Orthotics

Section 1: Hand Splinting: Principles, Practice, and Decision Making

Role of the occupational therapist

Anatomic structures of the hand

Mechanics of the hand and principles of splinting

When to splint and when not to splint

Step two: choosing appropriate material

Step three: choosing the type of traction

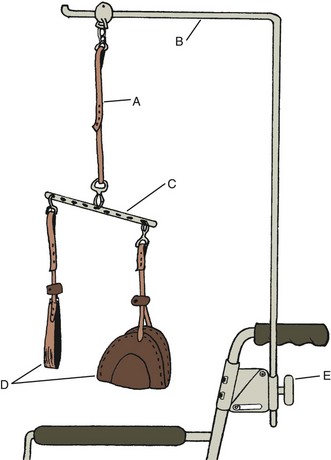

Section 2: Suspension Arm Devices and Mobile Arm Supports

After studying this chapter, the student or practitioner will be able to do the following:

1 Identify basic hand anatomy.

2 Describe the difference between single-axis and multiaxis joints and explain how they relate to splinting.

3 Define torque and describe how a splint produces torque.

4 Discuss the relationship of angle of approach to dynamic splinting.

5 Describe the three major purposes and goals of splints and when they should be employed.

6 Demonstrate an understanding of the principles of making a splint pattern.

7 Identify three characteristics of low-temperature thermoplastic material.

8 Discuss two ways in which splints may apply force.

9 Demonstrate how to determine the proper length of a forearm-based splint.

10 List the purposes of suspension arm devices.

11 Describe the limitations of the suspension arm support.

12 List the elements of adjustment for suspension arm devices.

13 Briefly describe the evolution of the traditional mobile arm support (MAS) and name its parts.

14 List the benefits of the MAS for persons with severe upper extremity weakness.

15 List the criteria for use of the MAS and describe how it works.

16 List two special parts of the MAS.

17 Describe the advantages of the JAECO-Rancho Multilink Mobile Arm Support.

According to Mosby’s Medical, Nursing, & Allied Health Dictionary, orthotics is “the design and use of external appliances to support a paralyzed muscle, promote a specific motion, or correct musculoskeletal deformities”; an orthosis is “a force system designed to control, correct, or compensate for a bone deformity, deforming forces, or forces absent from the body … [and] often involves the use of special braces”; and a splint is “an orthopedic device for immobilization, restraint, or support of any part of the body.”2 Splints and suspension arm devices can be considered orthoses. Occupational therapists (OTs) often design and construct splints. An orthotist usually designs and constructs suspension arm devices, and OTs adjust them and train clients to use them. In practice, the term orthosis is used more frequently to refer to suspension arm devices than splints. Hand splinting is the topic of Section 1 of this chapter, and suspension arm devices are described in Section 2.

Section 1 Hand Splinting: Principles, Practice, and Decision Making

The human hand is the brain’s most important instrument for exploring and mastering the world. We read with our hands if we suffer loss of vision; we communicate with our hands in the absence of speech or hearing. Our hands give us expression and console us. We first explore our hands and explore with our hands as infants. The wonder of the human hand is the precision with which it functions and the extremes of abuse it tolerates. We can and do take our hands for granted as they complete a multitude of functional tasks such as dressing, cooking, or typing, because they seem to function effortlessly—that is, until we experience some level of impairment or dysfunction.

The hand does not function independently of the whole human organism. It is connected to the brain via a complex tangle of nerves and is dependent on precise synaptic connections. The hand does not function independently of the upper extremity (UE); stability and control of the shoulder, elbow, and wrist are needed to position the hand in space. Dysfunction anywhere from the brain to the fingertips may cause impaired function of the hand.

Humans achieve mastery and independence over their environment because of the superiority of the human brain and the dexterity of the hand. Tying a knot, opening a necklace clasp, wielding a hammer, and throwing a ball are abilities unique to the human hand. That we can close a necklace with our vision occluded is testament to the sensibility of the hand. That we can wield a hammer to drive a nail is testament to the integrity of the skin and the strength of the muscles that power the hand. That we can speak volumes with a sweep of our hands or a caressing touch is testament to the aesthetics of the hand. It is a remarkable instrument indeed. As Mary Reilly, one of the profession’s most recognized leaders, stated in her 1961 Slagle lecture, “Man through the use of his hands as they are energized by mind and will, can influence the state of his own health.”

OTs deal with the human being as a whole, not just as a hand, a toe, or a shoulder. With the human hand, even the smallest impairment may affect function. Loss of placement of the hand may mean an inability to achieve a hand-to-mouth pattern, which makes independent feeding impossible. Pain and fear can and do accompany injury, and when independence or livelihood is threatened by hand dysfunction, the outcomes are often dramatic, affecting that person and the family members who rely on him or her. The hand is perhaps most valued only when it ceases to function and we must give it attention.

A splint is one of the most important tools therapists use to minimize or correct impairment and to restore or augment function. Little else so readily calls attention to the hand as a splint. An individual may not receive comments on a new ring or a recent manicure, but put a splint on the hand and all will take notice. The decision to provide or fabricate a splint requires an in-depth understanding of the pathologic condition to be affected and of the many splinting choices available.

Section 1 of this chapter serves as an introduction to the anatomic and biomechanical principles necessary for an understanding of the basic concepts and models of splinting. This section briefly reviews the anatomy of the hand and its relationship to principles of splinting, introduces the biomechanical principles involved in splint design and fabrication, and introduces a splint fabrication process involving pattern making, material choices, types of traction, and techniques of fabrication.

Role of the Occupational Therapist

The education an OT receives in analysis of activity and assessment of human occupation and function leads naturally to the use of splinting as one therapeutic tool in the intervention regimen. OTs most commonly fabricate splints for the hand and UE, but they may be called upon to design and fabricate splints for the lower extremity (LE) and even for the back or spine. The basic principles of splinting apply, regardless of which body part is being splinted.

Involvement of the OT in all phases of splint fabrication is recommended from the initial assessment of need, through the design phase, the fabrication, and the training and follow-up necessary to ensure proper use and fit of the splint. This involvement requires an understanding of the anatomy and biomechanics of the normal, unimpaired hand and of the pathology of the impaired hand. Many excellent texts describe both hand anatomy and biomechanics in extensive detail and should be included in the library of any OT treating the hand. This chapter briefly reviews the anatomy and biomechanics of the hand most pertinent to splinting. The lists of references and suggested readings at the end of this chapter provide several excellent selections for further study.

One reference of note that should be included in every therapist’s library is Clinical Mechanics of the Hand,8 3rd edition, by Paul W. Brand and Anne Hollister. This text is an excellent source for a straightforward explanation of the mechanics of muscles, joints, and skeletal structures and how they contribute to the remarkable dexterity and strength of the hand. Brand and Hollister discuss clinical approaches and how they affect the natural biomechanics of the hand.

Anatomic Structures of the Hand

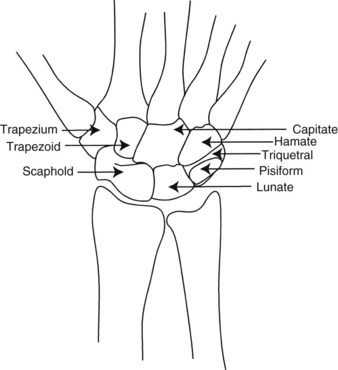

The hand and wrist are a complex of 27 bones that contribute to the mobility and adaptability of the upper extremity; the 54 bones that make up both hands and wrists account for approximately one fourth of the total bones of the human body. The wrist is a complex that consists of the distal ulna and radius and the eight carpal bones arranged in two rows. The carpal bones form the concave transverse arch and, with the configuration of the distal radius, contribute substantially to the conformability of the hand.28 The distal ulna does not articulate with any carpal bone, and its contribution to wrist stability is made through the attachments of the ulnar collateral ligament, which places a check on radial deviation (Figure 30-1).

The wrist complex allows a greater arc of motion than any other joint complex except the ankle. This mobility is the result of a unique skeletal configuration and an involved ligamentous system. All motion at the wrist is component motion that occurs in more than one anatomic plane; no pure or isolated motions occur. This concept is key in any treatment directed at the wrist. Extension occurs with a degree of radial deviation and supination. Wrist flexion includes ulnar deviation and pronation. The wrist is contiguous and continuous with the hand. The distal carpal row (the trapezium, trapezoid, capitate, and hamate) articulates firmly with the metacarpals. Motion is produced across these articulations by muscles that cross the carpals and attach to the metacarpals. The proximal carpal row (the scaphoid, lunate, and triquetrum) articulates distally with the distal carpal row, and proximally with the radius and the triangular cartilage. Gliding motions occur between the carpal rows during flexion, extension, and deviation, and excessive motion is checked by the carpal ligaments.

Placement of the hand for functional tasks is reliant on the stability, mobility, and precision of placement permitted by the wrist complex. Any mechanism of injury or disease that alters this complex system, such as rheumatoid arthritis, translates into some level of dysfunction. Even the simplest splint that crosses the wrist will alter in some way the functional abilities of the hand.

