-hour is used by electrical utility companies to measure larger quantities of electrical energy.

Wattage can be thought of as a measure not only of work done but also of heat produced in any electrical circuit. Substituting Ohm’s law in the formula:

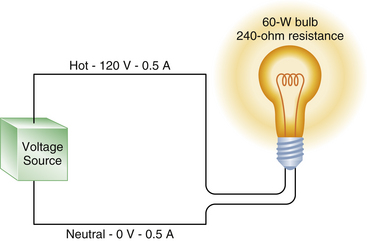

Thus, power (in watts) is equal to the square of the current I (amperage) multiplied by the resistance, R. With these formulas, it is possible to calculate the number of amperes and the resistance of a given device if the wattage and the voltage are known. For example, a 60 W lightbulb operating on a household 120 V circuit would require 0.5 A of current for operation. Rearranging the formula so that I equals p/E:

Using this in Ohm’s law (R = E/I), the resistance can be calculated to be 240 Ω:

It is obvious from the previous discussion that 1 V of electromotive force (EMF) flowing through a 1 Ω resistance will generate 1 A of current. Similarly, 1 A of current induced by 1 V of electromotive force will generate 1 W of power.

Direct and Alternating Currents

Any substance that permits the flow of electrons is called a conductor. Current is characterized by electrons flowing through a conductor. If the electron flow is always in the same direction, it is referred to as direct current (DC). However, if the electron flow reverses direction at a regular interval, it is termed alternating current (AC). Either of these types of current can be pulsed or continuous in nature.

The previous discussion of Ohm’s law is accurate when applied to DC circuits. However, when dealing with AC circuits, the situation is more complex because the flow of the current is opposed by a more complicated form of resistance, known as impedance.

Impedance

Impedance, designated by the letter Z, is defined as the sum of the forces that oppose electron movement in an AC circuit. Impedance consists of resistance (ohms [Ω]) but also takes capacitance and inductance into account. In actuality, when referring to AC circuits, Ohm’s law states that voltage equals current multiplied by impedance:

An insulator is a substance that opposes the flow of electrons. Therefore an insulator has a high impedance to electron flow, whereas a conductor has a low impedance to electron flow.

In AC circuits the capacitance and inductance can be important factors in determining the total impedance. Both capacitance and inductance are influenced by the frequency (cycles per second, or hertz [Hz]) at which the AC current reverses direction. The impedance is directly proportional to the frequency (f) times the inductance (IND):

In addition, the impedance is inversely proportional to the product of the frequency (f) and the capacitance (CAP):

As the AC current increases in frequency, the net effect of both capacitance and inductance increases. However, because impedance and capacitance are inversely related, total impedance decreases as the product of the frequency and the capacitance increases. Thus as frequency increases, impedance falls and more current is allowed to pass.

Capacitance

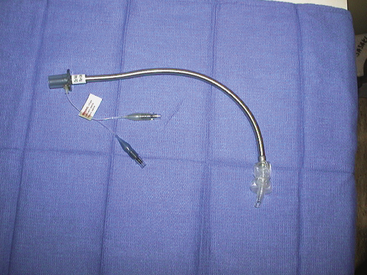

A capacitor consists of any two parallel conductors separated by an insulator (Fig. 31-1). A capacitor has the ability to store charge. Capacitance is the measure of a substance’s ability to store charge. In a DC circuit the capacitor plates are charged by a voltage source (i.e., a battery), and there is only a momentary current flow. The circuit is not completed, and no further current can flow unless a resistance is connected between the two plates and the capacitor is discharged.

FIGURE 31-1 A capacitor consists of two parallel conductors separated by an insulator. The capacitor is capable of storing charge supplied by a voltage source (V).

In contrast to DC circuits, a capacitor in an AC circuit permits current flow even when the circuit is not completed by a resistance. This is because of the nature of AC circuits, in which the current flow is constantly being reversed. Because current flow results from the movement of electrons, the capacitor plates are alternately charged—first positive and then negative, with every reversal of the AC current direction—resulting in an effective current flow as far as the remainder of the circuit is concerned, even though the circuit is not completed.

Because the effect of capacitance on impedance varies directly with the AC frequency in hertz, the greater the AC frequency, the lower the impedance. Therefore, high-frequency currents (0.5 to 2 million Hz), such as those used by electrosurgical units (ESUs), will cause a marked decrease in impedance.

Electrical devices use capacitors for various beneficial purposes. However, a phenomenon known as stray capacitance is capacitance that was not designed into the system but is incidental to the construction of the equipment. All AC-operated equipment produces stray capacitance. An ordinary power cord, for example, that consists of two insulated wires running next to each other will generate significant capacitance simply by being plugged into a 120 V circuit, even though the piece of equipment is not turned on. Another example of stray capacitance is found in electric motors. The circuit wiring in electric motors generates stray capacitance to the metal housing of the motor. The clinical importance of capacitance will be emphasized later in the chapter.

Inductance

Whenever electrons flow in a wire, a magnetic field is induced around the wire. If the wire is coiled repeatedly around an iron core, as in a transformer, the magnetic field can be very strong. Inductance is a property of AC circuits in which an opposing EMF can be electromagnetically generated in the circuit. The net effect of inductance is to increase impedance. Because the effect of inductance on impedance also depends on AC frequency, increases in frequency will increase the total impedance. Therefore the total impedance of a coil will be much greater than its simple resistance.

Electrical Shock Hazards

Alternating and Direct Currents

Whenever an individual contacts an external source of electricity, an electric shock is possible. An electric current can stimulate skeletal muscle cells to contract and thus can be used therapeutically in devices such as pacemakers or defibrillators. However, casual contact with an electrical current, whether AC or DC, can lead to injury or death. Although it takes approximately three times as much DC as AC to cause ventricular fibrillation, this by no means renders DC harmless. Devices such as an automobile battery or a DC defibrillator can be sources of direct current shocks.

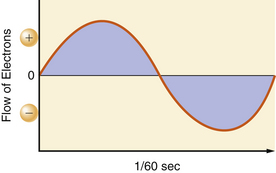

In the United States, utility companies supply energy in the form of alternating currents of 120 V at a frequency of 60 Hz. The 120 V of EMF and 1 A of current are the effective voltage and amperage in an AC circuit. This is also referred to as root-mean-square (RMS). It takes 1.414 A of peak amperage in the sinusoidal curve to give an effective amperage of 1 A. Similarly, it takes 170 V (120 × 1.414) at the peak of the AC curve to get an effective voltage of 120 V. The 60 Hz refers to the number of times in 1 second that the current reverses its direction of flow. Both the voltage and current waveforms form a sinusoidal pattern (Fig. 31-2).

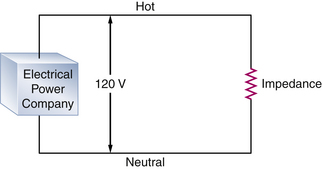

To have the completed circuit necessary for current flow, a closed loop must exist, and a voltage source must drive the current through the impedance. If current is to flow in the electrical circuit, there has to be a voltage differential, or a drop in the driving pressure across the impedance. According to Ohm’s law, if the resistance is held constant, the greater the current flow, the larger the voltage drop must be.

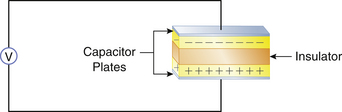

The power company attempts to maintain the line voltage constant at 120 V. Therefore by Ohm’s law, the current flow is inversely proportional to the impedance. A typical power cord consists of two conductors: one, designated as hot, carries the current to the impedance; the other is neutral, and it returns the current to the source. The potential difference between the two is effectively 120 V (Fig. 31-3). The amount of current flowing through a given device is frequently referred to as the load. The load of the circuit depends on the impedance. A very high impedance circuit allows only a small current to flow and thus has a small load. A very low impedance circuit will draw a large current and is said to carry a large load. A short circuit occurs when there is a zero impedance load with a very high current flow.1

FIGURE 31-3 A typical alternating current (AC) circuit. A potential difference of 120 V exists between the hot and neutral sides of the circuit. The current flows through a resistance, which in AC circuits is more accurately referred to as impedance, and then returns to the electrical power company.

Source of Shocks

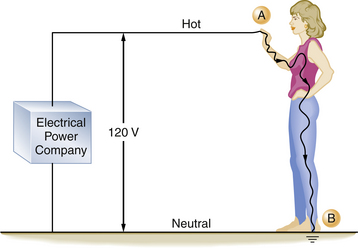

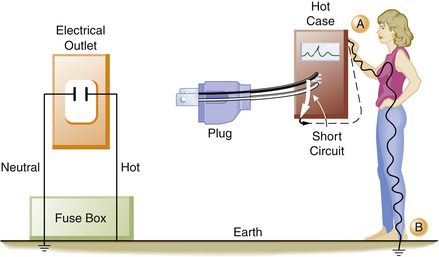

Electrical accidents or shocks occur when a person becomes part of, or completes, an electrical circuit. To receive a shock, a person must contact the electrical circuit at two points, and there must be a voltage source that causes the current to flow through the individual (Fig. 31-4).

FIGURE 31-4 An individual can complete an electrical circuit and receive a shock. If the person is standing on the ground (point B), by coming in contact with the hot side of the circuit (point A), the contact point and the ground provide the two contact points necessary for a completed circuit. The severity of the shock received depends on the individual’s skin resistance.

