Prosthetic Applications of Polymers

PROPERTIES OF DENTURE BASE MATERIALS

Poly(methyl methacrylate) polymers were introduced as denture base materials in 1937. Previously, materials such as vulcanite, nitrocellulose, phenol formaldehyde, vinyl plastics, and porcelain were used for denture bases. The acrylic resins were so well received by the dental profession that by 1946, 98% of all denture bases were constructed from methyl methacrylate polymers or copolymers. Other polymers developed since that time include vinyl acrylic, polystyrene, epoxy, nylon, vinyl styrene, polycarbonate, polysulfone-unsaturated polyester, polyurethane, polyvinylacetate-ethylene, hydrophilic polyacrylate, silicones, light-activated urethane dimethacrylate, rubber-reinforced acrylics, and butadiene-reinforced acrylic.

Acrylic polymers have a wide variety of applications in restorative dentistry as denture bases, artificial teeth, denture repair materials, impression trays, provisional restorations, and maxillofacial appliances for skeletal defects. Provisional restorations are discussed in Chapter 9, and impression trays are discussed in Chapter 12.

PROPERTIES OF DENTURE BASE MATERIALS

The following list indicates the requirements for a clinically acceptable denture base material:

2. Satisfactory thermal properties

3. Processing accuracy and dimensional stability

4. Chemical stability (unprocessed as well as processed material)

5. Insolubility in and low sorption of oral fluids

10. Adhesion to plastics, metals, and porcelain

Many commercial materials meet these requirements. The vast majority of dentures made today are fabricated from heat-cured poly(methyl methacrylate) and rubber reinforced poly(methyl methacrylate). Fractures of dentures still occur, but are usually associated with carelessness or unreasonable use by the patient. Considering functional stresses, the oral environment, and expected service life, denture base materials perform remarkably well.

PHYSICAL FORM AND COMPOSITION

Denture base plastics are commonly supplied in a powder-liquid or a gel form. The powder-liquid type may contain the materials listed in Box 21-1.

Powder

Most commercial materials contain poly(methyl methacrylate), modified with small amounts of ethyl, butyl, or other alkyl methacrylates to produce a polymer somewhat more resistant to fracture by impact. The powder also contains an initiator such as benzoyl peroxide (see formula below) or diisobutylazonitrile to initiate the polymerization of the monomer liquid after being added to the powder.

The peroxide initiator may be added to the polymer or be present as a residual from the polymerization reaction and is present in amounts from 0.5% to 1.5%.

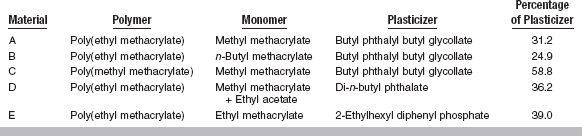

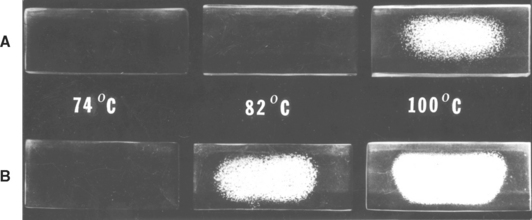

Pure polymers, such as poly(methyl methacrylate), are clear and are adaptable to a wide range of pigmentation. The pigments used to obtain the various tissue-like shades are compounds such as mercuric sulfide, cadmium sulfide, cadmium selenide, ferric oxide, or carbon black, although the use of cadmium salts is suspect because of demonstrated toxicity. These pigments may be locked into the polymer beads by addition during the commercial polymerization, or mechanically mixed with the polymer beads after polymerization, as shown in Fig. 21-1. Generally, the latter method is used, and the uneven distribution of the pigment in the final denture provides a mottled, natural appearance. In addition to coloring agents, zinc or titanium oxides are used as opacifiers, with titanium dioxide being most effective. Dyed synthetic fibers made from nylon or acrylic are usually added to simulate the small capillaries of the oral mucosa.