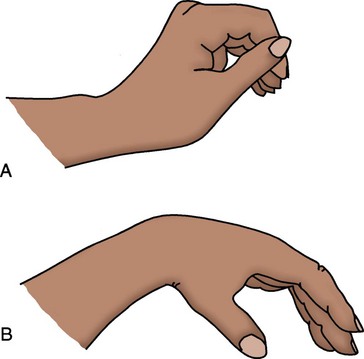

Wrist Tenodesis: Tenodesis is the reciprocal motion of the wrist and fingers that occurs during active or passive wrist flexion and extension. Tenodesis is the action of wrist extension producing finger flexion, and wrist flexion producing finger extension. It is caused by lack of change in length of the long finger muscles during wrist flexion or extension (Figure 30-2). The extrinsic finger muscle tendon units have a fixed resting length; because they cross multiple joints before inserting onto the phalanges, they can affect the position of several joints with no contraction or length change required of the muscles. This concept is crucial for understanding how passive positioning of the wrist affects the resting position of the digits. In the nerve-injured hand, tenodesis is often harnessed by splints to provide function. The client with spinal cord injury with sparing of a wrist extensor (C6 or C7 functional level) gains considerable function from a tenodesis, or wrist-driven flexor hinge hand splint. In a dynamic splint, such as a tenodesis splint, the effect that tenodesis has on tendon length will dictate in part the wrist position that will optimize forces directed at the digits.

Metacarpal Joints

The metacarpals articulate with the carpal bones proximally and with the phalanges distally. The first metacarpal, the thumb, articulates with the saddle-shaped trapezium and is considered separately. The second metacarpal fits into the central ridge of the trapezoid, and the third articulates firmly with the facets of the capitate. These articulations form the immobile central segment of the hand around which the other metacarpals rotate. The fourth and fifth metacarpals articulate with the concave distal surface of the hamate. The shorter length of the ulnar two metacarpals and their greater mobility form the flexible arches of the hand; this allows it to conform and fold around objects of various shapes.

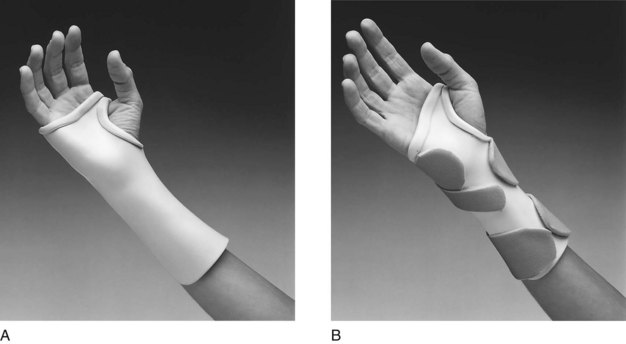

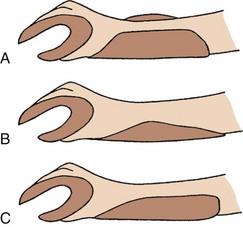

The distal transverse arch of the hand lies obliquely across the metacarpal heads. This obliquity is critical to the ability of the hand to adapt its shape to objects. The hand does not form a cylinder as it closes but instead assumes the position of a cone. In making a fist, the ulnar two digits of the hand contact the palm first, and the radial two digits follow. This cascade of the fingers is a direct result of the oblique angle formed at the metacarpal heads (sloping angle, not parallel to the wrist). This concept is most important in splinting in determining the distal trim lines for a wrist support when full metacarpophalangeal (MP) flexion is desired. The splint in Figure 30-3, A, is improperly trimmed distal to the MP creases. Distal trim lines should be established proximal to the MP creases, as in Figure 30-3, B.

Metacarpophalangeal Joints

The distal heads of the metacarpals articulate with the proximal phalanges to form the MP joints. Active motion is possible along an axis of flexion and extension, and along an axis of abduction and adduction. In addition, a small degree of rotation is present at the MP joints. These axes of motion allow for expansion or spreading of the hand and contribute to the ability of the hand to conform to different shapes and sizes of objects. An attempt to hold a softball without abduction of the fingers shows the importance of this motion. A splint with trim lines along the ulnar border of the hand that extend too far distally limits flexion and abduction of the fourth and fifth digits. As a result, the hand will have a limited ability to grasp large objects, and function will be restricted (Figure 30-4, A). Distal trim lines that fall proximal to the MP creases will allow for full MP flexion (Figure 30-4, B).

Thumb

The base of the first metacarpal articulates with the trapezium to form a highly mobile joint that often is compared with the shape of a saddle. The base of the first metacarpal is concave in the anteroposterior plane and convex in the lateral plane. This surface is met by reciprocal surfaces on the trapezium. This configuration allows for a wide arc of motion, with the thumb able to rotate not only for pad-to-pad opposition, but also for full extension and abduction to move away from the palm.28 Both motions are important to function, that is, a thumb posted in permanent opposition may make grasp possible but release of objects impossible. This concept is crucial to an understanding of splints that augment the tenodesis action of the hand by posting the thumb in opposition to the index and long fingers. With such splints, the therapist must carefully consider the degree of abduction and opposition in which the thumb is posted, to maximize both grasp and release.

Interphalangeal Joints

The proximal interphalangeal (PIP) and distal interphalangeal (DIP) joints are true hinge joints, with motion in only one plane. This limitation of motion ensures greater stability in these joints, which contributes to their ability to resist palmar and lateral stresses, and so imparts strength and precision to functional tasks.

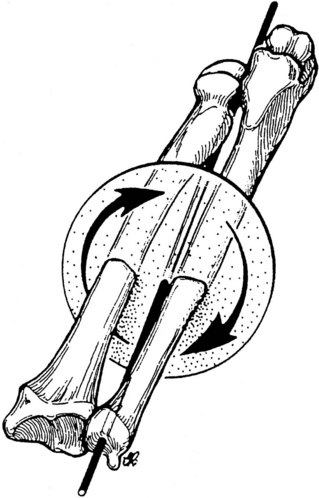

Forearm Rotation

Close consideration of forearm rotation (i.e., supination and pronation) is necessary because of the importance of these motions to function and to the fitting of splints. Forearm rotation occurs at the elbow and at the distal forearm, with axes of rotation through the center of the radial head and capitulum and along a line extending through the base of the ulnar styloid (Figure 30-5). During pronation, the ulnar styloid moves laterally, as the radial styloid travels medially. During supination, the opposite occurs, with the ulnar styloid moving medially. This movement results in displacement of the styloids, which in turn alters the architecture of the forearm in supination as compared with pronation.

FIGURE 30-5 The axis of motion for supination and pronation extends the length of the forearm and is centered through the radial head and capitulum and the distal ulnar styloid. (From Colello-Abraham K: Rehabilitation of the hand, ed 3, St Louis, 1990, Mosby.)

The way in which this change in dimensions affects splint trim lines is shown in Figure 30-6. Lines drawn at midline along the supinated forearm shift dramatically upon pronation. Splints are generally used for function with the forearm in pronation, but they are easier to fabricate with the forearm in supination. Important to note is that if the forearm is not pronated before the splint material is set, the trim lines will be high on the radial border and low on the ulnar border.

FIGURE 30-6 The shape of the forearm is altered as it moves from supination to pronation. Forearm-based splints must be repositioned to accommodate this if the forearm is rotated during the fabrication process. (From Wilton JC: Hand splinting, principles of design and fabrication, Philadelphia, Pa, 1997, WB Saunders.)

One final active demonstration highlights the importance of forearm position for hand function. Place a coin of any size on a tabletop, and while holding the forearm in neutral (thumb straight up), attempt to pick up the coin. It becomes rapidly apparent that the ability to position the hand for function relies in great part on the more proximal joints of the forearm.

Ligaments of Wrist and Hand

The ligamentous structures of the hand act as checkreins for the hand and wrist; this limits extremes of motion and provides stability. The complex motions of the wrist depend in large part on the ligaments that restrain them, rather than on the contact surfaces between the carpals and metacarpals. Three groups of ligaments are discussed briefly to highlight their contribution to wrist stability and mobility.

The palmar ligaments include the radioscaphocapitate ligament, which contributes support to the scaphoid; the radiolunate ligament, which supports the lunate; and the radioscapholunate ligament, which connects the scapholunate articulation with the palmar surface of the distal radius. The stability and mobility of the thumb and radial carpus depend on the integrity of these ligaments. Disruption of the ligaments results in instability and pain at the wrist and in significant dysfunction of the thumb. Splinting is frequently the treatment of choice to supply stability for pain reduction.

The radial and ulnar collateral ligaments provide dorsal stability. These capsular ligaments, along with the radiocarpal and dorsal carpal ligaments, provide carpal stability and permit ROM. Disruption of any of these ligaments may result in pain, loss of strength, and functional impairment.

The triangular fibrocartilage complex (TFCC) includes the ligaments and the cartilaginous structures that suspend the distal radius from the distal ulna and the proximal carpus. Tears or strains in this complex are evidenced by pain and weakness with resultant loss of function in resistive tasks. The advent of new imaging techniques has made the diagnosis of TFCC tears more common; splinting is often ordered for support and pain relief.

Metacarpophalangeal Joints: Soft tissue structures that surround the MP joints include the joint capsule, the collateral ligaments, and an anterior fibrocartilage or volar plate. The capsule covers the head of the metacarpal and is reinforced by the collateral ligaments. The collateral ligaments are configured to allow side-to-side motion when the MP is in extension, and to tighten as the MP is flexed. The volar plate is attached to the base of the proximal phalanx and is loosely attached to the base of the neck of the metacarpal through the joint capsule. This configuration allows for sliding of the plate proximally during MP flexion. The plate returns to its lengthened state with the MP in extension and acts as a checkrein for volar displacement of the MP joint when it is extended.