FIGURE 31-5 A 60 W lightbulb has an internal resistance of 240 Ω and draws a 0.5 A current. The voltage drop in the circuit is from 120 V in the hot wire to zero in the neutral wire, but the current is 0.5 A in both the hot and neutral wires.

When an individual comes in contact with a source of electricity, injury occurs in one of two ways. First, the electrical current can disrupt the normal electrical function of cells. Depending on its magnitude, the current can contract muscles, alter brain function, paralyze respiration, or disrupt normal heart function, leading to ventricular fibrillation. The second mechanism involves the dissipation of electrical energy throughout the body’s tissues. An electrical current passing through any resistant substance raises the temperature of that substance. If enough thermal energy is released, the temperature will rise sufficiently to produce a burn. Accidents involving household currents usually do not result in severe burns. However, in accidents involving very high voltages (i.e., power transmission lines), severe burns are common.

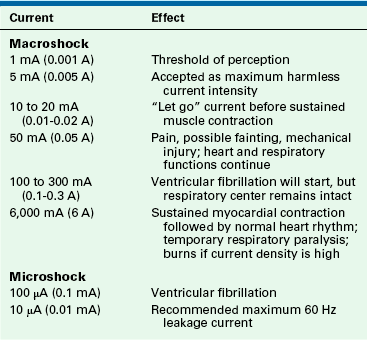

The severity of an electrical shock is determined by the amount of current (amperes) and the duration of the current flow. For the purposes of this discussion, electrical shocks are divided into two categories: macroshock refers to large amounts of current flowing through a person, which can cause harm or death; microshock refers to very small amounts of current. Concern for injury with microshock applies only to the electrically susceptible patient, an individual who has an external conduit that is in direct contact with the heart; this can be a pacing wire or a saline-filled catheter, such as a central venous or pulmonary artery catheter. In the case of the electrically susceptible patient, even minute amounts of current (microshocks) can cause ventricular fibrillation.

Table 31-1 shows the effects typically produced by various currents following a 1-second contact with a 60 Hz current. When an individual contacts a 120-V household current, the severity of the shock will depend on his or her skin resistance, the duration of the contact, and the current density. Skin resistance can vary from a few thousand to 1 million Ω. If a person with a skin resistance of 1000 Ω contacts a 120 V circuit, he or she would receive 120 mA of current, which would probably be lethal. However, if that same person’s skin resistance is 100,000 Ω, the current flow would be 1.2 mA, which would barely be perceptible.

The longer an individual is in contact with the electrical source, the more dire the consequences because more energy will be released, and more tissue will be damaged. Also, there will be a greater chance of ventricular fibrillation from excitation of the heart during the vulnerable period of the electrocardiogram (ECG) cycle.

Current density is a way of expressing the amount of current applied per unit area of tissue. The diffusion of current in the body tends to be in all directions. The greater the current or the smaller the area to which it is applied, the higher the current density. In relation to the heart, a current of 100 mA (100,000 μA) is generally required to produce ventricular fibrillation when applied to the surface of the body. However, only 100 μA (0.1 mA) is required to produce ventricular fibrillation when that minute current is applied directly to the myocardium through an instrument with a very small contact area, such as a pacing wire electrode. In this case, the current density is a thousandfold greater when applied directly to the heart; therefore only  of the energy is required to cause ventricular fibrillation. An electrically susceptible patient can be electrocuted with currents well below 1 mA, which is the threshold of perception for humans.

of the energy is required to cause ventricular fibrillation. An electrically susceptible patient can be electrocuted with currents well below 1 mA, which is the threshold of perception for humans.

The frequency at which the current reverses is also an important factor in determining the amount of current an individual can safely contact. Utility companies in the United States produce electricity at a frequency of 60 Hz, because higher frequencies cause greater power loss through transmission lines, and lower frequencies cause a detectable flicker from light sources.2 The “let go” current is defined as that current above which sustained muscular contraction occurs and at which an individual would be unable to let go of an energized wire. The let-go current for 60 Hz AC power is 10 to 20 mA,1,3,4 whereas at a frequency of 1 million Hz, up to 3 A (3000 mA) is generally considered safe. It should be noted that very high frequency currents do not excite contractile tissue; consequently, they do not cause cardiac dysrhythmias.

It can be seen that Ohm’s law governs the flow of electricity. For a completed circuit to exist, a closed loop must exist with a driving pressure to force a current through a resistance, just as in the cardiovascular system, in which BP must drive the cardiac output through the peripheral resistance. Figure 31-5 illustrates that a hot wire carrying a 120 V pressure through the resistance of a 60 W lightbulb produces a current flow of 0.5 A. The voltage in the neutral wire is approximately zero volts, whereas the current in the neutral wire remains at 0.5 A. This correlates with our cardiovascular analogy, in which a mean BP decrease of 80 mm Hg between the aortic root and the right atrium forces a cardiac output of 6 L/min through a systemic vascular resistance of 13.3 resistance units. However, the flow—in this case, the cardiac output, or in the case of the electrical model, the current—is still the same everywhere in the circuit. That is, the cardiac output on the arterial side is the same as the cardiac output on the venous side.

Grounding

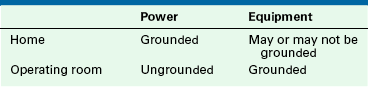

To fully understand electrical shock hazards and their prevention, the clinician must have a thorough knowledge of the concepts of grounding. These concepts of grounding probably constitute the most confusing aspects of electrical safety, because the same term is used to describe several different principles. In electrical terminology, the term grounding is applied to two separate concepts. The first is the grounding of electrical power, and the second is the grounding of electrical equipment. Thus the concepts that power can be grounded or ungrounded and that power can supply electrical devices that are themselves grounded or ungrounded are not mutually exclusive. It is vital to understand this point as the basis of electrical safety. Whereas electrical power is grounded in the home, it is usually ungrounded in the OR (Table 31-2). In the home, electrical equipment may be grounded or ungrounded, but it should always be grounded in the OR.

Electrical Power: Grounded

Electrical utilities universally provide power that is grounded (by convention, the earth-ground potential is zero, and all voltages represent a difference between potentials); that is, one of the wires supplying the power to a home is intentionally connected to the earth. The utility companies do this as a safety measure to prevent electrical charges from building up in their wiring during electrical storms. This also prevents the very high voltages used in transmitting power by the utility from entering the home in the event of an equipment failure in their high-voltage system.

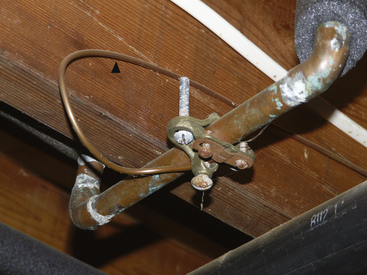

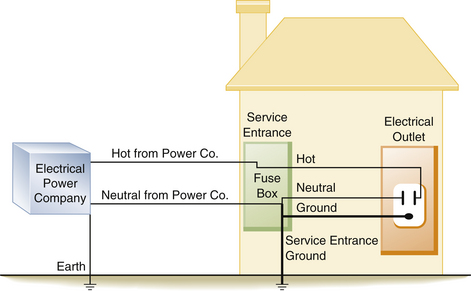

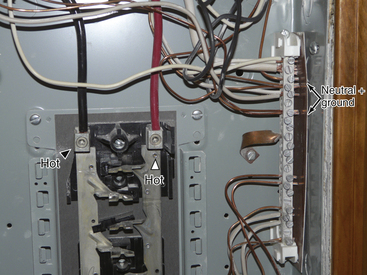

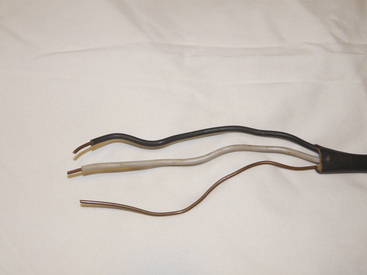

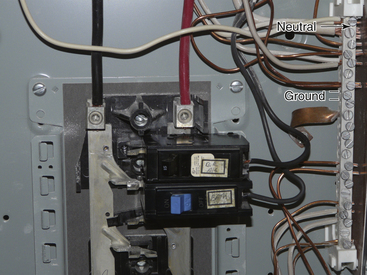

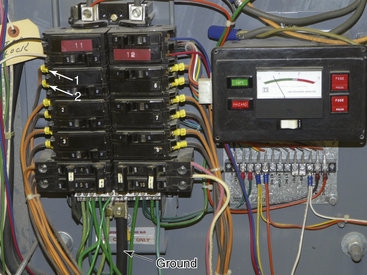

The power enters the typical home via two wires attached to the main fuse box or circuit breaker box at the service entrance. The “hot” (electrified) wire supplies power to the hot distribution strip. The neutral wire is connected to the neutral distribution strip and to a service entrance ground (i.e., a pipe buried in the earth; Fig. 31-6). From the fuse box, three wires leave to supply the electrical outlets in the house. In the United States, the hot wire is color-coded black and carries a 120 V above-ground potential. The second wire is the neutral wire color-coded white; the third wire is the ground wire, which is either color-coded green or is uninsulated (bare wire). The ground and the neutral wires are attached at the same point in the circuit breaker box and are also connected to a cold-water pipe (Figs. 31-7 and 31-8). Thus, this grounded power system is also referred to as a neutral grounded power system. The black wire is not connected to the ground, because this would create a short circuit. The black wire is attached to the hot distribution strip (i.e., 120 V above ground) on which the circuit breakers or fuses are located. From here, numerous branch circuits supply electrical power to the outlets in the house. Each branch circuit is protected by a circuit breaker or fuse that limits current to a specific maximum amperage. Most electrical circuits in the house are 15 or 20 A circuits. These typically supply power to the electrical outlets and lights in the house. Several higher amperage circuits are also provided for certain devices, such as electric stoves or clothes dryers. These devices are powered by 240 V circuits, which can draw from 30 to 50 A of current. The circuit breaker or fuse will interrupt the flow of current on the hot side of the line in the event of a short circuit, or if the demand placed on that circuit is too high. For example, a 15 A branch circuit is capable of supporting 1800 W of power.