FIGURE 21-1 Polymer beads with the pigment locked into the polymer, A, and mechanically mixed with the polymer, B (×450). (Courtesy Dentsply International, York, PA.)

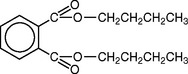

Plasticizers such as dibutyl phthalate may be incorporated in the powder or the monomer. Inorganic particles such as glass fibers and beads or zirconium silicate have been added to plastics. The particles are usually treated with a coupling agent such as an unsaturated triethoxysilane to improve the wetting and bonding of the inorganic particles and the plastic. Studies have reported on the addition of whiskers of alumina, silicon carbide, boron nitride, and carbon fibers to dental plastics. Adding glass fibers and alumina (sapphire) whiskers increases the stiffness, decreases the thermal coefficient of expansion, and increases thermal diffusivity. Polyethylene-woven yarn and polyaramid fabric have also been used to reinforce acrylic polymers.

Most denture bases are radiolucent. Pieces of fractured dentures or temporary acrylic crowns have been aspirated by patients during traumatic injury and are difficult if not impossible to locate. A few denture base materials contain heavy metal compounds of elements such as barium or radiopaque glass fillers added to improve the radiopacity. It is necessary to add up to 20% by weight of these compounds to give sufficient radiopacity, and this results in a reduction in the strength of the material and a change in the appearance of the denture. A 3-year clinical study of a commercial radiopaque polymer, however, showed the dentures performed well and remained radiopaque. Other additives that provide radiopacity include bismuth or uranyl salts at concentrations of 10% to 15% and zirconyl dimethacrylate at 35%. Recently a new radiopaque terpolymer has been synthesized containing [2′3′5′-triodobenzyoyl]-ethyl methacrylate, methyl methacrylate and 2-hydroxyethyl methacrylate. This methacrylate terpolymer may find use as a radiopaque denture base material. It has been shown that esthetically pleasing radiopaque plastics can be made that do not demonstrate cytotoxicity or mutagenicity and have reasonable properties for prosthetic applications. In the future, efforts must be made to improve the handling properties, flexural deflection, and water sorption of radiopaque denture base materials.

Liquid

The liquid component of the powder-liquid type acrylic resin is methyl methacrylate, but it may be modified by the addition of other monomers. Because these monomers may be polymerized by heat, light, or traces of oxygen, inhibitors are added to give the liquid adequate shelf life. The inhibitor most commonly used to prevent premature polymerization is hydroquinone, shown here, which may be present in concentrations of 0.003% to 0.1%.

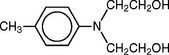

When a chemical accelerator rather than heat is used to speed up the peroxide decomposition and enable the polymerization of the monomer at room temperature, an accelerator is included in the liquid. These accelerators are tertiary amines, sulfinic acids, or the more stable salts of sulfinic acid. Commonly used amines are N,N-dimethyl-para-toluidine, and N,N-dihydroxyethyl-para-toluidine. These systems are referred to as self-curing, cold-curing, or autopolymerizing resins. The pour-type of denture resin is included in this category.

Plasticizers are sometimes added to produce a softer, more resilient polymer. They are generally relatively low-molecular-weight esters, such as dibutyl phthalate. Plasticizer molecules do not enter the polymerization reaction but do interfere with the interaction between polymer molecules. This makes the plasticized polymer softer than the pure polymer. One disadvantage in using plasticizers is that they gradually leach out of the plastic into oral fluids, resulting in hardening of the denture base. A polymer also may be plasticized by the addition of some higher ester such as butyl or octyl methacrylate to methyl methacrylate. The esters polymerize and form a more flexible plastic. This type of internal plasticizing does not leach out in the oral fluids, and the material remains flexible.