When MPs are immobilized in extension, a strong tendency exists for secondary shortening of the lax collateral ligaments, in addition to contraction and adherence of the volar plate, which results in limited MP flexion and loss of functional grasp patterns. The commonly accepted resting position splint, which places the wrist in 25 degrees to 35 degrees of extension, the MP joints at 60 degrees to 70 degrees of flexion, and the PIP and DIP at 10 degrees to 35 degrees of flexion, is designed to prevent shortening and to maintain the joints in midrange for optimal function. An important consideration is to ensure that the mobile fourth and fifth digits are positioned in the splint to accommodate their additional degree of mobility by allowing somewhat greater flexion at their MP joints (Figure 30-7).

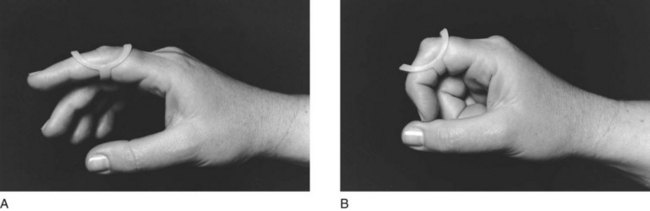

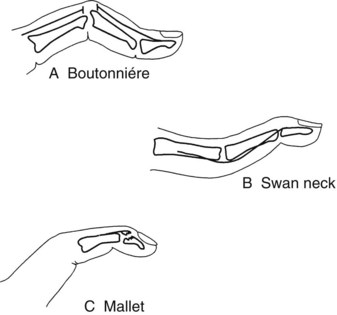

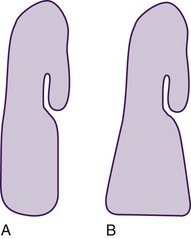

Proximal Interphalangeal Joints: The PIP joint capsule and ligaments provide stability and allow mobility in one plane only. Collateral ligaments on each side of the joint run in a dorsal-to-palmar direction, inserting into the fibrocartilage plate of the PIP. These ligaments and the plate are lax with the PIP joint in flexion and taut with it in extension. The seemingly simple joint is made more complex by inclusion of the extensor mechanism passing through the capsule dorsally and contributing slips to the system of ligaments affecting this joint. The potential for disruption of the extensor mechanism is high. Many of the most commonly fabricated finger splints are used to correct PIP boutonniere (Figure 30-8, A) and swan-neck (Figure 30-8, B) deformities.

FIGURE 30-8 A, Boutonniere deformity, or joint change, characterized by proximal interphalangeal joint flexion and distal interphalangeal joint hyperextension. B, Swan-neck deformity, or joint change, with proximal interphalangeal joint hyperextension and distal interphalangeal joint flexion. C, Mallet finger with distal interphalangeal joint flexion and loss of active extension.

Distal Interphalangeal Joints: The DIP joint capsule and ligaments are similar to the PIP joint but have less structural strength to the terminal insertions of the palmar plate and collateral ligaments. As the structures become smaller, they lose integrity and strength. One of the most frequent injuries to the digits is disruption of the terminal end of the extensor tendon, which results in a mallet or “baseball” finger (Figure 30-8, C).

Muscles and Tendons of Forearm, Wrist, and Hand

Balance in the hand must be considered when the hand is assessed for a splint. Two groups of muscles act on the wrist and hand: (1) the extrinsic muscles that arise from the elbow and the proximal half of the midforearm, and (2) the intrinsic muscles with origins and insertions entirely in the hand. The extrinsic muscles include both a flexor and an extensor group acting on the wrist and on the digits. The intrinsics include the lumbricals, the dorsal and palmar interossei, and the thenar and hypothenar groups. Smooth, coordinated motions of the hand in functional activities depend on a well-integrated balance between and within these two muscle groups. Many of the contractures that OTs attempt to correct with splinting are caused by neurologic dysfunction (central or peripheral), which results in imbalance of muscle tone or innervation.

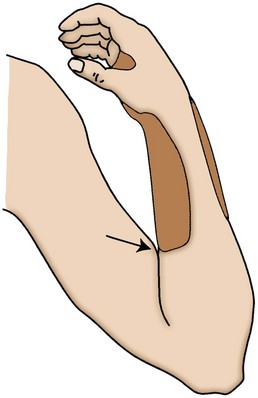

Nerve Supply

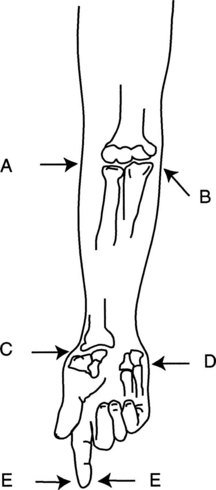

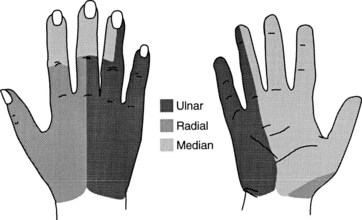

A discussion of the nerve supply to the hand should include mention of the continuity of the brachial plexus from its origins in the spinal cord to its terminal innervations in the hand. Injuries or compressions that occur anywhere along this continuum may result in motor or sensory dysfunction. When splinting the UE, the therapist must give attention to the pathways of the nerves that supply the UE and to potential sites for nerve entrapment. In the fabrication of splints, care must be taken to avoid applying pressure over sites where the nerves are superficial and prone to compression. These sites include the ulnar nerve at the elbow in the cubital tunnel and in Guyon’s canal at the ulnar border of the wrist, the radial nerve at the elbow and in the thenar snuffbox, and the digital nerves along the medial and lateral borders of the digits (Figure 30-9).

FIGURE 30-9 Potential sites for nerve compression from improperly fitted splints. A, Radial nerve. B, Ulnar nerve. C, Radial digital nerve in anatomic snuffbox. D, Ulnar nerve in Guyon’s canal. E, Digital nerves.

Three peripheral nerves supply motor and sensory function to the hand (Figure 30-10). The radial nerve is the primary motor supplier to the extensor and supinator muscles. The sensory fibers of the radial nerve supply the dorsum and the radial border of the hand. The median nerve provides motor supply to the flexor-pronator group, which includes most of the long flexors and the muscles of the thenar eminence. The sensory distribution of the median nerve is functionally the most important because it includes the palmar surface of the thumb, index, and long fingers and the radial half of the ring finger. The ulnar nerve supplies most of the intrinsic muscles, the hypothenar muscles, the ulnarmost profundi, and the adductor pollicis brevis. The sensory supply of the ulnar nerve includes the palmar surface of the ulnar half of the ring finger, the little finger, and the ulnar half of the palm.

FIGURE 30-10 Sensory distribution in hand. Median nerve distribution includes most of the prehensile surface of the palm.

Nerve dysfunction presents a challenge to the splint maker. Muscle imbalance leads to dysfunctional posturing of the hand and muscle atrophy that reduces the natural padding of the hand. Abrasions or ulcerations may occur in persons who do not remove their splints, because they do not feel pain caused by shearing forces or pressure areas inside the splint. Finally, skin with marked sensory impairment lacks natural oils and perspiration; this leads to dry skin that abrades easily. These factors must be assessed and considered carefully when splints are being fitted on persons with sensory impairment.

Splinting the neurologically impaired hand is directed at preventing joint and soft tissue contractures and restoring functional positioning. Splinting cannot restore sensibility, and care must be taken to prevent damage to sensory-impaired skin and to limit further reduction of sensory feedback by covering sensate surfaces (those surfaces that have sensation) and consequently reducing functional use of the hand in ADLs.

Little consensus has been reached on whether or not splinting the neurologically impaired hand is best practice and should or should not be done, and for what long-term goals. An excellent summary of this debate is provided by Lohman and Aragon in “Introduction to Splinting: A Clinical Reasoning and Problem-Solving Approach” (Chapter 14).10

Blood Supply

Blood supply to the hand is contributed by the radial and ulnar arteries. The ulnar artery lies just lateral to the flexor carpi ulnaris tendon, where it divides into a large branch that forms the superficial arterial arch and a small branch that forms the lesser part of the deep palmar arch. The ulnar artery is vulnerable to trauma where it passes between the pisiform and the hamate (Guyon’s canal). The radial artery divides at the proximal wrist crease into a small, superficial branch and a larger, deep radial branch. The superficial arterial arch further divides into common digital branches and then into proper digital branches.

Venous drainage of the hand is accomplished by two sets of veins: a superficial and a deep group. Therapists are more likely to be concerned with the superficial venous system because it lies superficially in the dorsum of the hand. Disruption of this superficial system may result in extensive fluid edema in the dorsum of the hand, which requires the therapist’s intervention. Care must be taken not to strap splints too tightly over the dorsum of the hand; this traps fluids from draining.

Skin

The mobility of the hand is directly related to the type and condition of the skin. Anyone who has put on a ring that is slightly too small, only to be unable to remove it, has experienced the redundancy of the skin on the dorsum of the hand. The skin on the dorsum of the hand is loosely anchored to underlying structures and moves easily to allow flexion and extension of the digits. The ring “problem” occurs because of a greater degree of elasticity in the dorsal skin when it is pulled distally, as opposed to when it is pulled proximally. This fact should be considered when the use of finger splints is contemplated.

The palmar skin, by contrast, is thicker and relatively inelastic. It is firmly connected to the underlying palmar aponeurosis for stability and protection during prehension activities. Furthermore, the underlying fascia of the palmar skin is thicker and protects the nerve endings, while it acts to supply adequate moisture and oils to the skin surface.