FIGURE 31-6 In a neutral grounded power system, the electric company supplies two lines to the typical home. The neutral wire is connected to ground by the power company and is also connected to a service entrance ground when it enters the fuse box or breaker panel. Both the neutral and ground wires are connected together in the supply box at the neutral bus bar, which is also attached to the service entrance ground.

FIGURE 31-7 Inside a breaker panel with the circuit breakers removed. The arrowheads indicate the hot wires energizing the strips where the circuit breakers are located. The arrows point to the neutral bus bar, where the neutral and ground wires are connected.

Therefore if two 1500 W hair dryers were simultaneously plugged into one outlet, the load would be too great for a 15 A circuit, and the circuit breaker would open (trip), or the fuse would melt. This is designed to prevent the supply wires in the circuit from melting and starting a fire. The amperage of the circuit breaker on the branch circuit is determined by the thickness of the wire that it supplies. If a 20 A breaker is used with wire rated for only 15 A, the wire could melt and start a fire before the circuit breaker would trip. It is important to note that a 15 A circuit breaker does not protect an individual from lethal shocks; the 15 A of current that would trip the circuit breaker far exceeds the 100 to 200 mA that will produce ventricular fibrillation.

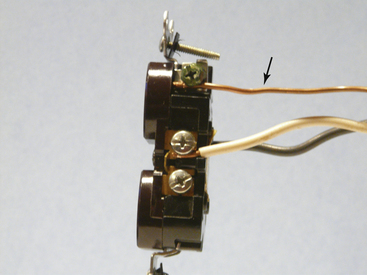

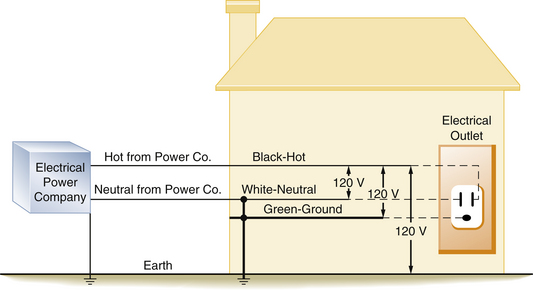

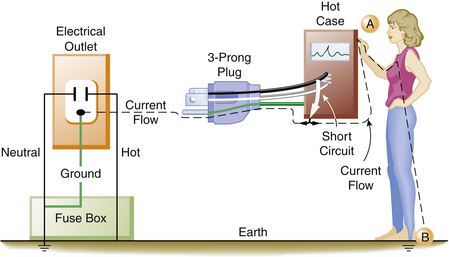

The wires that leave the circuit breaker supply the electrical outlets and lighting for the rest of the house. In older homes the electrical cable consists of two wires, a hot and a neutral, which supply power to the electrical outlets (Fig. 31-9). In newer homes, a third wire has been added to the electrical cable (Fig. 31-10). This third wire is either green or uninsulated (bare) and serves as a ground wire for the power receptacle (Fig. 31-11). On one end, the ground wire is attached to the receptacle (Fig. 31-12); on the other, it is connected to the neutral distribution strip in the circuit breaker box along with the neutral (white) wires (Fig. 31-13).

FIGURE 31-9 An older style electrical outlet. Only two wires are present, a hot and a neutral. There is no ground wire.

FIGURE 31-10 Modern electrical cable in which a third wire, or ground, has been added. Wires from top to bottom are hot, neutral, and ground.

FIGURE 31-11 Modern electrical outlet in which the ground wire is present. The arrowhead points to the part of the receptacle where the ground wire connects.

FIGURE 31-12 Detail of modern electrical power receptacle. The arrow points to the ground wire (bare wire), which is attached to the green grounding screw on the power receptacle.

FIGURE 31-13 The ground wires (bare wires) from the power outlet are run to the neutral bus bar, where they are connected with the neutral wires (white wires; arrow).

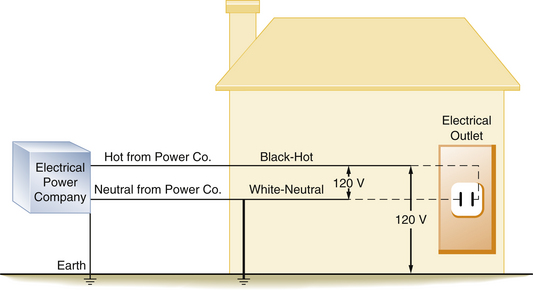

It should be realized that in both the old and new situations, the power is grounded. That is, a 120 V potential exists between the hot (black) and the neutral (white) wire and between the hot wire and the ground. In this case, the ground is the earth (Fig. 31-14). In modern home construction, a 120 V potential difference exists between the hot and the neutral wire, and a difference of 120 V is found between the equipment ground wire, which is the third wire, and also between the hot wire and the earth (Fig. 31-15).

FIGURE 31-14 Diagram of a house with older style wiring that does not contain a ground wire. A 120 V potential difference exists between the hot and the neutral wires and between the hot wire and the earth.

FIGURE 31-15 Diagram of a house with modern wiring in which a third wire, or ground, has been added. The 120 V potential difference exists between the hot and neutral wires, the hot and the ground wires, and the hot wire and the earth.

A 60 W lightbulb can be used as an example to further illustrate this point. Normally, the hot and neutral wires are connected to the two wires of the lightbulb socket, and throwing the switch will illuminate the bulb (Fig. 31-16). Similarly, if the hot wire is connected to one side of the bulb socket, and the other wire from the lightbulb is connected to the equipment ground wire, the bulb will still illuminate. If there is no equipment ground wire, the bulb will still light if the second wire is connected to any grounded metallic object, such as a water pipe or a faucet. This illustrates the fact that the 120 V potential difference exists not only between the hot and the neutral wires but also between the hot wire and any grounded object. Thus in a grounded power system, the current will flow between the hot wire and any conductor with an earth ground.

FIGURE 31-16 A simple lightbulb circuit. The hot (black) and neutral (white) wires are connected with the corresponding wires from the lightbulb fixture.

As previously stated, current flow requires a closed loop with a source of voltage. For an individual to receive an electric shock, he or she must contact the loop at two points. Because we may be standing either on the ground or in contact with an object that is referenced to the ground, only one additional contact point is necessary to complete the circuit and thereby receive an electrical shock. This is an unfortunate and inherently dangerous consequence of grounded power systems. Modern wiring systems have added the third wire, the equipment ground wire, as a safety measure to reduce the severity of a potential electrical shock. This is accomplished by providing an alternate, low-resistance pathway through which the current can flow to the ground.

Over time the insulation covering the wires may deteriorate. It is then possible for a bare, hot wire to contact the metal case or frame of an electrical device. The case would then become energized and would create a shock hazard to anyone coming in contact with it. Figure 31-17 illustrates a typical short circuit, in which the individual has come in contact with the hot (electrified) case of an instrument. This illustrates the type of wiring found in older homes: there is no ground wire in the electrical outlet, nor is the electrical apparatus equipped with a ground wire. Here, the individual completes the circuit and receives a severe shock. Figure 31-18 illustrates a similar example, except that now the equipment ground wire is part of the electrical distribution system. In this example, the equipment ground wire provides a pathway of low impedance through which the current can travel; therefore most of the current would travel through the ground wire. In this case, the person may get a shock, but it is unlikely to be fatal.

FIGURE 31-17 When a faulty piece of equipment without an equipment ground wire is plugged into an electrical outlet that also does not contain a ground wire, the case of the instrument will become hot. An individual touching the hot case (point A) will receive a shock because he or she is standing on the earth (point B), completing the circuit. The current (dashed line) will flow from the instrument through the individual touching the hot case.

FIGURE 31-18 When a faulty piece of equipment with an equipment ground wire is properly connected to an electrical outlet with a grounding connection, the current (dashed line) will preferentially flow down the low-resistance ground wire. An individual touching the case (point A) while standing on the ground (point B) will still complete the circuit; however, only a small part of the current will go through the individual.

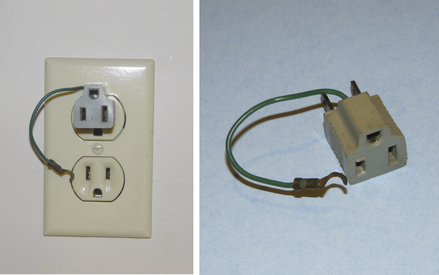

The electrical power supplied to homes is always grounded. A 120 V potential always exists between the hot conductor and the ground or earth. The third or equipment ground wire used in modern electrical wiring systems does not normally have current flowing through it. In the event of a short circuit, an electrical device with a three-prong plug (i.e., a ground wire connected to its case) will conduct the majority of the short-circuited or “fault” current through the ground wire and away from the individual. This provides a significant safety benefit to someone accidentally contacting the defective device. If a large enough fault current exists, the ground wire also will provide a means to complete the short circuit back to the circuit breaker or fuse, and this will either melt the fuse or trip the circuit breaker. Thus, in a grounded power system, it is possible to have either grounded or ungrounded equipment, depending on when the wiring was installed and whether the electrical device is equipped with a three-prong plug that contains a ground wire. Obviously, attempts to bypass the safety system of the equipment ground should be avoided. Devices such as a “cheater plug” (Fig. 31-19) should never be used because they defeat the safety feature of the equipment ground wire.