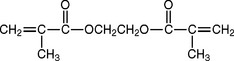

If a cross-linked polymer is desired, organic compounds such as glycol dimethacrylate are added to the monomer. Cross-linking compounds are characterized by reactive —CR=CH— groups at opposite ends of the molecules and serve to link long polymer molecules together. Using cross-linking agents provides greater resistance to minute surface cracking, termed crazing, and may decrease solubility and water sorption. Cross-linking materials may be present in amounts of 2% to 14%, but have little effect on the tensile strength, flexural properties, or hardness of acrylic plastics, although recovery from an indentation by a metal ball such as a Rockwell Superficial Hardness indenter is somewhat improved.

OTHER DENTURE MATERIALS

Several modified poly(methyl methacrylate) materials have been used for denture base applications. These include pour-type denture resins, hydrophilic polyacrylates, high-impact strength resins, rapid heat-polymerized acrylics, and light-activated materials.

Pour-Type Acrylics

The chemical composition of the pour-type denture resins is similar to poly(methyl methacrylate) materials that are polymerized at room temperature. The principal difference is in the size of the polymer powder or beads. The pour-type denture resins, commonly referred to as fluid resins, have much smaller powder particles; when mixed with monomer, the resulting slurry is very fluid. The mix is quickly poured into an agar-hydrocolloid or modified plaster mold and allowed to polymerize under pressure at 0.14 MPa. Centrifugal casting and injection molding are techniques used to inject the slurry into the mold.

High Impact Strength Acrylics

Denture base materials that have greater impact strength have been introduced. These polymers are reinforced with butadiene-styrene rubber. The rubber particles are grafted to methyl methacrylate to bond to the acrylic matrix. These materials are supplied in a powder-liquid form and are processed in the same way as other heat-accelerated methyl methacrylate materials.

Rapid Heat–Polymerized Acrylics

These hybrid acrylics are polymerized in boiling water immediately after being packed into a denture flask. The initiator is formulated from both chemical- and heat-activated initiators to allow rapid polymerization without the porosity one might expect. After placing the denture in boiling water, the water is brought back to a full boil for 20 minutes. After bench cooling to room temperature, the denture is deflasked, trimmed, and polished in the conventional manner.

Light-Activated Resins

This denture base material consists of a urethane dimethacrylate matrix with an acrylic copolymer, microfine silica fillers, and a photo-initiator system. It is supplied in premixed sheets having a claylike consistency. The denture base material is adapted to the cast while it is still pliable. The denture base can be polymerized in a light chamber without teeth and used as a record base. The teeth are processed to the base with additional material and the anatomy is sculptured while the material is still plastic. The acrylic is polymerized in a light chamber with blue light of 400 to 500 nm. The denture rotates in the chamber to provide uniform exposure to the light source. Various formulations of light-activated acrylic are used for many prosthetic applications.

ANSI/ADA SPECIFICATION NO. 12 (ISO 1567) FOR DENTURE BASE RESINS

The scope, requirements, and procedures for evaluating denture base plastics are listed in ANSI/ADA Specification No. 12. The plastics covered by the specification includes acetal, acrylic, carbonate, dimethacrylate acid ester, styrene, sulfone, and vinyl polymers, or mixtures of any of these polymers, as well as copolymers. Categories include the following types and classes:

Type 1—Heat-polymerizable polymers (Class 1, powder and liquid; Class 2, plastic cake)

Type 2—Autopolymerizable polymers (Class 1, powder and liquid; Class 2, powder and liquid pour-type resins)

Type 3—Thermoplastic blank or powder

The specification lists a number of general requirements for the nonprocessed materials. The liquid should be as clear as water and free of extraneous material, and the powder, plastic cake, or precured blank should be free of impurities such as dirt and lint. The specification further states that (1) a satisfactory denture shall result when the manufacturer’s instructions are followed; (2) the denture base should be nonporous and free from surface defects; (3) the cured plastic should take a high gloss when polished; (4) the processed denture should not be toxic to a normal, healthy person; (5) the color should be as specified; (6) the plastic should be translucent; and (7) the cured plastic should not show any bubbles or voids.

