Chapter 35 Powders and granules

Introduction

A powder may be defined as a solid material in a finely divided state. Granules are powders agglomerated to produce larger free-flowing particles. Powders and granules can be used to prepare other formulations, such as solutions, suspensions and tablets. A powdered drug on its own can be a dosage form for taking orally (called a simple powder), when they are usually mixed with water first, or for external application as a dusting powder. Alternatively the drug may be blended with other ingredients (called a compound powder).

Powders for internal use

Powders for oral administration will comprise the active ingredients with excipients such as diluents, sweeteners and dispersing agents. These may be presented as undivided powders (bulk powders) or divided powders (individually wrapped doses).

Magnesium Trisilicate Powder Compound BP (see Example 35.4) and Compound Kaolin Powder BP are examples of bulk powders for internal use. Proprietary powders and granules include Dioralyte®, Electrolade® (both oral rehydration salts), Normacol® (sterculia) and Fybogel® (ispaghula husk). Individually wrapped powders tend not to be official formulae (see Examples 35.1 and 35.2).

Example 35.1

Hyoscine hydrobromide 300 micrograms. Mitte 4 powders.

Label ‘One to be given 30 minutes before the journey’.

Action and uses. Antimuscarinic drug used in the prevention of motion sickness.

Calculation and method of preparation. Calculate for five powders. Use lactose as the diluent, each powder to weigh 120 mg.

Hyoscine hydrobromide (5 × 300) = 1500 micrograms = 1.5 mg

Lactose (5 × 120 mg) to 600 mg

The minimum weighable quantity (using a Class B balance) is 100 mg.

Step A

Make a 1 in 10 dilution of hyoscine hydrobromide with lactose:

Mix by doubling-up and remove 100 mg (triturate A).

100 mg of triturate A contains 100/1000 × 100 = 10 mg hyoscine hydrobromide.

Example 35.2

Send 18 ibuprofen powders for a child of 3 years to provide 20 mg/kg daily. Take 1 twice daily (child’s weight is 14 kg).

The dose required = 20 × 14 = 280 mg daily.

Therefore each powder to contain 140 mg.

| For 1 powder | For 20 powders (2 excess) | |

| Ibuprofen | 140 mg | 2.8 g |

Bulk powders

Supplying as an undivided powder is useful for non-potent, bulky drugs with a large dose, e.g. antacids, or when the dry powder is more stable than its liquid-containing counterpart. A bulk powder can be supplied to the patient although this is rarely seen nowadays because the dosage form is inconvenient to carry and there are possible inaccuracies in measuring the dose. Some liquid mixtures may be prepared in the pharmacy from a bulk powder by the addition of a specific volume of water, e.g. Magnesium Trisilicate Mixture BP. This reduces transport and packaging costs.

Individually wrapped powders

Individually wrapped powders are used to supply some potent drugs, where accuracy of dose is important. Extemporaneously produced powders are wrapped separately in paper. They are convenient dosage forms for children’s doses of drugs which are not commercially available at the strength required, such as levothyroxine (thyroxine) or ibuprofen (see Example 35.2). Sealed sachets of powders are available commercially, e.g. Paramax (paracetamol and metoclopramide) and oral rehydration salts. They are mixed with water prior to taking and are useful for patients who have difficulty swallowing or where rapid absorption of the drug is required.

Granules for internal use

Some preparations are supplied to the pharmacy as granules, for reconstitution immediately before dispensing, e.g. antibiotic suspensions. This protects drugs which are susceptible to hydrolysis or other degradation in the presence of water until the time of dispensing in order to give an adequate shelf life (see Ch. 31).

Particle size

The particle size of a powder is described using standard descriptions given in the British Pharmacopoeia (BP). These refer to either the standardized sieve size that they are capable of passing through in a specified time under shaking, or to the microscopically determined particle size. Thus powders for oral use would normally be a ‘moderately fine’ or a ‘fine’ powder. The former is able to pass through a sieve of nominal mesh aperture 355 μm and the latter one of 180 μm. Comminution is the process of particle size reduction. On a small scale, this can be achieved using a mortar and pestle when it is usually called trituration. This is a common first step in extemporaneous dispensing, after which the powder should be passed through the appropriate sieve before weighing.