Superficial Anatomy and Landmarks

When fabricating a splint, therapists must consider where to apply force without causing further trauma. Despite its deftness and power, the hand’s lack of protective fascia means that it tolerates external pressures poorly and shearing stresses not at all. The prominent ulnar styloid, the distal radial styloid, and the thumb carpometacarpal joint are common sites for pressure. A truism that will always hold in splinting is that padding adds pressure. The softest padding added to a too-tight splint will only add more pressure. Pressure is relieved by the creation of a relief in the splint or by application of padding and material molded over the pad to make it an integral part of the splint (Figure 30-11). Added padding to relieve pressure after the splint is formed should be avoided.

Prehension and Grasp Patterns

The ability of the human hand to assume myriad functional positions and to apply only the precise amount of pressure necessary to hold an object is a result of the mobility and stability supplied by the skeleton, the power of the muscles, and the remarkable degree of sensory feedback received from the nerves. This sensory feedback is used to assess the size, shape, texture, and weight of an object. The brain then determines which type of prehension to use to complete a functional task while using this object. The feedback used in grasping and lifting an object is dependent both on the brain’s interpreting correctly what is seen and on the hand’s responding appropriately. Once an object is in the hand, further adaptation in prehension will occur if the initial visual assessment was faulty.

Splints can maximize functional prehension. In achieving this goal, the therapist must be aware of what a splint can and cannot do: a splint can stabilize an unstable part, position a thumb in opposition, and even assist or substitute for lost motion. A splint with added dynamic components can even gradually revise tissue along its lines of pull by applying slow gentle stretch to gain increased functional range of motion. However, the splint maker must be aware that a splint may negatively limit mobility at uninvolved joints, reduce sensory feedback, add bulk to the hand, and transfer stresses to unsplinted joints proximal or distal to the part being splinted.

The prehension patterns the hand is able to achieve are as exhaustive as the objects that are available to grasp or pinch. Several authors have contributed to classifications of normal prehension, and the presentation by Flatt12 is recommended for further study of the subject. It is possible to reduce the many patterns to two basic classifications—prehension and grasp—from which other patterns may be derived. Prehension is defined as “a position of the hand that allows finger and thumb contact and facilitates manipulation of objects.” Grasp is defined as “a position of the hand that facilitates contact of an object against the palm and the palmar surface of partially flexed digits.”

The thumb is involved in all but one type of grip, that of hook grasp. Carpometacarpal and MP rotation is crucial to prehension and cannot be overstressed in terms of its importance in splinting to achieve function. This rotation allows for full contact of the thumb in pad-to-pad prehension; this motion is used in a normally active person hundreds of times daily in performance of all areas of occupation, including ADLs, instrumental activities of daily living (IADLs), work, leisure, and social participation.

Lateral Prehension

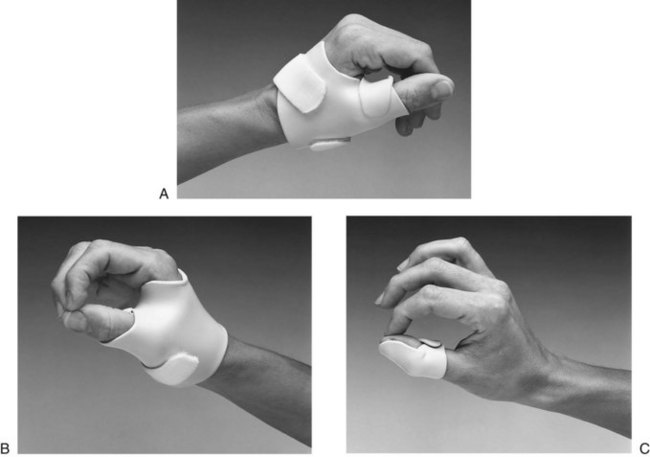

In lateral prehension, the pad of the thumb is positioned to contact the radial side of the middle or distal phalanx of the index finger (Figure 30-12, A). Most commonly, this pattern of prehension is used in holding a pen or eating utensil, and in holding and turning a key. The short or long opponens splint is used to stabilize the thumb to achieve this prehension pattern.

FIGURE 30-12 A, Lateral prehension or key pinch in short opponens splint that positions thumb in lateral opposition to index finger. B, Palmar prehension or three-jaw chuck pinch in short opponens that positions thumb in opposition to index and long fingers. C, Tip prehension with thumb and index finger in interphalangeal blocker that secures interphalangeal joint in slight flexion to assist tip prehension.

Palmar Prehension

Palmar prehension is also called “three-jaw chuck pinch.” The thumb is positioned in opposition to the index and long fingers (Figure 30-12, B). The important component of motion in this pattern is thumb rotation, which allows for pad-to-pad opposition. This prehension pattern is used in lifting objects from a flat surface, in holding small objects, and in tying a shoe or bow. The short and long opponens splints may be fabricated to position the thumb in palmar prehension.

Tip Prehension

In tip prehension, the IP joint of the thumb and the DIP and PIP joints of the finger are flexed to facilitate tip-to-tip prehension (Figure 30-12, C). These motions are necessary for picking up a pin or a coin. It is difficult to substitute for tip prehension because it is rarely a static holding posture. Once a pin is in the hand, tip prehension will convert to palmar prehension to provide more skin surface area to retain a small object. A thumb IP hyperextension block is useful in limiting IP hyperextension and in facilitating the IP flexion required for tip prehension. In the case of Alexei, maximal edema and stiffness prevented him from achieving the tip or palmar prehension needed for his diabetes management, which included manipulation of small objects.

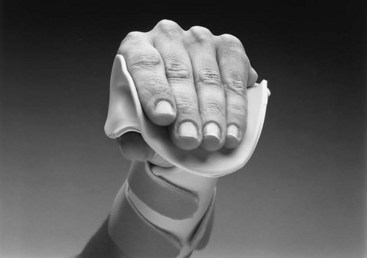

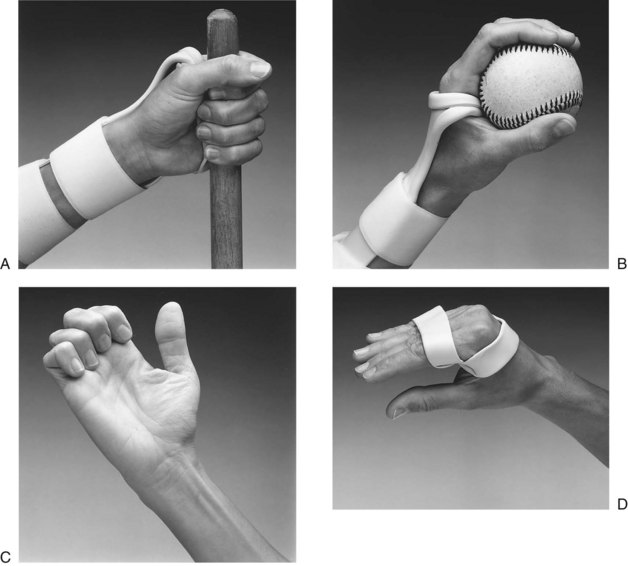

Cylindrical Grasp

Cylindrical grasp, the most common static grasp pattern, is used to stabilize objects against the palm and the fingers, with the thumb acting as an opposing force (Figure 30-13, A). This pattern is assumed for grasping a hammer, a pot handle, a drinking glass, or the handhold on a walker or crutch. Static splinting offers little to restore this grasp directly, although positioning the wrist in extension offers greater stability to the hand as it assumes this grasp pattern. However, a dynamic outrigger component can be added to a volar splint to gently gain increased MP and PIP flexion to enhance cylindrical grasping ability, as was found to be successful for Alexei. A dorsal wrist stabilizer alone offers stability while minimizing palm coverage.

FIGURE 30-13 A, Cylindrical grasp in dorsal splint that stabilizes wrist to increase grip force and minimizes palm covering. B, Spherical grasp in dorsal splint. Splint stabilizes wrist to increase grip force and permits metacarpal mobility required for spherical grasp. C, Hook grasp does not involve thumb. Grasp pattern is seen in median and ulnar neuropathy; splinting is aimed at correcting rather than augmenting grasp. D, Figure-eight splint substitutes for loss of intrinsic function with median and ulnar neuropathy.

Spherical Grasp

Also called ball grasp, this pattern is assumed for holding a round object, such as a ball or an apple. It differs from cylindrical grasp primarily in positioning of the fourth and fifth digits. In cylindrical grasp, the two ulnar metacarpals are held in greater flexion. In spherical grasp, the two ulnar digits are supported in greater extension to allow a more open hand posture (Figure 30-13, B). In splinting, to facilitate or support this pattern of grasp, the wrist-stabilizing splint must be trimmed proximal to the distal palmar crease and contoured to allow for obliquity at the fourth and fifth metacarpal heads.

Hook Grasp

Hook grasp is the only prehension pattern that does not include the thumb to supply opposition. The MPs are held in extension, and the DIP and PIP joints are held in flexion (Figure 30-13, C). This is the attitude the hand assumes when holding the handle of a shopping bag, a pail, or a briefcase. In the nerve-injured hand, splinting is directed more commonly at correcting this posture by flexing the MPs than at facilitating it.

Intrinsic Plus Grasp

Intrinsic plus grasp is characterized by positioning of all MPs of the fingers in flexion, the DIP and PIP joints in full extension, and the thumb in opposition to the third and fourth fingers (Figure 30-13, D). This pattern is used in grasping and holding large, flat objects such as books or plates. Intrinsic plus grasp is often lost in the presence of median or ulnar nerve dysfunction, and a figure-eight or dynamic MP flexion splint is used for substitution.