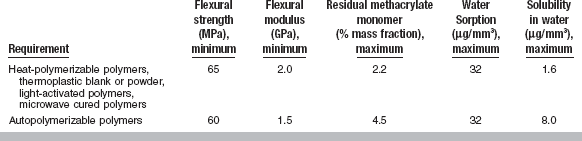

The specific requirements are that (1) within 5 minutes after reaching the proper consistency, indicated by clean separation from the walls of a glass mixing jar, the material shall have adequate flow properties so it will intrude to a depth of at least 0.5 mm into a 0.75-mm-diameter hole when a load of 50 N is placed on a plate 5 mm thick and 50 mm2 in area (this test is modified for pour-type acrylics); (2) water sorption shall not be more than 32 μg/mm3 after immersion for 7 days at 37° C; (3) the solubility shall not be more than 1.6 μg/mm3 for Types 1, 3, 4, and 5 and 8.0 μg/mm3 for Type 2 after the water sorption specimen is dried to constant weight; (4) the plastic shall show no more than a slight color change when exposed 24 hours to a specified ultraviolet lamp test; (5) the flexural strength shall be a minimum of 65 MPa for Types 1, 3, 4, and 5 and 60 MPa for Type 2; (6) the flexural modulus shall be a minimum of 2.0 GPa for Types 1, 3, 4, and 5 and 1.5 GPa for Type 2; and (7) the residual methyl methacrylate monomer shall be a maximum of 2.2% for Types 1, 3, 4, and 5 and 4.5% for Type 2. These properties are summarized in Table 21-1.

PROPERTIES OF DENTAL PLASTICS

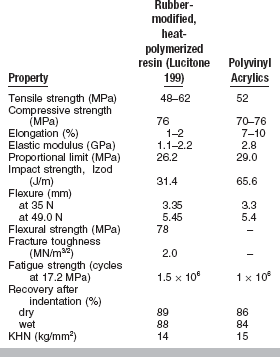

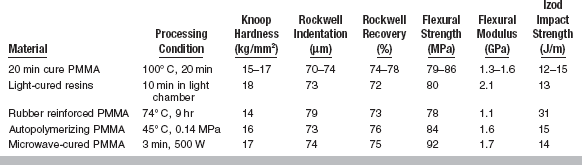

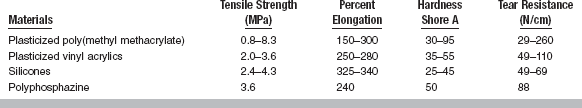

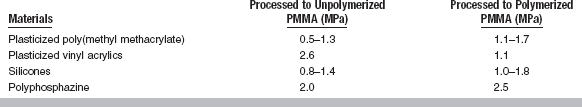

Conventional heat-accelerated acrylic resins are still the predominant denture base materials in use. These materials are typically low in strength, soft and fairly flexible, brittle on impact, and fairly resistant to fatigue failure. The properties of poly(methyl methacrylate) and polyvinyl acrylic are listed in Table 21-2. Several properties of newer denture base materials are listed in Table 21-3.

TABLE 21-2

Properties of Denture Base Polymers

Adapted from Smith LT, Powers JM, Ladd D: Int J Prosthodont 5:315, 1992; Stafford GD, Bates JF, Huggett R et al: J Dent 8:292, 1980.

TABLE 21-3

Mechanical Properties of New Denture Resins

Adapted from Smith LT, Powers JM, Ladd D: Int J Prosthodont 5:315, 1992.

Tensile and Compressive Strength

Table 21-2 reveals small differences between poly(methyl methacrylate) and polyvinyl acrylic. The two acrylics have adequate tensile and compressive strength for complete or removable partial denture applications. Fractures in these materials are usually caused by accidental dropping of a denture or by faulty fabrication. Fractures may also be caused by flexure fatigue from cyclic stresses of low magnitude in service.

Elongation

Elongation, in combination with the ultimate strength, is an indication of the toughness of the plastic. The larger the area under the stress-strain curve, the tougher the material is. Materials having a combination of reasonable tensile strength and elongation will be tough materials, and those with low elongation will be brittle. Examples of tough materials are polyvinylchloride or polyethylene, whereas poly(methyl methacrylate) is more brittle.