Mixing the powder

Ingredients of powders should be mixed thoroughly, using the technique of ‘doubling-up’ (sometimes called geometric dilution) to ensure an even distribution. This process involves starting with the ingredient which has the smallest bulk. In Example 35.1 this is hyoscine hydrobromide. The other ingredient(s) are added progressively in approximately equal parts by volume. In this way the amount in the mortar is approximately doubled at each addition. Mixing in between additions continues until all the ingredients are incorporated. The powder can then be packed.

Preparing individually wrapped powders

The minimum weight of an individually wrapped powder is 120 mg. Dilution of a drug with a diluent, usually lactose, is often necessary to produce this weight.

Occasionally manufactured tablets or capsules may be used to prepare oral powders (see Example 35.2). This involves either crushing the tablet in a mortar and pestle, or emptying the contents of the capsule and adding a suitable diluent. Lactose is the most commonly used diluent because it is colourless, odourless, soluble, is generally harmless and has good flow properties. Some patients may be unable to tolerate lactose and a suitable inert alternative diluent, for instance light kaolin, would then be used.

Powder calculations

Quantities should be calculated to allow for loss of powder during manipulation. It is usual to allow for at least one extra powder. If the total amount of active ingredient required is less than the minimum weighable quantity, dilutions will be necessary. In this process, also called trituration, the minimum quantity of the active ingredient(s) is weighed and diluted, over several steps if necessary, in order to obtain the dose(s) required. Example 35.1 illustrates the process where two dilution steps are required (see also Ch. 26).

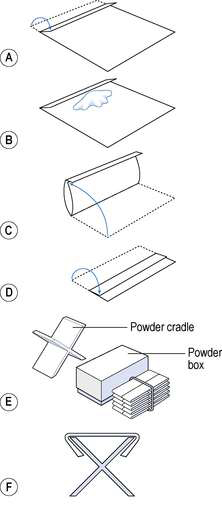

Folding papers

White glazed paper, called demy paper, is used for wrapping powders. A suitable size is 120 mm × 100 mm. The wrapping should be carried out on a clean tile or larger sheet of demy to protect the product. The papers should be folded with their long edges parallel to the front of the bench. Follow the steps illustrated in Figure 35.1 in order to fold the paper:

The creases can be sharpened with a spatula, taking care not to tear the paper or use excessive pressure which would compress the powder inside the pack.

The powders can be packed in pairs, back to back, or in one bundle, with the final powder placed back to back. They should be held together with an elastic band. In a well-wrapped product, there will be no powder in the fold or flaps, so that all the powder is available for easy administration when unwrapped.

Manufactured powders are subject to a uniformity of weight test, or uniformity of content test if each dose contains less than 2 mg of active ingredient or the content of active ingredient represents less than 2% of the total weight.

Shelf life and storage of internal powders

Extemporaneously prepared powders should have an expiry of between 2 and 4 weeks. Proprietary powders often have a longer shelf life because of the protective packaging. Some powders may be hygroscopic, deliquescent or volatile and will need to be protected from decomposition. Storage for these powders should be moisture proof and airtight.

Containers for internal powders

Extemporaneously prepared individually wrapped powders are often dispensed in a paperboard box. However, it is preferable to use a screw-top glass or plastic container which provides an airtight seal and protection against moisture. Proprietary powders in individual sachets which are moisture proof may be dispensed in a paperboard box. Bulk powders are packed in an airtight glass or plastic jar. A 5 mL spoon should also be supplied with bulk powders.

Special labels and advice for internal powders

Powders are usually mixed with water or another suitable liquid before taking, depending on their solubility. Powders for babies or young children can be placed directly into the mouth on the back of the tongue, followed by a drink to wash down the powder. Bulk powders should be shaken and measured carefully before dissolving or dispersing in a little water and taking.