Electrical Power: Ungrounded

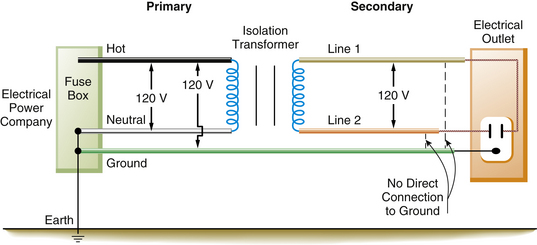

Numerous electronic devices, together with power cords and puddles of saline solution on the floor, make the OR an electrically hazardous environment for both patients and personnel. Bruner and colleagues5 found that 40% of electrical accidents in hospitals occurred in the OR. The complexity of electrical equipment in the modern OR demands that electrical safety be a factor of paramount importance. To provide an extra measure of safety from macroshock, the power supplied to most ORs is ungrounded. In this ungrounded power system, the current is isolated from ground potential. The 120 V potential difference exists only between the two wires of the isolated power system (IPS), but no circuit exists between the ground and either of the isolated power lines.

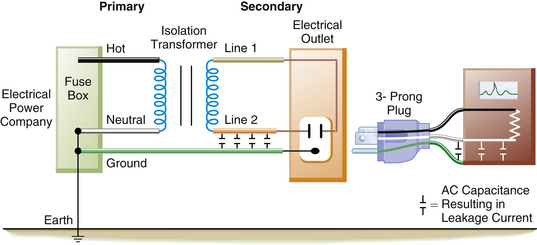

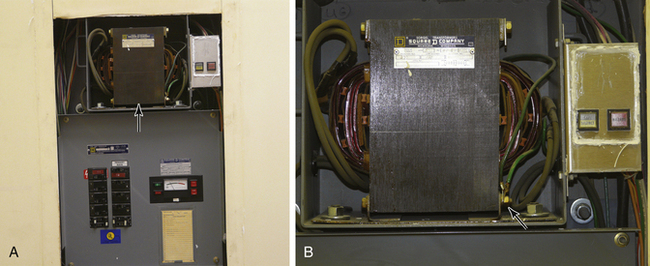

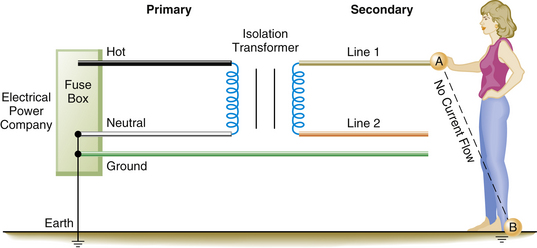

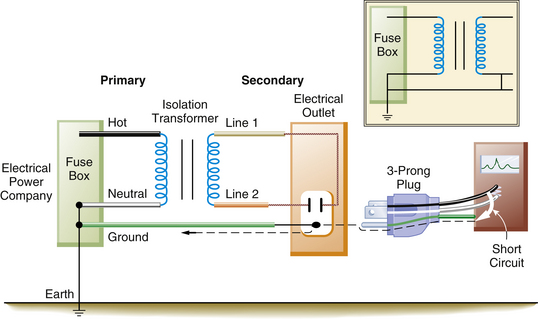

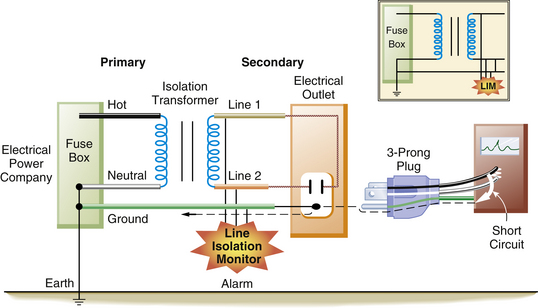

Supplying ungrounded power to the OR requires the use of an isolation transformer (Fig. 31-20). This device uses electromagnetic induction to induce a current in the ungrounded or secondary winding of the transformer from energy supplied to the primary winding. No direct electrical connection exists between the power supplied by the utility company on the primary side and the power induced by the transformer on the ungrounded, or secondary, side. Thus, the power supplied to the OR is isolated from ground (Fig. 31-21). Because the 120 V potential exists only between the two wires of the isolated circuit, neither wire is hot or neutral with reference to ground; in this case, they are simply referred to as line 1 and line 2 (Fig. 31-22). Using the example of the lightbulb, if the two wires of the bulb socket are connected to the two wires of the IPS, the bulb will illuminate. However, if one of the wires is connected to one side of the isolated power, and the other wire is connected to the ground, the light will not illuminate. If the wires of the IPS are connected, the short circuit will trip the circuit breaker. In comparing the two systems, standard grounded power has a direct connection to ground, whereas the isolated system imposes a very high impedance to any current flow to ground. The added safety of this system can be seen in Figure 31-23. In this case, a person has come in contact with one side of the IPS (point A). Because standing on the ground (point B) does not constitute a part of the isolated circuit, the individual does not complete the loop and will not receive a shock. This is because the ground is part of the primary circuit, and the person is contacting only one side of the isolated secondary circuit. The person does not complete either circuit; that is, the person does not have two contact points; therefore this situation does not pose an electric shock hazard. Of course, if the person contacts both lines of the IPS, an unlikely event, he or she would receive a shock.

FIGURE 31-20 A, Isolated power panel showing circuit breakers, line isolation monitor, and isolation transformer (arrow). B, Detail of an isolation transformer with the attached warning lights. The arrow points to ground wire connection on the primary side of the transformer. Note that no similar connection exists on the secondary side of the transformer.

FIGURE 31-21 In the operating room, the isolation transformer converts the grounded power on the primary side to an ungrounded power system on the secondary side of the transformer. A 120 V potential difference exists between line 1 and line 2. There is no direct connection from the power on the secondary side to ground. The equipment ground wire, however, is still present.

FIGURE 31-22 Detail of the inside of a circuit breaker box in an isolated power system. The bottom arrow points to ground (green) wires meeting at the common ground terminal. Arrows 1 and 2 indicate lines 1 and 2 (orange and brown) from the isolated power circuit breaker. Neither line 1 nor line 2 is connected to the same terminals as the ground wires. This is in marked contrast to Figure 31-13, where the neutral and ground wires are attached at the same point.

FIGURE 31-23 A safety feature of the isolated power system (IPS). An individual in contact with one side of the IPS (point A) and standing on the ground (point B) will not receive a shock. In this instance, the individual is not contacting the circuit at two points and thus is not completing the circuit. Point A is part of the IPS, and point B is part of the primary or grounded side of the circuit.

If a faulty electrical appliance with an intact equipment ground wire is plugged into a standard household outlet, and the home wiring has a properly connected ground wire, the amount of electrical current that will flow through a person is considerably less than what will flow through the low-resistance ground wire. Here, an individual would be fairly well protected from a serious shock. However, if that ground wire were broken, the person might receive a lethal shock. No shock would occur if the same faulty piece of equipment were plugged into the IPS, even if the equipment ground wire were broken. Thus the IPS provides a significant amount of protection from macroshock. Another feature of the IPS is that the faulty piece of equipment, even though it may be partially short-circuited, will not usually trip the circuit breaker. This is an important feature, because the faulty piece of equipment may be part of a life-support system for a patient. It is important to note that even though the power is isolated from ground, the case or frame of all electrical equipment is still connected to an equipment ground. The third wire, the equipment ground wire, is a necessary component of any electrical safety program.

Figure 31-24 illustrates a scenario involving a faulty piece of equipment connected to the IPS. This does not represent a hazard; it merely converts the isolated power back to a grounded power system as exists outside the OR. In fact, a second fault is necessary to create a hazard.

FIGURE 31-24 A faulty piece of equipment plugged into the isolated power system (IPS) does not present a shock hazard. It merely converts the IPS into a grounded power system. The inset illustrates that the IPS is now identical to the grounded power system. The dashed line indicates current flow in the ground wire.

The previous discussion assumes that the IPS is perfectly isolated from ground. Actually, perfect isolation is impossible to achieve; all AC-operated power systems and electrical devices manifest some degree of capacitance. As previously discussed, electrical power cords, wires, and electrical motors exhibit capacitive coupling to the ground wire and metal conduits, and they leak small amounts of current to ground (Fig. 31-25). This so-called leakage current partially ungrounds the IPS; this does not usually amount to more than a few milliamperes in an OR, so a person coming in contact with one side of the IPS would receive only a very small shock (1 to 2 mA). Although this amount of current would be perceptible, it would not be dangerous.