Values for percent elongation of polyvinyl acrylics are considerably higher than for poly(methyl methacrylate) and, as expected, the polyvinyl acrylics are tougher and permit larger deformation before fracture.

Proportional Limit

There is some question as to whether dental plastics possess a true proportional limit, because they may be permanently deformed at low stresses, and, as a result, the proportional limit obtained is a function of the rate of stress application. Despite this characteristic, the proportional limit determined under standard conditions is important. A plastic with a low proportional limit will begin to deform permanently at a low stress. If the percent elongation is relatively high, it may deform permanently to a considerable extent before rupture. If the proportional limit is high, considerable stress is required before permanent deformation will occur. A denture material should have a proportional limit sufficiently high that permanent deformation does not result from the stress applied during mastication. Permanent deformation may result in loss of retention or loosening of the teeth embedded in the denture base. The values reported in Table 21-2 for the proportional limit of poly(methyl methacrylates) and polyvinyl acrylics are approximately the same and the dimensional stability of dentures made of these materials would be expected to be similar.

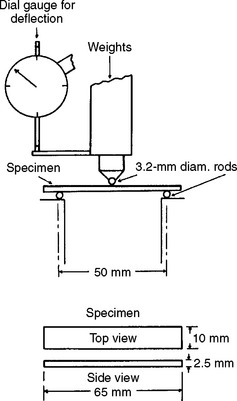

Impact Strength

Impact strength is a measure of the energy absorbed by a material when it is broken by a sudden blow. The impact strength for polyvinyl acrylics is about twice that of poly(methyl methacrylates) (see Table 21-2), which indicates that polyvinyl acrylic absorbs more energy on impact and is more resistant to fracture.

Although the addition of plasticizers may increase the impact strength of plastics, the increases are accompanied by decreases in hardness, proportional limit, elastic modulus, and compressive strength. Ideally, a denture base plastic should have sufficiently high impact strength to prevent breakage on accidental dropping, but not at the expense of the other properties.

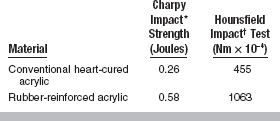

The impact strength of several denture base materials is listed in Tables 21-3 and 21-4. There are differences in relative impact strength with all tests. However, the impact strength of rubber-reinforced acrylic is considerably higher in all instances. When surface defects are present, this improved impact resistance is significantly reduced.

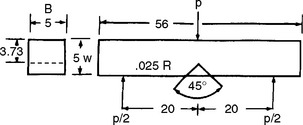

Flexural Strength and Modulus

In the evaluation of denture plastics, flexural strength measurements are used to a greater extent than either tensile or compressive strength, because this test more closely represents the type of loading in vivo. Flexural strength is determined by applying an increasing load until fracture at the center of a test specimen, as shown in Fig. 21-2. The deflection in millimeters at the middle of the plastic specimen is recorded, allowing the flexural modulus to be calculated. As shown in Table 21-3, the flexural strength varies from 78 to 92 MPa and the flexural modulus varies from 1.1 to 2.1 GPa for various denture base resins. When compared with metals used as denture bases, the elastic moduli of all plastics are quite low.

A transverse deflection test was used until the late 1990s to evaluate denture base resins. The requirements were that the deflection in the center of the specimen should be no more than 2.5 mm for a load of 15 to 35 N, and between 2.0 and 5.5 mm for a load of 15 to 50 N. All specimens were tested in water at 37° C after storage in water for 2 days at 37° C.

A comparison of the transverse deflection of several types of materials is seen in Table 21-2. Note that the pour-type acrylic fractured in this test and the rapid heat-cured acrylic was slightly less flexible than the other materials.