Mechanics of the Hand and Principles of Splinting

McCollough and Sarrafian stated that the three basic motor functions of the upper limb are “prehension and release, transfer of objects in space, and manipulation of objects within the grasp.”20 These functions depend on the structural integrity of the skeleton, the muscles that provide power, and the feedback to which the brain responds when enabling the limb to meet functional demands. The task of restoring any one of these basic functions through the application of a splint is complex and relies on an understanding of the biomechanics of the hand and the mechanics involved in splinting. It is beyond the scope of this chapter to present this topic in depth. Presented here is an introduction to those tenets of clinical mechanics deemed necessary for the beginning splint maker.

Mechanics deals with the application of force, and biomechanics may be viewed as the body’s response to those forces. In the hand, the force required to produce motion is supplied by muscles. The force then is transmitted by the tendons to the bones and joints, with control supplied by the skin and pulp of the fingers and palm.11 How the application of a splint affects the transmission of force to produce motion depends on the relationship between the axis of rotation of joints and anatomic planes and the forces imposed on the hand.

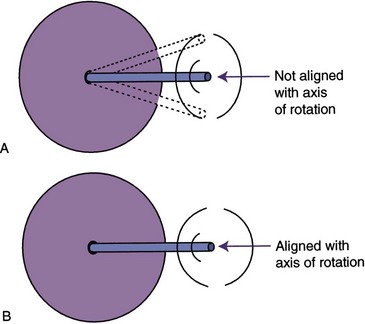

Axis of Motion

Hollister and Giurintano14 define axis of motion as “a stable line that does not move when the bones of a joint move in relation to each other” (Figure 30-14). This stable line is illustrated by Figure 30-14, B, which shows a tire perfectly balanced around its axis of motion. When a tire is perfectly balanced, it does not wobble; it has pure motion around a single point.

FIGURE 30-14 A, If a tire is not balanced around its axis, it wobbles. If a splint hinge is not aligned with the joint axis, wobble is seen as binding of the joint. B, Proper alignment of a tire or of a hinge with an anatomic joint results in smooth, unimpeded motion.

In a single-axis joint, motion occurs in only one plane. The PIP joint is an example of a single-axis joint in alignment with an anatomic plane. It moves only in the plane of flexion and extension.

Joints that have more than one axis of motion may move in more than one plane at a time. For example, the wrist complex has two axes of motion: flexion-extension and radial-ulnar deviation. A joint with multiple axes has conjoint motions that occur in addition to the primary motions described by the joint. Wrist flexion occurs with a moment of ulnar deviation and with a small degree of pronation. Wrist extension occurs with radial deviation and slight supination. These conjunct motions are what make circumduction of the wrist possible. They are also what make splinting the wrist with hinged joints a challenge.

A splint with a movable hinge or coil has a single axis. When used to splint a single-axis joint such as a PIP joint, a hinge can and should be properly aligned to avoid binding that will limit motion. If a single-axis hinge or coil is used to reproduce motion in a multiaxis joint, some binding or friction will always occur, no matter how well aligned, because the hinge or coil does not allow for, or reproduce, the conjunct motions available in the unsplinted joint.

Force

It is crucial to understand basic principles of force and apply them correctly in splinting. An understanding of the forces applied by levers and the stresses that occur between opposing surfaces can help to explain what happens as forces are applied within the body by muscles and externally by splints.

Definitions: Use of the term force, as it relates to splinting, describes the effects that materials and dynamic components have on bone and tissue. Force is a measure of stress, friction, or torque. Stress is resistance to any force that strains or deforms tissue. Shear stress occurs when force is applied to tissues at an angle or in opposing directions. Pinching skin between the surface of a splint and the underlying bony structures causes shear stress.

Friction occurs when one surface impedes or prevents gliding of a surface on another. Friction is produced in the stiff or contracted joint when soft tissue restriction prevents gliding of the bones. Splints may contribute to friction if they are misaligned in relation to a joint axis. For example, a hinged splint that is not properly aligned with the axis of rotation will limit motion by producing friction as the joint attempts to move.

Torque is a measure of the force that results in rotation of a lever around an axis. The torque created when a lever rotates depends on the force used and the length of the lever employed. In the body, muscles are the levers that create torque when they act to move a joint. Externally, splints may act as levers to apply the force necessary to move a bone around its axis. The measure of torque is given by the following formula:

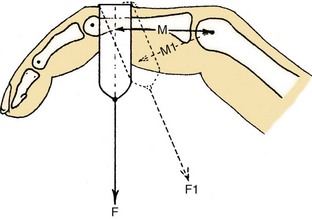

Internally, the length of the lever arm is measured as the perpendicular distance from the axis of the joint to the tendon. Externally, the length of the lever arm is measured as the estimated distance from the joint axis to the attachment of force. In splinting, the attachment point of the force is usually a soft or molded cuff. If the splint includes an outrigger with a finger cuff, as shown in Figure 30-15, the lever arm is the distance from the axis of the joint to the finger cuff, as indicated in line M.

FIGURE 30-15 Tension F on the phalanx has a moment arm of M acting on the joint. Tension F1 has a smaller moment arm, M1 (with less resulting torque), when the angle of approach is not 90 degrees. (From Brand PW, Hollister A: Clinical mechanics of the hand, ed 2, St Louis, 1993, Mosby.)

Figure 30-15 demonstrates that the angle of approach of the force to the finger also affects the length of the lever arm and ultimately the torque applied. The angle of approach is the angle that the line of traction makes as it meets the part being splinted. When the angle of approach is at a right angle (90 degrees) to the long axis of the phalanx, the lever arm is M. When the cuff is at less than 90 degrees to the long axis of the phalanx, the lever arm is shortened to M1. This shorter lever arm will produce less torque and therefore less rotation unless greater force is applied.

Given an equal amount of resistance or load, a 2-foot lever will require half as much force to create motion around an axis as will a 1-foot lever. The important principle for splint makers is that as the distance between the attachment of the cuff or strap and the joint axis increases, less force is required to achieve motion.

Translational Forces: In addition to the angle of approach affecting the length of the lever arm, an approach of less than or greater than 90 degrees results in translational forces. The outrigger splint in Figure 30-16, A, shows a 90-degree angle of approach between the nylon line and the phalanx, demonstrating the correct angle of pull.

FIGURE 30-16 A, Angle of approach is 90 degrees to middle phalanx, ensuring that force pulling the proximal interphalangeal joint into extension is not causing distraction or compression. B, Angle of approach less than 90 degrees to middle phalanx causes joint compression. C, Angle of approach greater than 90 degrees distracts joint.

When force is applied at any angle other than 90 degrees, translational forces are created. This alteration of the angle of approach translates some of the rotational force away from producing joint extension and directs the force into joint compression or joint distraction (Figure 30-16, B and C). The greater the deviation from 90 degrees, the greater is the translational force. Depending on the type of splint and the condition of the joint, joint compression or distraction may lead to mere discomfort or to actual joint damage. Translational force is also undesirable because it undermines the effectiveness of the splint by shortening the lever arm.8

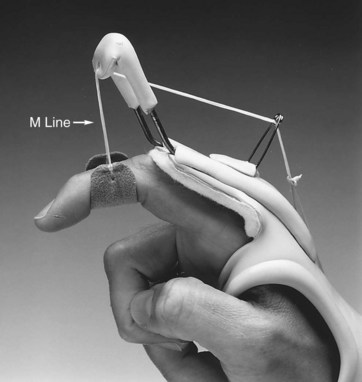

The challenge in splinting with an outrigger is to position the splint so that a 90-degree angle of approach exists. In the outrigger in Figure 30-17, as long as the finger does not move, the 90-degree angle will remain. As soon as the finger moves, however, the 90-degree angle changes. Because few outriggers allow for this automatic readjustment in position, the outrigger must be adjusted as the contracture lessens to maintain the 90-degree angle of approach.

FIGURE 30-17 As dynamic traction acts on range of motion at the proximal interphalangeal joint, splint must be adjusted to maintain 90-degree angle of approach.

Alexei required weekly adjustments of his flexion outrigger to maintain the 90-degree angle of approach as his MP and PIP flexion increased. As his finger flexibility and functional hand motion improved, he was able to lessen time spent in the splint.

Splint Classifications

Splints may be described in various ways. Terminology varies, and it is useful to understand some of the ways that splints may be described. For purposes of clarity, splint classifications are described here according to type, purpose, and design.