Line Isolation Monitor

The line isolation monitor (LIM) is a device that continuously monitors the integrity of an IPS. If a faulty piece of equipment is connected to the IPS, this will, in effect, change the system back to a conventional grounded system. Also, the faulty piece of equipment will continue to function normally. Therefore it is essential that a warning system be in place to alert personnel that the power is no longer ungrounded. The LIM continuously monitors the isolated power to ensure that it is indeed isolated from ground, and the device has a meter that displays a continuous indication of the integrity of the system (Fig. 31-26). The LIM is actually measuring the impedance to ground of each side of the IPS. As previously discussed, with perfect isolation, impedance would be infinitely high, and no current would flow in the event of a first-fault situation (Z = E/I; if I = 0, then Z = ∞). Because all AC wiring and all AC-operated electrical devices have some capacitance, small leakage currents are present that partially degrade the isolation of the system. The meter of the LIM will indicate (in milliamperes) the total amount of leakage in the system resulting from capacitance, electrical wiring, and any devices plugged into the IPS.

FIGURE 31-26 The meter of the line isolation monitor (LIM) is calibrated in milliamperes. If the isolation of the power system is degraded such that more than 2 mA of current (5 mA in newer systems) could flow, the hazard light will illuminate, and a warning buzzer will sound. Note the button for testing the hazard warning system. A, Older LIM that will trigger an alarm at 2 mA. B, Newer LIM that will trigger an alarm at 5 mA. C, The LIM alarm is triggered, and the red hazard stripe is illuminated; the number on the right shows 9.9 mA of potential current flow.

The reading on the LIM does not mean that current is actually flowing; rather it indicates how much current would flow in the event of a first fault. The LIM is set to alarm at 2 or 5 mA, depending on the age and brand of the system. Once this preset limit is exceeded, visual and audible alarms are triggered to indicate that the isolation from ground has been degraded beyond a predetermined limit (Fig. 31-27). This does not necessarily mean that a hazardous situation exists; rather it shows that the system is no longer totally isolated from ground; a second fault is required to create a dangerous situation. For example, if the LIM were set to alarm at 2 mA, using Ohm’s law, the impedance for either side of the IPS would be 60,000 Ω:

FIGURE 31-27 When a faulty piece of equipment is plugged into the isolated power system, it will markedly decrease the impedance from line 1 or line 2 to ground. This will be detected by the line isolation monitor, which will sound an alarm.

Therefore if either side of the IPS had less than 60,000 Ω impedance to ground, the LIM would trigger an alarm. This might occur in two situations. In the first, a faulty piece of equipment is plugged into the IPS. In this case, a true fault to ground exists from one line to the ground. Now the system would be converted to the equivalent of a grounded power system. This faulty piece of equipment should be removed and serviced as soon as possible, although it could still be used safely if it were essential for the care of the patient. It should be remembered, however, that continuing to use this faulty piece of equipment would create the potential for a serious electrical shock. This would occur if a second faulty piece of equipment were simultaneously connected to the IPS.

The second situation involves connecting many perfectly normal pieces of equipment to the IPS. Although each piece of equipment has only a small amount of leakage current, if the total leakage exceeds 2 mA, the LIM will trigger an alarm. Assume that 30 electrical devices are present in the OR, and each has 100 μA of leakage current; the total (30 × 100 μA) would be 3 mA. The impedance to ground would still be 40,000 Ω (120/0.003), and the LIM alarm would sound in this instance, because the 2 mA set point was violated. However, the system is still safe and represents a state significantly different from that in the first situation. For this reason, the newer LIMs are set to alarm at 5 mA instead of 2 mA.

The newest LIMs are referred to as third-generation monitors. The first-generation monitor, or static LIM, was unable to detect balanced faults (i.e., a situation in which there are equal faults to ground from both lines 1 and 2). The second-generation monitor, or dynamic LIM, did not have this problem but could interfere with physiologic monitoring. Both of these monitors would trigger an alarm at 2 mA, which led to annoying “false” alarms. The third-generation LIM corrects the problems of its predecessors and has the alarm threshold set at 5 mA.6 Proper functioning of the LIM depends on having both equipment ground wires intact and its own connection to ground. First- and second-generation LIMs could not detect the loss of the LIM ground connection. The third-generation LIM can detect this loss of ground to the monitor. In this case, the LIM alarm would sound, and the red hazard light would illuminate, but the LIM meter would read zero; this condition will alert the staff that the LIM needs to be repaired. In any event, the LIM still cannot detect broken equipment ground wires. An example of the third-generation LIM is the Iso-Gard, made by Square D (Monroe, NC).

The equipment ground wire is again an important part of the safety system. If this wire is broken, a faulty piece of equipment plugged into an outlet would operate normally, but the LIM would not alarm. A second fault could therefore cause a shock without any alarm from the LIM. Also, in the event of a second fault, the equipment ground wire provides a low-resistance path to ground for most of the fault current (see Fig. 31-24). The LIM will only be able to register leakage currents from pieces of equipment that are connected to the IPS and that have intact ground wires.

If the LIM alarm is triggered, the first thing to do is to check the gauge to determine whether it is a true fault; the other possibility is that too many pieces of electrical equipment have been plugged in, and the 2 mA limit has been exceeded. If the gauge is between 2 and 5 mA, it is probable that too much electrical equipment has been plugged in. If the gauge reads over 5 mA, most likely a faulty piece of equipment is present. The next step is to identify the faulty equipment, which is done by unplugging each piece of equipment until the alarm ceases. If the faulty piece of equipment is not of a critical nature, it should be removed from the OR. If it is a vital piece of life-support equipment, it can be safely used. (Note: if a critical piece of life-support equipment, such as the cardiopulmonary bypass machine, is the suspected cause of the alarm, do not disconnect it until it is no longer needed.) It must be remembered that the protection of the IPS and the LIM is no longer operative. Therefore if possible, no other electrical equipment should be connected during the remainder of the case, or at least until the faulty piece of equipment can be safely removed.

Ground Fault Circuit Interrupter

The ground fault circuit interrupter (GFCI, or occasionally GFI) is another popular device used to prevent individuals from receiving an electrical shock in a grounded power system. Electrical codes for most new construction require that a GFCI circuit be present in potentially hazardous (e.g., wet) areas such as bathrooms, kitchens, or outdoors. The GFCI may be installed as an individual power outlet (Fig. 31-28), or a special circuit breaker may be installed to which all the individual protected outlets are connected at a single point. The special GFCI circuit breaker is located in the main breaker box and can be distinguished by its red test button (Fig. 31-29). As Figure 31-5 demonstrates, the current flowing in both the hot and neutral wires is usually equal. The GFCI monitors both sides of the circuit for the equality of current flow; if a difference is detected, the power is immediately interrupted. If an individual should contact a faulty piece of equipment such that current flowed through the person, an imbalance between the two sides of the circuit would be created, which would be detected by the GFCI. Because the GFCI can detect very small current differences (in the range of 5 mA), the GFCI will open the circuit within a few milliseconds, thereby interrupting the current flow before a significant shock occurs. Thus the GFCI provides a high level of protection at a very modest cost. If the OR has a GFCI that tripped, an attempt should first be made to reset it by pushing the reset button; this is because a surge may have caused the GFCI to trip. If it cannot be reset, the equipment must be removed from service and checked by the biomedical engineering staff. It is essential that when GFCIs are used in an OR, only one outlet should be protected by each GFCI. They should never be “daisy-chained” such that one GFCI protects multiple outlets.

FIGURE 31-28 A ground fault circuit interrupter electrical outlet with integrated test (black) and reset (red) buttons.

FIGURE 31-29 Special ground fault circuit interrupter circuit breaker. Note the distinguishing red test button.

The disadvantage of using a GFCI in the OR is that it interrupts the power without warning. A defective piece of equipment could no longer be used, which could be a problem if it were essential for life support; whereas if the same faulty piece of equipment were plugged into an IPS, the LIM would alarm, but the equipment could still be used.

Double Insulation

One instance in which it is acceptable for a piece of equipment to have only a two-prong and not a three-prong plug is when the instrument has what is termed double insulation. These instruments have two layers of insulation and usually have a plastic exterior. Double insulation is found in many home power tools and is seen in hospital equipment such as infusion pumps. Double-insulated equipment is permissible in the OR with IPSs; however, if water or saline should get inside the unit, it could present a hazard because the double insulation is bypassed. This is even more serious if the OR has no isolated power or GFCIs.7

Microshock

As previously discussed, macroshock involves relatively large amounts of current applied to the surface of the body. The current is conducted through all the tissues in proportion to their conductivity and area in a plane perpendicular to the current. Consequently, the “density” of the current (amperes per meter squared) that reaches the heart is considerably less than what is applied to the body surface. However, an electrically susceptible patient—one who has a direct external connection to the heart, such as through a central venous pressure catheter or transvenous cardiac pacing wires—may be at risk from very small currents; this is called microshock.8 The catheter orifice or electrical wire with a very small surface area in contact with the heart produces a relatively large current density at the heart.9 Stated another way, even very small amounts of current applied directly to the myocardium will cause ventricular fibrillation. Microshock is a particularly difficult problem because of the insidious nature of the hazard.

In the electrically susceptible patient, ventricular fibrillation can be produced by a current that is below the threshold of human perception. The exact amount of current necessary to cause ventricular fibrillation in this type of patient is unknown. Whalen and colleagues10 were able to produce fibrillation with 20 μA of current applied directly to the myocardium of dogs. Raftery and colleagues11 produced fibrillation with 80 μA of current in some patients. Hull12 used data obtained by Watson and collagues13 to show that 50% of patients would fibrillate at currents of 200 μA. Because 1000 μA (1 mA) is generally regarded as the threshold of human perception with 60 Hz AC, the electrically susceptible patient can be electrocuted with one tenth of the normally perceptible currents. This is not only of academic interest but also of practical concern, because many cases of ventricular fibrillation from microshock have been reported.14-18

The stray capacitance that is part of any AC-powered electrical instrument may result in significant amounts of charge buildup on the case of the instrument. If an individual simultaneously touches the case of an instrument where this has occurred in the electrically susceptible patient, he or she may unknowingly cause a discharge to the patient that results in ventricular fibrillation. Once again, the equipment ground wire constitutes the major source of protection against microshock for the electrically susceptible patient. In this case, the equipment ground wire provides a low-resistance path by which most of the leakage current is dissipated instead of stored as a charge.