Fatigue Strength

Dentures are subjected to a large number of smaller cyclic stresses during mastication. For this reason, the fatigue properties of denture plastics are important. Fatigue strength represents the number of cycles before failure at a certain stress. Values of the fatigue strength at a stress of 17.2 MPa for poly(methyl methacrylates) and polyvinyl acrylic plastics are 1.5 × 106 cycles and 1 × 106 cycles, respectively. Because the current denture base plastics hold up well in service, a value of 1 × 106 cycles at 17.2 MPa is apparently an adequate fatigue strength value.

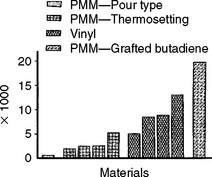

There are many flexural fatigue tests reported in the literature for denture base resins. Results from one of these tests are shown in Fig. 21-3. The specimens were repeatedly flexed under a load of 35.8 N at 342 flexures per minute in a fatigue-testing machine. The flexural fatigue strength of the rubber reinforced acrylic was superior to the other materials, and the pour-type acrylic had the lowest value.

Fracture Toughness

Because the geometry of denture bases is complex and stresses can be concentrated in flaws on the surface or in frenum notches, cracks can occur in the denture base. Several tests are available for determining fracture toughness. One method for testing fracture toughness is to bend a notched specimen and record the force required for crack propagation (Fig. 21-4). Several denture base materials are compared in Table 21-5. The fracture toughness of the high-impact acrylic appears to be no better than that of vinyl or conventional acrylic resin. The rapid heat-cured acrylic had the highest fracture toughness, and the pour-type acrylic the lowest toughness. The fracture toughness of acrylic is greater when specimens are saturated with water rather than dry.

Compressive Creep

When denture base resins are placed under a load they will deform (creep) with time. The lowest compressive creep rates are found for heat-polymerized materials. Chemically accelerated acrylics, both dough and pour-type, have higher values for compressive creep. At low stress levels, the type and quantity of cross-linking agents have no major affect on creep. However, at higher stress levels, creep decreases with increasing quantities of cross-linking agents. For heat-polymerized materials, when the temperature is increased from 37° to 50° C the mode of failure changes from brittle to ductile. For autopolymerizing acrylics, the materials fail in a ductile manner at both temperatures.

Recovery after Indentation

Indentation recovery of plastics in equilibrium with water is generally lower than when dry. The recovery from indentation of a 1.27-cm diameter steel ball loaded for 10 minutes at 30 kg is given in Table 21-2. The time allowed for recovery was 10 minutes. Recovery was 86% to 89% for dry specimens and 84% to 88% for wet specimens. The results for several new products are seen in Table 21-3.

A modified Wallace hardness tester has been used to measure the hardness, creep, and recovery of denture base polymers and the effects of cyclic loading. Results demonstrate the viscoelastic nature of denture base polymers. A torsional pendulum also may be used to evaluate the viscoelastic properties of denture base resins. These tests are useful in evaluating the effect of free monomer, plasticizers, and degree of cross-linking.

Hardness

The low Knoop hardness number of the denture base plastics (see Tables 21-2 and 21-3) indicates these materials may be scratched easily and abraded. Cross-linked poly(methyl methacrylate) is only slightly harder than regular poly(methyl methacrylate) (about 15 kg/mm2). The incorporation of fillers in plastics may alter the resistance to abrasion, but the hardness of the plastic matrix remains unchanged. Polishing, shell blasting, and cleaning denture bases by brushing should be carried out with this in mind.

Abrasion Resistance

Abrasion resistance of denture base resins has been evaluated by abrading specimens against 600-grit silicon carbide paper for 1 hour under a stress of 0.26 MPa in water at 37° C and measuring loss of material (Table 21-6). All materials had similar wear characteristics. However, the vinyl acrylic had the best and the pour-type acrylic had the least wear resistance.

THERMAL CHARACTERISTICS

The thermal properties of acrylics are important because they are usually processed at 74° C and in service are in contact with hot and cold foods and beverages. If a chemical accelerator is used rather than heat, the acrylic is still subjected to exothermic heat resulting from the polymerization reaction.