One reference to be considered when classification is discussed is the Splint Classification System (SCS),1 as published by The American Society of Hand Therapists (ASHT). The SCS describes splint nomenclature based on the functional requirement of a splint, as well as on the anatomy affected. This nomenclature is quite inclusive of the broad variety of UE splints fabricated by occupational therapists and is suggested for study. However, the widely used terms static, serial static, dynamic, and static progressive are not included in the SCS. These splint choices are noted under “Common Names.” An excellent summary of the Splint Classification System can be found in Jacobs and Austin’s “Splinting the Hand and Upper Extremity, Principles and Process” (Chapter 1).15

Splints Classified by Type

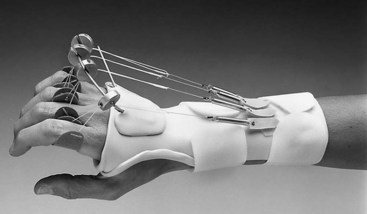

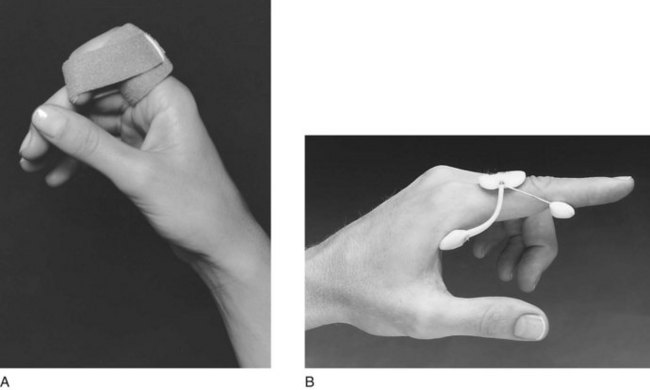

Dynamic splints include one or more resilient components (elastics, rubber bands, or springs) that produce motion. The force applied from the resilient component is constant even when tissues have reached end range. Dynamic splints are designed to increase passive motion, to augment active motion by assisting a joint through its range, or to substitute for lost motion. Dynamic splints generally include a static base on which movable, resilient components can be attached (Figure 30-18). A common use of dynamic splinting is to gain greater finger range of motion by adding dynamic MP extension and/or MP flexion components to a splint. Figure 30-18 shows the type of dynamic splint fabricated for Alexei to gain finger extension. Figure 30-19 shows the type of dynamic splint fabricated for Alexei to gain finger flexion.

FIGURE 30-19 Dynamic splint for finger flexion. (From Fess EE, Gettle KS, Philips CA, et al: Hand and upper extremity splinting: principles and methods, ed 3, St Louis, 2005, Mosby.)

A static splint has no movable components and immobilizes a joint or part. Static splints are fabricated to rest or protect, to reduce pain, or to prevent muscle shortening or contracture. An example of a static splint is a resting pan splint that maintains the hand in a functional or resting position (Figure 30-20).

FIGURE 30-20 Single-surface static resting splint positions hand in 20-degree to 30-degree wrist extension, 45-degree to 60-degree metacarpophalangeal flexion, and 15-degree to 30-degree proximal interphalangeal and distal interphalangeal flexion.

A serial static splint achieves a slow, progressive increase in ROM by repeated remolding of the splint or cast. The serial static splint has no movable or resilient components, but rather is a static splint whose design and material allow repeated remoldings. Each adjustment repositions the part at the end of the available range to progressively gain passive motion. A cylindrical cast designed to reduce a PIP joint flexion contracture through frequent removal and recasting is a classic example of a serial static splint (Figure 30-21).

FIGURE 30-21 A series of cylindrical plaster casts is made to reduce flexion contracture at proximal interphalangeal joint.

Static progressive splints include a static mechanism that adjusts the amount or angle of traction acting on a part. This mechanism may be a turnbuckle, a cloth strap, nylon line, or a buckle. The static progressive splint is distinguished from the dynamic splint by its lack of a resilient force. It is distinguished from a serial static splint in having a built-in adjustment mechanism, so that the part can be repositioned at end range without the need to remold the splint. Generally, the static progressive mechanism can be adjusted by the client as prescribed or as tolerated (Figure 30-22).

Splints Classified by Purpose

Although nomenclatures may vary, the categories presented in the splint classification system (SCS) describe splints in functional rather than design terms.1 Splints are broadly described first as articular or nonarticular, and then by location and direction. The SCS then is divided into three overriding purposes of splints: restriction, immobilization, and mobilization. The publication also lists many functions of splints, each of which is placed in one of three categories. Splints may fulfill more than one function or purpose, depending upon the method of fabrication and the problems they address.

Restriction Splints: Restriction splints limit joint ROM but do not completely stop joint motion. One example is the splint in Figure 30-23, which blocks PIP joint hyperextension while allowing unlimited PIP joint flexion. Semiflexible splints are available that limit motion at the extremes of range but allow motion in the middle of the range. Although the splint may be restrictive, the goal or function of the splint may vary.

Immobilization Splints: Immobilization splints may be fit for protection to prevent injury, for rest to reduce inflammation or pain, or for positioning to facilitate proper healing after surgery. The classic example is the resting pan splint (see Figure 30-20), which serves two of the three functions. A resting splint fit for a client after a cerebrovascular accident (CVA) positions the wrist and digits to maintain soft tissue length and can protect the desensate hand against damage.

Mobilization Splints: Mobilization splints are designed to increase limited ROM or to restore or augment function. A mobilizing splint may assist a weak muscle or substitute for motion lost because of nerve injury or muscle dysfunction (Figure 30-24). The splint may attempt to balance the pull of unopposed spastic muscles to prevent deformity or joint changes and to assist function. A splint may provide resistance against which a weak muscle can exercise to improve its strength or to facilitate tendon gliding after tendon surgery. Frequently, mobilizing splints are used to increase the ROM of contracted joints, as in the case of Alexei, who experienced severe finger stiffness as a result of edema, which pooled in his hand after his forearm fracture.

Splints Classified by Design

After the purpose of the splint has been determined, the next decision relates to its design. Each of the types of splints described earlier (static, dynamic, serial static, and static progressive) may be fabricated as a single-surface design, a circumferential design, or a three-point design. A final category, the loop design, is generally limited to acting on finger IP joints by providing a loop of material that wraps around the joints to restore the final degrees of joint flexion.

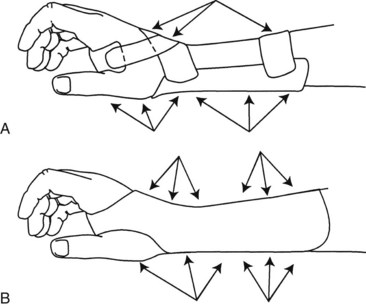

All splints are designed to provide some degree of force. This force may be distributed as a continuous loop, with equal and opposing forces wrapping around two or more joints (Figure 30-25, A). More commonly, the force is applied through three points of pressure (Figure 30-25, B). Although the loop design generally is used only on finger IP joints, some variation of the three-point pressure design is used in all other splints.

FIGURE 30-25 A, Final flexion strap designed to restore full interphalangeal joint flexion provides equal force on all surfaces of the digit. B, Three-point pressure splint with spring wire reduces proximal interphalangeal joint flexion contractures of 35 degrees or less.

Three-point finger splints that incorporate springs, spring wire, or elastics are often used to correct DIP and PIP joint flexion contractures. A flexion contracture exists when a joint will not move passively out of a closed position into extension. These designs include two points of pressure—one proximal to the joint and one distal—and the third or central opposing force, acting directly over or close to the joint, as in Figure 30-25, B. In a three-point finger splint, the force of the central point is equal to the sum of the two forces of the correcting points. This fact is clinically important because tissue tolerance under this central point may be insufficient and may react with pain and inflammation. This problem is seen frequently at the PIP joint, where limited surface area exists over which to distribute pressure. Pressure must be distributed with contoured surfaces that are as broad as possible, and the spring or elastic force and the wearing time must be adjusted to the client’s tolerance. Proper padding incorporated into the splint can aid in distributing pressure.

The dynamic finger-based three-point splint just described is a unique design that does not adhere to the 90-degree rule, that is, when the splint is applied to a joint with a flexion contracture, the angle of approach of the line of traction is never 90 degrees. The more severe the contracture, the greater the translational force that is present; therefore, it is less effective than a properly contoured outrigger splint that adheres to the 90-degree rule. This design should be fitted only in the presence of IP joint flexion contractures of 35 degrees or less. For finger contractures in excess of 35 degrees, a hand- or forearm-based outrigger splint is recommended because it can be positioned to apply force at a 90-degree angle of attack. Alternatively, a conforming, serial static splint can be used, as described in the section on traction.

Single-Surface or Circumferential Design: If a molded splint is to be fabricated, the next decision is whether to use a circumferential or single-surface design. Single-surface splints are fabricated to cover only one surface—the volar or dorsal surface of a limb, or the ulnar or radial half of the hand or forearm. Straps are added to create the three points of pressure necessary to secure the splint (Figure 30-26, A).

FIGURE 30-26 A, Single-surface splint requires properly placed straps to create three-point pressure systems to secure splint and ensure distribution of pressure. B, Circumferential splints create multiple three-point pressure systems to secure splint for immobilization.

Circumferential splints wrap around a part, covering all surfaces with equal amounts of pressure (Figure 30-26, B). Straps are used solely to close the splint or to create an overlap. Thinner materials can be used in molding a circumferential splint, because increased contours in the material add to the rigidity of the splint. An example of added strength from contours is corrugated paper. Consequently, circumferential splints can be made lighter and out of highly perforated materials for air circulation without sacrifice of control.

Indications for Single-Surface Splinting: Single-surface splinting is effective for supporting joints surrounded by weak or flaccid muscles, for instance, following a CVA or peripheral nerve injury. Because little or no active motion is available, the extra control given by circumferential splinting is not needed, and donning and doffing the splint will be easier. A single-surface splint is also effective as the base for attaching outriggers in dynamic splinting, and for postoperative splints in which fabrication of a circumferential splint may damage repaired structures.

Indications for Circumferential Splinting: Circumferential splinting is effective for immobilizing painful joints or for protecting soft tissue (see Figure 30-25, B). Because the circumferential design gives comfortable, complete control, it is particularly helpful when the client will be wearing the splint during activity, when shear forces can be a problem. This comfortable, complete control also makes a circumferential design useful for serial static splints used to reduce contractures. The control that a circumferential design supplies makes it a good design for stabilizing proximal joints when outriggers are applied to act on more distal joints.