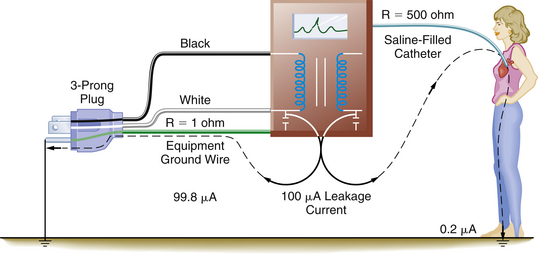

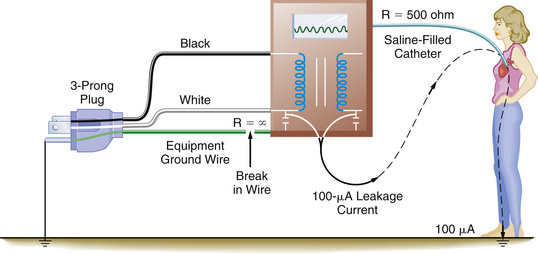

Figure 31-30 illustrates a situation involving a patient with a saline-filled catheter in the heart with a resistance of about 500 Ω. The ground wire with a resistance of 1 Ω is connected to the instrument case, and a leakage current of 100 μA will divide according to the relative resistances of the two paths: in this case, 99.8 μA will flow through the equipment ground wire, and only 0.2 μA will flow through the fluid-filled catheter. This extremely small current does not endanger the patient. However, if the equipment ground wire were broken, the electrically susceptible patient would be at great risk, because all 100 μA of leakage current could flow through the catheter and cause ventricular fibrillation (Fig. 31-31). Currently, electronic equipment is permitted 100 μA of leakage current.

FIGURE 31-30 The electrically susceptible patient is protected from microshock by the presence of an intact equipment ground wire. The equipment ground wire provides a low-impedance path in which the majority of the leakage current (dashed lines) can flow. R, resistance.

FIGURE 31-31 A broken equipment ground wire results in a significant hazard to the electrically susceptible patient. In this case, the entire leakage current can be conducted to the heart and may result in ventricular fibrillation. R, resistance.

Modern patient monitors incorporate another mechanism to reduce the risk of microshock for electrically susceptible patients.19 This mechanism involves electrically isolating all direct patient connections from the power supply of the monitor by placing a very high impedance between the patient and any device. This limits the amount of internal leakage through the patient connection to a very small value; the standard currently is less than 10 μA. For instance, the output of an ECG monitor’s power supply is electrically isolated from the patient by placing a very high impedance between the monitor and the patient’s ECG leads.20 Isolation techniques are designed to inhibit hazardous electrical pathways between the patient and the monitor while allowing the passage of the physiologic signal.

An intact equipment ground wire is probably the most important factor in preventing microshock. There are, however, other things that the anesthesiologist can do to reduce the incidence of microshock, such as to never simultaneously touch an electrical device and a saline-filled central catheter or external pacing wires. When handling a central catheter or pacing wires, it is best to insulate oneself by wearing rubber gloves. Also, never let any external current source, such as a nerve stimulator, come into contact with the catheter or wires. Finally, be alert to potential sources of energy that can be transmitted to the patient; even stray radiofrequency current from the ESU (cautery) can, under the right conditions, be a source of microshock.21 It must be remembered that the LIM is not designed to provide protection from microshock. The microampere currents involved in microshock are far below the LIM threshold of protection. In addition, the LIM does not register the leakage of individual monitors but rather indicates the status of the total system. The LIM reading indicates the total amount of leakage current resulting from the entire capacitance of the system. This is the amount of current that would flow to ground in the event of a first-fault situation.

The essence of electrical safety is a thorough understanding of all the principles of grounding; the objective of preventing injury is to make it difficult for electrical current to pass through people. For this reason, both the patient and the anesthesiologist should be isolated from ground as much as possible. That is, their resistance to current flow should be as high as is technologically feasible.

In the inherently unsafe electrical environment of an OR, several measures can be taken to help protect against contacting hazardous current flows. First, the grounded power provided by the utility company can be converted to ungrounded power by means of an isolation transformer. The LIM will continuously monitor the status of this isolation from ground and will issue a warning when the isolation of the power (from ground) has been lost, in the event that a defective piece of equipment is plugged into one of the isolated circuit outlets. In addition, the shock that an individual could receive from a faulty piece of equipment is determined by the capacitance of the system and is limited to a few milliamperes. Because all equipment plugged into the IPS has an equipment ground wire attached to the case of the instrument, this equipment ground wire will provide an alternative low-resistance pathway to enable potentially dangerous currents to flow to ground. Thus the patient and the anesthesiologist should be as insulated from ground as much as possible, and all electrical equipment should be grounded.

The equipment ground wire serves three functions. First, it provides a low-resistance path for fault currents to reduce the risk of macroshock. Second, it dissipates leakage currents that are potentially harmful to the electrically susceptible patient. Third, it provides information to the LIM on the status of the ungrounded power system. If the equipment ground wire is broken, a significant factor in the prevention of electrical shock is lost. Additionally, the IPS will appear safer than it actually is, because the LIM is unable to detect broken equipment ground wires.

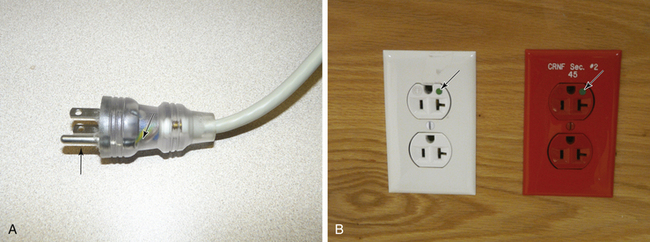

Because power cords, plugs, and receptacles are subjected to greater abuse in the hospital than in the home, the Underwriters Laboratories (Melville, NY) has issued a strict specification for special “hospital grade” plugs and receptacles (Fig. 31-32). The plugs and receptacles that conform to this specification are marked by a green dot.22 The hospital-grade plug is one that can be visually inspected or easily disassembled to ensure the integrity of the ground wire connection; molded opaque plugs are not acceptable. Edwards23 reported that of 3000 non–hospital-grade receptacles installed in a new hospital building, 1800 (60%) were found to be defective after 3 years. When 2000 of the non–hospital-grade receptacles were replaced with hospital-grade receptacles, no failures occurred after 18 months of use.

FIGURE 31-32 A, A hospital-grade plug that can be visually inspected. The arrow points to the equipment ground wire, whose integrity can be readily verified. Note that the prong for the ground wire (arrow) is longer than the hot or neutral prong, so that it is the first to enter the receptacle. B, The arrows point to the green dot, denoting a hospital-grade power outlet. The red outlet on the right is connected to the emergency power (generator) system.

Electrosurgery

On that fateful October day in 1926, when Dr. Harvey W. Cushing first used an electrosurgical (ESU) machine invented by Professor William T. Bovie to resect a brain tumor, the course of modern surgery and anesthesia was forever altered.24 The ubiquitous use of electrosurgery attests to the success of Professor Bovie’s invention. However, this technology was not adopted without a cost. The widespread use of electrocautery has, at the very least, hastened the elimination of explosive anesthetic agents from the OR. In addition, as every anesthesiologist is aware, few things in the OR are immune to interference from the “Bovie.” The high-frequency electrical energy generated by the ESU interferes with everything from the ECG signal to cardiac output computers, pulse oximeters, and even implanted cardiac pacemakers.25

The ESU operates by generating currents of a very high frequency—in the radiofrequency range, anywhere from 500,000 to 1 million Hz. Heat is generated whenever a current passes through a resistance, and the amount of heat produced (H) is proportional to the square of the current and inversely proportional to the area through which the current passes (H = I2/A).26 By concentrating the energy at the tip of the “Bovie pencil,” the surgeon can produce either a cut or a coagulation at any given spot. This very-high-frequency current behaves differently from the standard 60 Hz AC current and can pass directly across the precordium without causing ventricular fibrillation.26 This is because high-frequency currents have a low tissue penetration and do not excite contractile cells.

Although the ESU is used safely hundreds of thousands of times each year, there is evidence that under certain circumstances it has been the cause of ventricular fibrillation.27-30 The mechanism is thought to be low frequency (50 to 60 Hz) “stray current” generated when the ESU is activated. Current in the 50 to 60 Hz range can cause ventricular fibrillation. These cases have been associated with use of the coagulation mode, when the surgeon is using the device near the heart, and when the patient has a conductor in the heart such as a central venous pressure or pulmonary artery catheter. However, the exact mechanism has not been proven.