Thermal Conductivity

Dental plastics are poor thermal and electrical conductors. Compared with gold, cobalt alloys, or even human dentin, which have thermal conductivities of 0.7, 0.16, and 1.3 × 10−3 cal/sec/cm2 (° C/cm), respectively, the values for the various types of plastics listed in Table 21-7 are low. Low thermal conductivity allows plastic denture bases to serve as an insulator between the oral tissues and hot or cold materials placed in the mouth. It has been shown that the inclusion of sapphire whiskers in poly(methyl methacrylate) increases heat conductivity.

Specific Heat

Specific heat, or the heat required to raise the temperature of a gram of plastic 1° C, is a thermal property closely related to thermal conductivity. Although it is not obvious, it may be shown that the ratio of thermal conductivity to the product of specific heat and density is a constant for a particular material and represents the velocity of temperature disturbance in a plastic. The higher this ratio, termed diffusivity, the greater the velocity of heat transfer through a material. The specific heats for poly(methyl methacrylates) and polyvinyl acrylics are similar, and the respective thermal conductivities are not greatly different; therefore, the diffusivity of plastics will be roughly equivalent, 0.123 mm2/sec.

Thermal Coefficient of Expansion

The temperature change from processing temperature to room temperature or mouth temperature indicates the importance of the thermal coefficient of expansion. Plastics have relatively high thermal coefficients of expansion (71 to 81 × 10−6/° C) compared with other dental materials. Gold, amalgam, and tooth structure have values of 14.4 × 10−6/° C, 22 to 28 × 10−6/° C, and 11.4 × 10−6/° C, respectively. The addition of fillers such as glass reduces the thermal coefficient of expansion, although the reduction is not a linear function of the amount of the filler present. Thermal expansion is important in the fit of denture bases. It is apparent that a denture that fits a cast accurately at room temperature will not fit exactly the same at mouth temperature.

Heat Distortion Temperature

Heat distortion temperature is a measure of the ability of a plastic to resist dimensional distortion by heat. This is the temperature at which a specimen flexurally loaded at 1.8 MPa stress deflects a distance of 0.25 mm. These temperatures are sufficiently high that they are of little concern except in the repair of dentures. The heat distortion temperature for polyvinyl acrylic is 54° to 77° C and for poly(methyl methacrylates) 71° to 91° C. These values suggest the need for keeping repair temperatures low by using chemically or light-polymerized materials for this purpose.

Plastics or polymers, when heated, are transformed from a glassy or brittle condition to a rubbery condition. The temperature of this transition is called the glass transition, Tg. Molecular motions are allowed above this temperature that are not per-mitted at lower temperatures, thus plastics are easier to deform above Tg.

OTHER PROPERTIES OF DENTURE POLYMERS

The density, or the weight in grams of a cubic centimeter (g/cm3) of material, varies in plastics because of variations in molecular weight. Denture base plastics have densities ranging from 1.16 to 1.36 g/cm3 (Table 21-8), or slightly greater than the density of water.

TABLE 21-8

Miscellaneous Properties of Poly (Methyl Methacrylate) Denture Base Polymers

| Property | Poly(methyl methacrylates) |

| Density (g/cm3) | 1.16–1.18 |

| Polymerization shrinkage (% by volume) | 6* |

| Dimensional stability | Good |

| Water sorption (mg/cm2; ADA Test) | 0.69 |

| Water solubility (mg/cm2) | 0.02 |

| Resistance to weak acids | Good |

| Resistance to weak bases | Good |

| Effect of organic solvents | Soluble in ketones, esters, and aromatic and chlorinated hydrocarbons |

| Processing ease | Good |

| Adhesion to metal and porcelain | Poor |

| Adhesion to acrylics | Good |

| Colorability | Good |

| Color stability | Yellows very slightly |

| Taste or odor | None |

| Tissue compatibility | Good |

| Shelf life | Powder and liquid, good; gel, fair |

*Monomer shrinkage in mixes with polymer/monomer ratios of approximately 3:1.