Powders for external use

Powders, with or without medicament, are frequently applied to the skin. Dusting powders contain one or more substances in fine powder and may be dispensed as single-dose or multidose preparations (see Example 35.3). They are used to treat a variety of skin conditions or to soothe skin. Examples are antifungal powders for athlete’s foot or talc dusting powder for the prevention of chafing and skin irritation. Zinc oxide and starch are added to formulations to absorb moisture and talc is used for lubricant properties. Talc, kaolin and other natural mineral materials are liable to contamination with bacteria such as Clostridium tetani, C. perfringens and Bacillus anthracis. These ingredients should be sterilized by dry heat or the final product should be sterilized. Dusting powders should be sterile if they may be applied to large areas of open skin or wounds. They should not be used where there is a likelihood of large volumes of exudate, as hard crusts will form.

Example 35.3

Zinc, Starch and Talc Dusting Powder BPC. Mitte 100 g.

Zinc, Starch and Talc Dusting Powder BPC. Mitte 100 g.

| Master formula | For 100 g | |

| Zinc oxide | 25% | 25 g |

| Starch | 25% | 25 g |

| Sterilized purified talc 50% | 50 g |

Preparing powders for external use

A sieve size of 180 μm should be used to obtain the finely divided powder. The constituents should be mixed using the doubling-up method, as described previously.

Shelf life and storage for powders for external use

Dry powders should remain stable over a long period of time if packaged and protected from the atmosphere. For extemporaneously prepared products, an expiry of 4 weeks is appropriate.

Containers for powders for external use

Powders for external use may be packed in glass, metal or plastic containers with a sifter-type cap. Some are also available commercially in pressurized containers, containing other excipients such as a propellant and lubricants.

Special labels and advice for powders for external use

‘For external use only’ and ‘Store in a cool, dry place’.

Examples of official powders for external use include Zinc Oxide Dusting Powder Compound BPC, Chlorhexidine Dusting Powder BP and Talc Dusting Powder BP. Proprietary examples of powders for external use include Daktarin (miconazole), Cicatrin (neomycin sulphate, bacitracin zinc, cysteine, glycine and threonine) and Canesten powder (clotrimazole).

Action and uses. Non-steroidal anti-inflammatory drug, used to treat fever, pain and juvenile arthritis at a dose of up to 40 mg/kg daily.

Formulation notes. A diluent is not required, since the weight of each powder will be above the minimum 120 mg required. Pure ibuprofen powder can be used. However, if it is not available, manufactured 200 mg ibuprofen tablets (not modified release) can be used to prepare these powders.

Method of preparation. Take 14 × 200 mg ibuprofen tablets (contain 2.8 g ibuprofen) and weigh them. This is necessary to allow for the weight of the tablet excipients. Grind to a fine powder in a mortar and pestle. Pass the resulting powder through a 250 μm sieve and lightly remix. Divide the original weight of tablets by 20, and weigh aliquots of the resulting amount of powder. Pack into individual powder papers. Fasten the 18 powders together with an elastic band and pack in an amber glass jar or plastic container with a screw cap.

Shelf life and storage. Store in a cool, dry place. A shelf life of 2–3 weeks is appropriate.

Advice and special labels. The powders should be given after food, in water (or directly into the child’s mouth, followed by a drink of water).

Action and uses. A soothing preparation to absorb moisture and act as a lubricant, preventing friction in skin folds.

Method of preparation. Sieve the powders, using a 180 μm sieve, weigh and mix them by doubling-up in a mortar and pestle. Pack in an amber glass jar or plastic container with a screw cap (with a perforated, reclosable lid if possible).

Shelf life and storage. Store in a dry place. An expiry date of 4 weeks is advisable.

Advice and special labels. ‘For external use only’. Lightly dust the powder onto the affected area. The area should not be too wet as the powder will cake and abrade the skin. It should not be applied to broken skin or large raw areas.

Action and uses. Antacid preparation for dyspepsia.

Method of preparation. Sieve the powders, using a 250 μm sieve, weigh and mix them by doubling-up, using a mortar and pestle. Pack in an amber glass jar or plastic container with a screw cap.

Shelf life and storage. Store in a dry place. A 4-week expiry date is reasonable if kept dry.

Advice and special labels. ‘Dissolve or mix with water before taking’ (British National Formulary Label 13). A normal dose is 1–5 g of the powder taken in liquid, when required. Antacids are usually taken between meals and at bedtime.