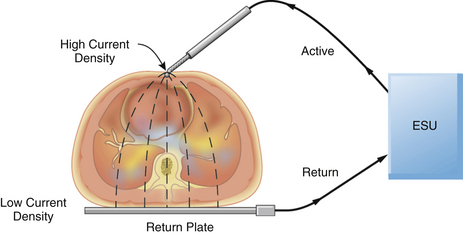

The large amount of energy generated by the ESU can pose other problems to the operator and the patient. Cushing became aware of one such problem. He wrote, “Once the operator received a shock which passed through a metal retractor to his arm and out by a wire from his headlight, which was unpleasant to say the least.”31 The ESU cannot be safely operated unless the energy is properly routed from the ESU through the patient and back to the unit. Ideally, the current generated by the active electrode is concentrated at the ESU tip, constituting a very small surface area. This energy has a high current density and is able to generate enough heat to produce a therapeutic cut or coagulation. The energy then passes through the patient to a dispersive electrode of large surface area that returns the energy safely to the ESU (Fig. 31-33).

FIGURE 31-33 A properly applied electrosurgical unit (ESU) return plate. The current density at the return plate is low, resulting in no danger to the patient.

One unfortunate quirk in terminology concerns the return (dispersive) plate of the ESU. This plate, often incorrectly referred to as a ground plate, is actually a dispersive electrode of large surface area that safely returns the generated energy to the ESU via a low current density pathway. When inquiring whether the dispersive electrode has been attached to the patient, OR personnel frequently ask, “Is the patient grounded?” Because the aim of electrical safety is to isolate the patient from ground, this expression is worse than erroneous; it can lead to confusion. Because the area of the return plate is large, the current density is low; therefore, no harmful heat is generated, and no tissue destruction occurs. In a properly functioning system, the only tissue effect is at the site of the active electrode held by the surgeon.

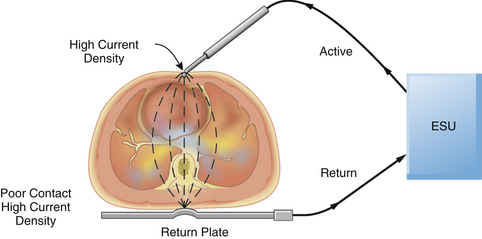

Problems can arise if the electrosurgical return plate is improperly applied to the patient or if the cord connecting the return plate to the ESU is damaged or broken. In these instances, the high-frequency current generated by the ESU will seek an alternate return pathway. Anything attached to the patient, such as ECG leads or a temperature probe, can provide this alternate return pathway. The current density at the ECG pad will be considerably higher than normal, because its surface area is much less than that of the ESU return plate; this may result in a serious burn at this alternate return site. Similarly, a burn may occur at the site of the ESU return plate if it is not properly applied to the patient, or if it becomes partially dislodged during the operation (Fig. 31-34). This is not merely a theoretical possibility but is evidenced by the numerous case reports involving patients who have received ESU burns.32-37

FIGURE 31-34 An improperly applied electrosurgical unit (ESU) return plate. Poor contact with the return plate results in a high current density and a possible burn to the patient.

The original ESUs were manufactured with the power supply connected directly to ground by the equipment ground wire. These devices made it extremely easy for ESU current to return by alternate pathways. The ESU would continue to operate normally even without the return plate connected to the patient. In most modern ESUs, the power supply is isolated from ground to protect the patient from burns.38 It was hoped that by isolating the return pathway from ground, the only route for current flow would be via the return electrode. Theoretically, this would eliminate alternate return pathways and greatly reduce the incidence of burns. However, Mitchell39 found two situations in which the current could return via alternate pathways, even with the isolated ESU circuit. If the return plate were left either on top of an uninsulated ESU cabinet or in contact with the bottom of the OR table, the ESU could operate fairly normally, and the current would return via alternate pathways. It should be recalled that the impedance is inversely proportional to the capacitance times the current frequency. The ESU operates at 500,000 to more than 1 million Hz, which greatly enhances the effect of capacitive coupling and causes a marked reduction in impedance. Therefore even with isolated ESUs, the decrease in impedance allows the current to return to the ESU by alternate pathways. In addition, the isolated ESU does not protect the patient from burns if the return electrode does not make proper contact with the patient. Although the isolated ESU does provide additional patient safety, it is by no means foolproof protection against the patient receiving a burn.

Preventing patient burns from the ESU is the responsibility of all professional staff in the OR. Not only the circulating nurse but also the surgeon and the anesthesiologist must be aware of proper techniques and be vigilant to potential problems. The most important factor is the proper application of the return plate; it is essential that the return plate has the appropriate amount of electrolyte gel and an intact return wire. Reusable return plates must be properly cleaned after each use, and disposable plates must be checked to ensure that the electrolyte has not dried out during storage. In addition, it is prudent to place the return plate as close as possible to the site of the operation; ECG pads should be placed as far from the site of the operation as is feasible. In addition, OR personnel must be alert to the potential for pools of flammable “prep” solutions, such as alcohol and acetone, to ignite when the ESU is used. If the ESU must be used on a patient with a demand pacemaker, the return electrode should be located below the thorax; in addition, preparations for treating potential dysrhythmias should be available, including a defibrillator, an external pacemaker, and a magnet to convert the pacemaker to a fixed rate. It is best to keep the pacemaker out of the path between the surgical site and the dispersal plate.

The ESU has also caused other problems in patients with pacemakers, including reprogramming and microshock.40,41 If the surgeon requests higher than normal power settings on the ESU, this should alert both the circulating nurse and the anesthesiologist to a potential problem. The return plate and cable must be immediately inspected to ensure that it is functioning and properly positioned. If this does not correct the problem, the return plate should be replaced.42,43 If the problem remains, the entire ESU should be taken out of service. Finally, an ESU that is dropped or damaged must be removed immediately from the OR and thoroughly tested by a qualified biomedical engineer. Following these simple safety steps will prevent most patient burns from the ESU.

The previous discussion concerned only unipolar ESUs; a second type of ESU, in which the current passes only between the two blades of a pair of forceps, is also used. This type of device is referred to as a bipolar ESU. Because the active and return electrodes are the two blades of the forceps, it is not necessary to attach another dispersive electrode to the patient, unless a unipolar ESU is also being used. The bipolar ESU generates considerably less power than the unipolar device and is mainly used for ophthalmic and neurologic surgery.

In 1980 Mirowski and colleagues44 reported the first human implantation of a device to treat intractable ventricular tachydysrhythmias. This device, known as the automatic implantable cardioverter-defibrillator (AICD), is capable of sensing ventricular tachycardia and ventricular fibrillation and automatically defibrillating the patient. Since 1980, thousands of patients have received AICD implants.45,46 Because some of these patients may come in for noncardiac surgery, it is important that the anesthesiologist be aware of potential problems.47 The use of a unipolar ESU may cause electrical interference that could be interpreted by the AICD as a ventricular tachydysrhythmia. This would trigger a defibrillation pulse to be delivered to the patient and would likely cause an actual episode of ventricular tachycardia or ventricular fibrillation. The patient with an AICD is also at risk for ventricular fibrillation during electroconvulsive therapy.47 In both cases, the AICD should be disabled by placing a magnet over the device or by use of a specific protocol to shut it off; the device can be reactivated by reversing the process. In any event, it is best to consult with someone experienced with the device before starting surgery. Also, an external defibrillator and a noninvasive pacemaker should be in the OR whenever a patient with an AICD is anesthetized.

Electrical safety in the OR is a matter of combining common sense with some basic principles of electricity. Once OR personnel understand the importance of safe electrical practices, they are able to develop a heightened awareness to potential problems. All electrical equipment must undergo routine maintenance, service, and inspection to ensure that it conforms to designated electrical safety standards. Records of these test results must be kept for future inspection, because human error can easily compound electrical hazards. Starmer and colleagues48 cited one case concerning a newly constructed laboratory, where the ground wire was not attached to a receptacle. In another study Albisser and colleagues49 found a 14% (198 of 1424) incidence of improperly or incorrectly wired outlets.

Potentially hazardous situations should be recognized and corrected before they become a problem. For instance, electrical power cords are frequently placed on the floor where they can be crushed by various carts or the anesthesia machine. These cords could be located overhead or placed in an area of low traffic flow. Multiple-plug extension boxes should not be left on the floor where they can come in contact with electrolyte solutions. These could easily be mounted on a cart or on the anesthesia machine. Pieces of equipment that have been damaged or have obvious defects in the power cord must not be used until they have been properly repaired. If everyone is aware of what constitutes a potential hazard, dangerous situations can be prevented with minimal effort.