When to Splint and When Not to Splint

A first step in deciding which splint style and design to choose is to determine whether the client is a good candidate for wearing a splint. Several issues should be examined in this regard.

Compliance Issues

First, the therapist must consider whether or not the client is likely to comply with the splinting program. The splint may have a negative effect on the client’s ability to be independent in self-care or to function at work. Some clients are sensitive about their appearance and may refuse to wear a splint if it offends their aesthetic sense or negatively affects their body image. Compliance with a splinting program may be poor if the client’s general level of motivation to get better is low. On the other hand, some clients are so highly motivated that they will overdo the splinting program and cause themselves damage. Finally, the client’s cognitive and perceptual ability to follow a splinting program should be considered, especially if no responsible care provider is available to supervise the splint-wearing precautions.

Ability to Don and Doff a Splint

Even if compliance is not an issue, the client may have problems donning and doffing (putting on and removing) the splint. For example, the client may have no one at home to assist in donning and doffing a difficult splint. The hospitalized client may not have adequate staff help to follow the wearing schedule or to apply the splint correctly.

Skin Tolerance and Hypersensitivity

The therapist must assess the skin condition of the client before deciding to fit a splint. Clients who experience diaphoresis and produce excessive perspiration that may lead to skin maceration need to be evaluated more carefully for splint consideration and type, such as ventilated plastics and absorbent padding. Some clients are intolerant of any pressure because of extremely fragile skin or sensory dysfunction. If these issues arise and cannot be ameliorated, safe alternative therapeutic interventions must be substituted for the splint.

Wearing Schedule

If none of the preceding issues prevents the client from being a candidate for splinting, the therapist must decide on the optimum wearing schedule for the splint. Nighttime may be the best time for a client to wear a static splint designed to change ROM. It is also the time when clients need resting splints to prevent them from sleeping in positions that may damage the hand or allow nerve compression. During the daytime, the client may wear a dynamic splint or a splint designed to assist function. It is often best to minimize splinting during the day if possible, so that the client can use his or her hand as normally as possible. For some who must wear positioning hand splints at night, it may be advisable to alternate wearing splints on one hand at a time so that the individual is not left without the sensory input and function of a splint-free hand. Such a splint-wearing schedule, although not ideal for meeting therapeutic goals, may at least offer a compromise for better compliance.

Splint Fabrication Process

Once the decision has been reached to fabricate a splint, arguably the most important step in the fabrication process is deciding on and creating a pattern. Although it may seem elementary even to the novice splint maker, this step can determine the success of the splint in terms of fit and function. Allowing the time to make a well thought-out and properly fitted pattern gives the splint maker the chance to deal with such issues as what he or she is trying to accomplish with the splint and how the splint is going to fit. Ultimately a properly fitted pattern will make the entire fabrication process easier and faster and will increase the chance of success.

The common technique of making a pattern starts with a tracing or outline of the hand. This generally is taken with the hand lying flat when possible, or by tracing the uninvolved hand if necessary. An amount is added to this outline to approximate the width and length needed for the splint. A common error in this technique is not taking into account the position in which the hand (or other body part) will ultimately be held in the splint.

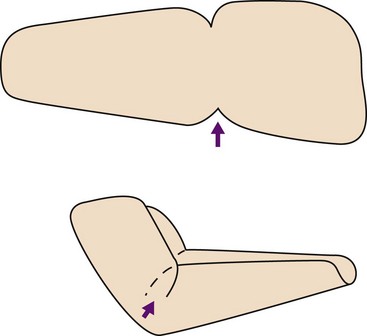

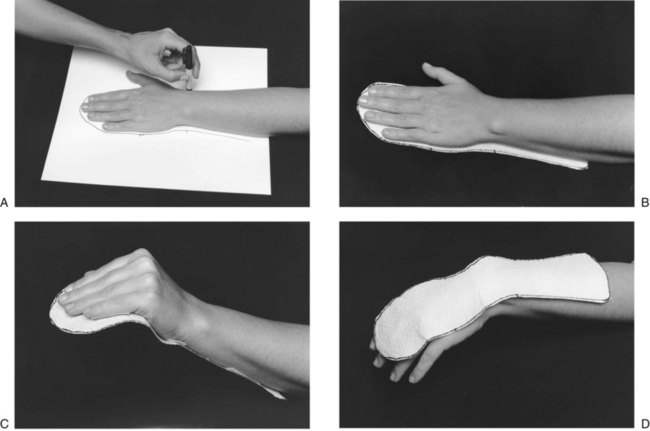

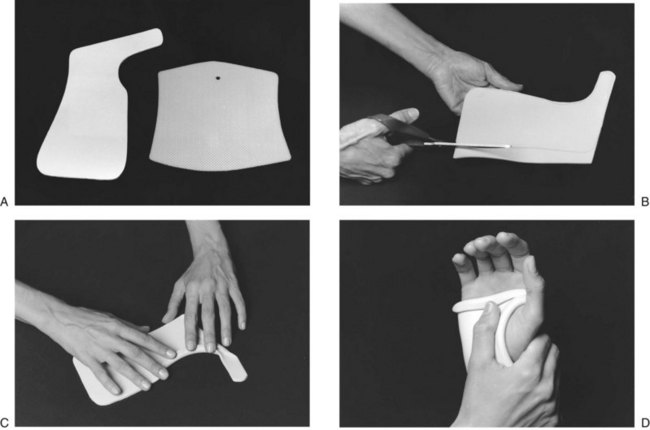

Figure 30-27, A and B, shows a pattern taken with the hand lying flat, with no length added to the pattern. In Figure 30-27, C, when the pattern is fit on the volar surface of the hand with the hand in functional position (the wrist in 35 degrees of extension, the MP joints at 70 degrees of flexion, and the IP joints in 10 to 20 degrees of flexion), the pattern extends beyond the fingertips and in fact is too long. The same pattern on the dorsum of the hand (Figure 30-27, D) with the wrist now in flexion illustrates that the pattern is now too short. Going from the volar surface of the hand to the dorsal surface is akin to driving around the inside of a curve as opposed to the outside of a curve. As any race car driver knows, the inside of a curve is the shorter distance. Altering the position of the hand and the surface to which the splint will be fit alters the length of the pattern. The splint maker must accommodate for this by checking the splint pattern on the hand in the position in which the hand will be splinted.

FIGURE 30-27 A, Tracing with pencil perpendicular to the arm creates a true size pattern. B, Pattern is full length with hand flat. C, Pattern is too long when fit on the volar surface with hand in resting position. D, Pattern is too short when fit on dorsum of hand with wrist and fingers in flexion.

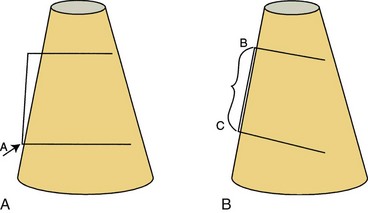

Depth is the second dimension that must be considered when a pattern is made. The ideal trim lines of a single-surface splint fall at midline along the arm, hand, leg, or foot. A splint trimmed at midline provides optimal support and allows for proper strapping to help secure the splint in place (Figure 30-28).

FIGURE 30-28 Forearm trim lines. A, Trim lines are too high, extending above forearm. Straps will bridge arm and will be ineffective. B, Trim lines are too low. Straps cannot substitute for too-low trim lines without applying excessive pressure. C, Midline trim lines ensure that straps properly secure splint on arm and hand.

To determine how much to add to the outline to achieve midline trim lines, the maker must observe the width and depth of the arm or hand. The forearm is cone-shaped, not a straight cylinder, and it graduates in depth over the forearm muscle. Even the thinnest forearm graduates in width and depth proximally. Persons with significant muscle bulk may have graduation at quite an acute angle from the wrist to the proximal forearm. Determination of how much to add to a forearm trough must consider how much the splint must come out, around, and up the forearm to reach midline. The depth of the hand, particularly the depth of the hypothenar eminence, must be known to create the proper trim lines for a hand platform.

In the fit of any forearm-based splint, the proximal trim lines must take advantage of the soft muscle bellies that protect the radius and the ulna. The proximal borders of the splint should be flared so that the trim line remains at midline to help secure the splint in place on the arm (Figure 30-29).

FIGURE 30-29 A, Narrowing the proximal pattern will cause trim lines to drop below midline. B, Flaring the proximal border of the splint maintains trim lines at midline.

A forearm-based splint should extend approximately two thirds of the length of the forearm, as measured from the wrist proximally. A good rule to remember is to bend the client’s elbow fully and mark where the forearm and the biceps muscle meet. The splint should be trimmed one-quarter inch below this point to avoid limiting elbow flexion, and to prevent the splint from being pushed distally when the elbow is flexed (Figure 30-30).

FIGURE 30-30 Length of forearm-based splint is checked by flexing elbow and noting where biceps meets forearm. Splint is trimmed  to

to  inch distal to point of contact.

inch distal to point of contact.

Most low-temperature thermoplastics used to make splints will stretch to conform around angles and contours. When a pattern is created that will go around an acute angle, such as a 90-degree angle around a flexed elbow or wrist, the pattern should include a dart, where the material can be overlapped without causing undue bulk (Figure 30-31). The pattern may be angled where necessary to accommodate acute angles. A well-fit and well-thought-out pattern translates to less material wasted, less expense, and shorter fabrication time.