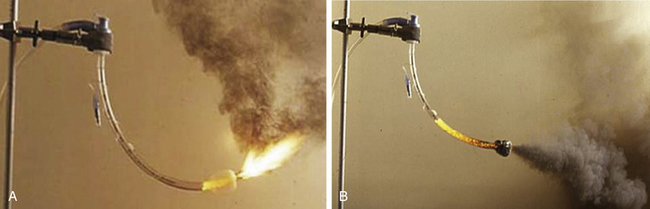

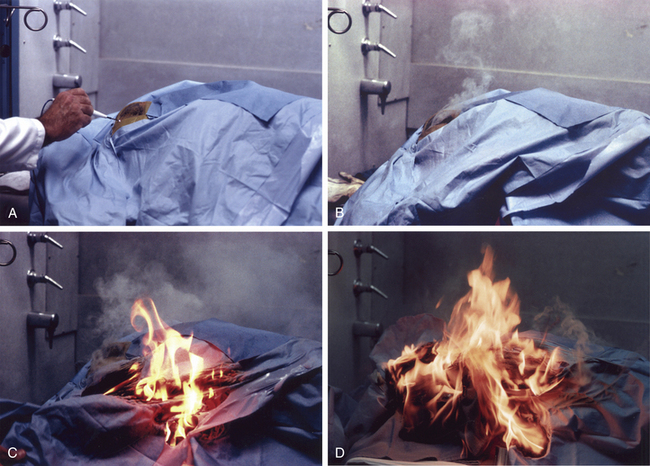

Sparks generated by the ESU may provide the ignition source for a fire with resulting burns to the patient and OR personnel. This is a particular risk when the ESU is used in an oxygen-enriched environment as may be present in the patient’s airway or in close proximity to the patient’s face. The administration of high-flow nasal oxygen to a sedated patient during procedures on the face and eye is particularly hazardous. Most plastics that would not burn in room air, such as tracheal tubes and components of the anesthetic breathing system, will ignite in the presence of oxygen or nitrous oxide. Tenting of the drapes to allow dispersion of any accumulated oxygen or its dilution by room air or use of a circle anesthesia breathing system with minimal to no leak of gases around the anesthesia mask will decrease the risk of ignition from a spark generated by a nearby ESU.

Conductive Flooring

In the past, conductive flooring was mandated for ORs where flammable anesthetic agents were being administered to minimize the buildup of static charges that could cause a flammable anesthetic agent to ignite. The standards have now been changed to eliminate the necessity for conductive flooring in anesthetizing areas where flammable agents are no longer used.

Environmental Hazards

A number of potential electrical hazards in the OR are of concern to the anesthesiologist. The potential for electrical shock is present not only for the patient but also for OR personnel. In addition, cables and power cords to electrical equipment and monitoring devices can become hazardous through wear and misuse. Finally, all OR personnel should have a plan that outlines what to do in the event of a power failure.

Today’s OR is populated with literally dozens of pieces of electrical equipment. It is not uncommon to have numerous power cords lying on the floor, where they are vulnerable to damage. If the insulation on the power cable becomes damaged, it is fairly easy for the hot wire to come in contact with a piece of metal equipment. If the OR does not have isolated power, that piece of equipment can become energized and pose a potential electrical shock hazard.50 Having isolated power minimizes the risk to the patient and OR personnel. Clearly, getting electrical power cords off the floor is desirable. This can be accomplished by having electrical outlets in the ceiling or by having ceiling-mounted articulated arms that contain electrical outlets. Also, the use of multiple-outlet extension boxes that sit on the floor can be hazardous and should be avoided. In addition, these can become contaminated with fluids, which could easily trip the circuit breaker. In one case, it apparently tripped the main circuit breaker for the entire OR and resulted in a loss of all electrical power except for the overhead lights.51

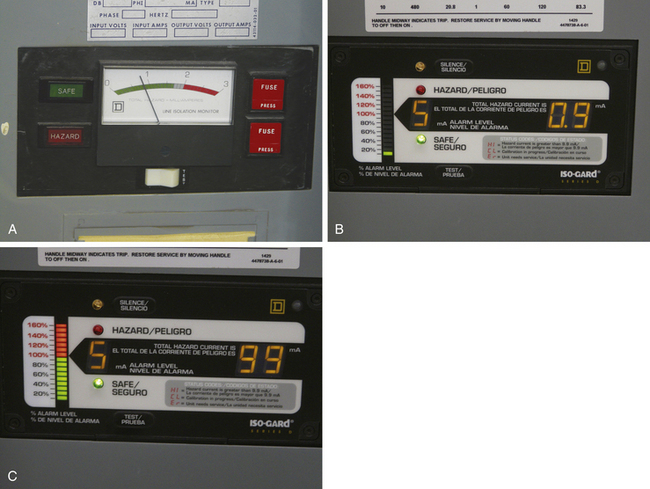

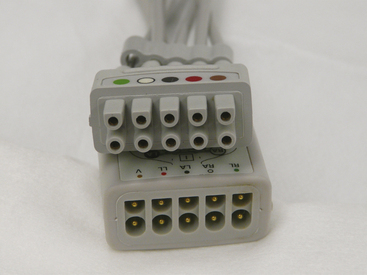

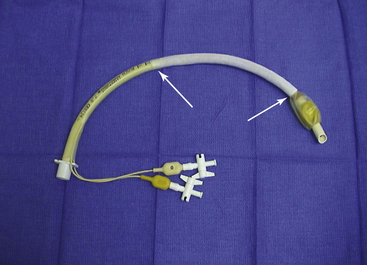

Modern monitoring devices have many safety features incorporated into them. Virtually all of them have isolated the patient input from the power supply of the device. This is frequently done with optocoupler isolation circuits, an important feature that was lacking in the original ECG monitors. In the early days, patients could actually become part of the electrical circuit of the monitor. Relatively few problems have been experienced with patients and monitoring devices since the advent of isolated inputs. However, between 1985 and 1994, the Food and Drug Administration (FDA) received approximately 24 reports in which infants and children had received an electrical shock, including five children who died by electrocution.52,53 These electrical accidents occurred because the electrode lead wires from either an ECG monitor or an apnea monitor were plugged directly into a 120 V electrical outlet instead of the appropriate patient cable. In 1997, the FDA issued a new performance standard for electrode lead wires and patient cables that requires exposed male connector pins from the electrode lead wires to be eliminated. Therefore, the lead wires must have female connections, and the connector pins must be housed in a protected patient cable (Fig. 31-35). This effectively eliminates the possibility of the patient being connected directly to an AC source, because no connector pins on the lead wires are exposed.

FIGURE 31-35 The current standard for patient lead wires (top) requires a female connector. The patient cable (bottom) has shielded connector pins that the lead wires plug into.

All health care facilities are required to have a source of emergency power. This generally consists of one or more electrical generators configured to start up automatically and provide power to the facility within 10 seconds after detecting a loss of power from the utility company. The facility is required to test these generators on a regular basis. However, in the past, not all health care facilities tested them under actual load. There are numerous anecdotal reports of generators not functioning properly during an actual power failure. If the generators are not tested under actual load, it is possible that many years will pass before a real power outage puts a severe demand on the generator. If the facility has several generators and one of them fails, the increased demand on the others may be enough to cause them all to fail in rapid succession. Under the current National Fire Protection Association (NFPA) 99 standards, hospitals must test their emergency power supply systems (generators) under connected load once a month for at least 30 minutes. If the generator is oversized for the application and cannot be loaded to at least 30% of its rating, it must be load-banked and run for a total of 2 hours every year. A fairly recent requirement is for emergency power supply systems to be tested once every 3 years for 4 continuous hours, with a recommendation that this be performed during peak usage of the system.54,55

Although all hospitals are required to have emergency generators to power essential equipment in the event of a power failure, they do not function in every circumstance. If there is a loss of power from the electrical utility, this is detected by a relay switch, which causes a series of events to activate the transfer of the power generation to the backup system. This usually happens seamlessly. However, if the transfer switch or the generator fails, there will be no back-up electricity.

Another cause of partial or total power failure has to do with construction mishaps. As hospitals frequently remodel, add new wings, or upgrade existing facilities, there is always a chance that the power will be accidentally interrupted, such as from a worker tripping a GFCI or a relay failure that causes a power transfer to a nonworking generator.56,57 Because the electrical utility is still supplying power, the generators may not be activated.

It is vitally important that each OR have a contingency plan for a power failure. There should be a supply of battery-operated light sources available in each OR. A laryngoscope can serve as a readily available source of light until flashlights and such can be located. The overhead lights in the OR should also be connected to some sort of battery-operated lighting system. Most anesthesia machines have a back-up battery that will last 30 to 60 minutes. If the power failure lasts longer than that, the anesthesiologist must plan how to continue the anesthetic. The newer electronic machines may be more problematic than older traditional machines, because they may have electronic gas or vaporization systems. The department should have a supply of battery-powered monitors, but it is unlikely there will be enough for every OR. Syringe pumps typically have a battery, and BP can be taken with a manual sphygmomanometer. Because many ORs use automated drug-dispensing systems, these devices will not work without power and a communication link to the hospital information system. In reality, the back-up generators will usually supply power in the event of an emergency. However, there are many circumstances in which a hospital could experience partial or total power loss. And although the cost of preparing for these contingencies is relatively small, the benefits can be invaluable in an emergency.

Electromagnetic Interference

Rapid advances in technology have led to an explosion in the number of wireless communication devices in the marketplace. These devices include cellular telephones, cordless telephones, walkie-talkies, and wireless Internet access devices. All of these devices have something in common: they emit electromagnetic interference (EMI). The problem with this most commonly manifests when traveling on airplanes: most airlines require that these devices be turned off when the plane is taking off or landing, and in some cases during the entire flight, because of a concern that the EMI emitted by these devices may interfere with the plane’s navigation and communication equipment.

In recent years, the number of people who own these devices has increased exponentially. Indeed, in some hospitals, such devices form a vital link in both the regular and emergency communication systems. It is not uncommon for physicians, nurses, paramedics, and other personnel to have their own cellular telephones. In addition, patients and visitors may also have cellular telephones and other types of communication devices. Hospital maintenance and security personnel frequently have walkie-talkie–type radios, and some hospitals have even instituted an in-house cellular telephone network that augments or replaces the paging system. However, concern has been raised that the EMI emitted by these devices may interfere with implanted pacemakers and various types of monitoring devices and ventilators in critical care areas.58 One patient death was reported when a ventilator malfunctioned secondary to EMI.59