Step Two: Choosing Appropriate Material

The materials commonly used for custom-fabricated splints are those in a family of plastic polymers that become pliable at a temperature low enough for the material to be molded directly onto the skin. The low-temperature thermoplastics (LTTs) currently available have certain characteristics that can be defined according to how a material reacts or handles when warm, and how it reacts once molded.

Choosing the optimal material for a given splint application can make the difference between a quick and easy splint-making process and one that requires extensive adjustments and reheating. It behooves every splint maker, novice to advanced, to sample a variety of materials and test the handling characteristics, so that no surprises occur when a material is heated and is ready to be cut and fitted to a client.

Characteristics of Splint Materials: Each LTT has some handling characteristics that apply when the materials are warm and pliable, and others that apply when they are cold or molded. Following is a list of the most common characteristics and a description of how each contributes to the choice of a material for a specific application.

Resistance to Stretch: Resistance to stretch describes the extent to which a material resists pulling or stretching. The greater the resistance, the greater is the degree of control that the splint maker will have over the material. Materials that resist stretch tend to hold their shape and thickness while warm and can be handled more aggressively without thinning. More resistant materials are recommended for large splints and for splints made for persons who are unable to cooperate in the fabrication process. In contrast, the less resistance to stretch a material has, the more the material is likely to thin during the fabrication process, and the more delicately it must be handled. The advantage of stretch is seen in the greater degree of conformability attained with less effort on the part of the splint maker.

Conformability or Drape: Resistance to stretch and conformability or drape describe nearly the same characteristic, that is, if a material stretches easily, it will have better drape and conformability. The great advantage of materials with a high degree of drape or conformability is that with a light, controlled touch or simply the pull of gravity, they readily conform around a part for a precise fit. The disadvantage of materials with a high degree of drape (and generally also low resistance to stretch) is that they tolerate only minimal handling, and care must be taken to prevent overstretching and fingerprints in the material. Materials with a high degree of drape are not recommended for large splints or for uncooperative clients. They are ideal, however, for splinting postoperative clients when minimal pressure is desired, and for dynamic splint bases, in which conformability secures the splint against migration (movement distally) when components are attached. Materials with a low degree of drape must be handled continuously until the materials are fully cooled to achieve a contoured fit; often they will not conform intimately around small parts such as the fingers.

Memory: Memory is the ability of a material, when reheated, to return to its original, flat shape after it has been stretched and molded. The advantage of high memory in a material is that the splint can be remolded repeatedly without thinning and weakening of the material. Materials with memory require handling throughout the splint-making process because until they are fully cooled and molded, they tend to return to a flat shape. This and the slightly longer cooling time of materials with high memory can be used to advantage with clients who require more aggressive handling to achieve the desired position. Disadvantages of materials with excellent memory are their tendency to return to a flat sheet state when an area is spot heated for adjustment, and their need for longer handling to ensure that they maintain their molded shape until fully cooled.

Rigidity vs. Flexibility: Rigidity and flexibility in cold splint material are terms that describe the amount of resistance a material gives when force is applied to it. A highly rigid material is very resistive to applied force and may, with enough force, break. A highly flexible material bends easily when even small force is applied to it, and it is not apt to break under high stress. Materials are available that fall all along this continuum.

Generally, the thicker a thermoplastic and the more plastic its formula contains, the more rigid the material will be. Thermoplastics come in thicknesses ranging from  inch (3.2 mm) to as thin as

inch (3.2 mm) to as thin as  inch (1.6 mm). Thinner materials and thermoplastics that contain rubber-like polymers in their formula tend to have greater flexibility in their molded state. Flexibility in a material allows for easier donning and doffing of splints and may be desirable for clients unable to tolerate the more unforgiving rigid materials. Rigidity is also a factor of the number and depth of contours included in the design. The same material may yield a semiflexible splint when used to make a single-surface splint with shallow contours, or a rigid splint when used to make a tightly filled circumferential splint.

inch (1.6 mm). Thinner materials and thermoplastics that contain rubber-like polymers in their formula tend to have greater flexibility in their molded state. Flexibility in a material allows for easier donning and doffing of splints and may be desirable for clients unable to tolerate the more unforgiving rigid materials. Rigidity is also a factor of the number and depth of contours included in the design. The same material may yield a semiflexible splint when used to make a single-surface splint with shallow contours, or a rigid splint when used to make a tightly filled circumferential splint.

Bonding: Bonding is the ability of a material to adhere to itself when warmed and pressed together. Many materials are coated to resist accidental bonding and require solvents or surface scraping to remove the coating to bond. Uncoated materials, which require no solvents or scraping, have very strong bonding properties when two warm pieces are pressed together. Self-bonding is helpful when outriggers or overlapping corners are applied to form acute angles, but can be a problem if two pieces adhere accidentally.

Self-sealing Edges: Self-sealing edges are edges that round and seal themselves when heated material is cut. This characteristic produces smooth edges that require no additional finishing, which adds time to the fabrication process. Materials with little or no memory and high conformability generally produce smooth, sealed edges when cut while warm. Materials with memory and those with high resistance to stretch resist sealing, requiring additional finishing.

Soft Splint Materials: Soft, flexible materials such as cotton duck, neoprene, knit elastics, and plastic-impregnated materials may be used alone or in combination with metal or plastic stays to fabricate semiflexible splints. These materials allow fabrication of splints that permit partial motion around a joint, yet still limit or protect the part. Semiflexible splints sometimes are used during sporting activities and to assist clients with chronic pain in returning to functional activity. Semiflexible splints are also used for geriatric clients and for clients with arthritis, who often cannot tolerate rigid splints.

Neoprene splints can be fabricated with the use of sealing glue or iron-on tapes. Careful attention must be given to the patterns for soft splints, because the support they offer relies primarily on achieving a secure fit without gapping or excess material. Most other soft materials require sewing, and the fully equipped OT department should include a sewing machine. A sewing machine is useful for adapting and adjusting prefabricated soft splints to ensure that each splint that leaves the clinic is indeed custom-fit, if not custom-fabricated.

Choosing the Best Category of Material for the Splint: Although an experienced splint maker can make many types of splints from the same material, it is better to choose a material with appropriate handling characteristics for the type of splint being made. The following list can be used as a guide from which to start choosing materials for different applications. The availability of materials and the experience level of the therapist assist in determining the most appropriate material.

Forearm-Based and Hand-Based Splints: Splints need close conformability around a part when they serve as a base for a dynamic splint, stabilize a part of the body, reduce contractures, remodel scar tissue, or immobilize to facilitate healing of an acute condition. Such splints should be made from a material with a high degree of conformability to achieve a conforming fit. When conformability is not crucial, the splint can be made from a material with high resistance to stretch and low to moderate drape. Splints fabricated for burns and other acute trauma do not require as conforming a fit and can be made from low-drape materials. Materials that resist stretch and tolerate aggressive handling are recommended for positioning of a spastic body part, because such materials will not stretch and thin during the splint-making process. Experienced OTs who work without a formal pattern choose a material with a higher degree of drape and conformability and allow gravity to assist in the splinting process.

Large Upper and Lower Extremity Splints: Long splints fabricated for the elbow, shoulder, knee, or ankle generally should be made of materials that have high resistance to stretch, to provide the control necessary for dealing with large pieces of material. Such splints generally do not need to be highly conforming because they are molded over broad expanses of soft tissue. Care must be taken to provide relief for bony prominences, or to provide padding to distribute pressure.

Circumferential Splints: A splint designed to wrap all the way around the part should be fabricated from materials that have a high degree of memory and that tolerate stretching without forming thin spots. The materials should be highly perforated, thin, and able to be stretched evenly. After being stretched, these materials will cinch in around the body part while still allowing sufficient flexibility for easy donning and doffing. These materials work very well for fracture bracing and for circumferential splints that are used for contracture reduction and for stabilizing or immobilizing joints. Another choice for making less restrictive circumferential splints is the use of semiflexible materials, which facilitate easy donning and doffing and allow limited motion within the available arc of motion.

Serial Splints: Serial splints that require frequent remolding to accommodate increases in joint range of motion should be made from a material that has considerable memory or is highly resistant to stretch, to avoid thinning with repeated remolding. The chosen material should have moderate to high rigidity when molded to resist forces from contracted joints or from spastic muscle tone.

Step Three: Choosing the Type of Traction

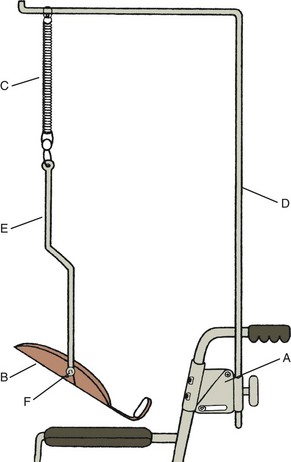

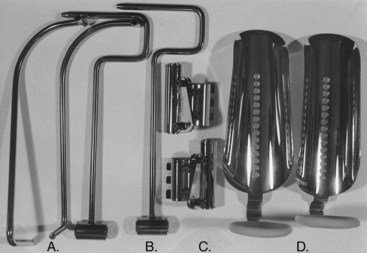

All splints provide some form of traction to move or stabilize a joint or joints. The traction mechanism may be dynamic, using a spring, hinge, or elastic. Traction may also be static, employing straps or turnbuckles or involving remolding of the splint base itself. If the mechanism moves or is resilient, the splint is called a dynamic splint, and if it does not move, the splint is called a static splint. The following section describes the various options for applying traction and discusses appropriate uses of each option.