Polymerization Shrinkage

The density of methyl methacrylate monomer is only 0.945 g/cm3 at 20° C, compared with 1.16 to 1.18 g/cm3 for poly(methyl methacrylate). This increase in density is mainly accounted for by an approximate 21% decrease in volume of monomer during polymerization. Because the ratio of polymer to monomer used in the preparation of dental poly(methyl methacrylates) and polyvinyl acrylics is usually 3 : 1, the free volumetric shrinkage amounts to about 6%. The light-activated denture base material has low polymerization shrinkage of 3% because higher-molecular-weight oligomers are used.

It should be pointed out that the linear shrinkage values reported in the literature are generally much less than would be expected (Table 21-9) on the basis of the free volumetric shrinkage, because a portion of the polymerization takes place after the plastic has attained a solid condition, resulting in residual stresses in the plastic rather than additional shrinkage. An ideal plastic would be one that had no polymerization shrinkage, but thermal dimensional change would still result from cooling the plastic from molding temperature to room temperature.

Dimensional Stability and Accuracy

The dimensional stability of the denture during processing and in service is important in the fit of the denture and the satisfaction of the patient. In general, if the denture is properly processed, the original fit and the dimensional stability of the various denture base plastics are good. However, excess heat generated during finishing of the denture can easily distort a denture base by releasing residual stresses.

It has been shown that chemically activated denture bases processed by dough molding with a dimensional accuracy of −0.1% were more accurate than heat-activated denture bases at −0.4%. The most accurate dentures were produced using either a chemically activated pour resin processed under pressure at 45° C or a microwave-activated resin. A visible light-activated resin was more accurate than a conventional heat-activated resin. In the past, injection-molded dentures were less accurate than compression-molded materials. Recent studies demonstrate that dentures processed by new injection molding methods are more accurate than standard compression molding. The increase in vertical dimension of occlusion was very small for the injection-molded acrylic when compared with the conventional compression-molded acrylic.

In another report, six different denture base materials were processed by heat, light, or microwave energy. The denture bases were removed from the casts, finished, and polished. After storage in distilled water for 42 days to allow for water sorption, the dentures were placed back on the stone casts on which they were made and ranked for accuracy of fit by five evaluators. Denture bases processed by microwave energy, low heat at 45° C (autopolymerizing acrylics), or visible light fit better than resins processed at either 74° C (conventional acrylics) or 100° C (rapid heat-cured acrylics).

When evaluated in two dimensions, the dimensional stability of denture bases is usually reported at less than 1%. In one study the accuracy of maxillary dentures was measured at six locations from anterior to posterior. For all materials studied, the accuracy was better from the anterior of the denture to the middle of the palate (generally <100 μm) and became worse toward the posterior of the denture. In a recent study of three-dimensional stability of several products, changes ranged from 0.2% to 8.1% in the frontal dimension, and 0.2% to 9% in the lateral dimension. Changes were greatest in the cross-arch dimension.

There are numerous articles in the literature that report conflicting results for accuracy of denture base resins. However, it is encouraging that emphasis is being placed on dimensional accuracy and some of the newer materials appear superior to older products.

Water Sorption and Solubility

The sorption of water also alters the dimensions of acrylic dentures. This change in dimension is, for the most part, reversible and the plastic may go through numerous expansions and contractions when alternately soaked in water and dried. However, repeated wetting and drying of dentures should be avoided by the patient, because irreversible warpage of the denture bases may result. Denture plastics of the same type may vary considerably in water sorption because of the presence of additives. The thickness of the plastic specimen and the type of polymer influence whether equilibrium water sorption will be attained in 24 hours.

Temperature also affects the rate at which water is absorbed, because the diffusion coefficient is increased by a factor of two between room and oral temperature and the equilibrium absorption value does not change.

Denture plastics can be tested for water sorption: a dried plastic disk 50 mm in diameter and 0.5 mm thick is stored in distilled water at 37° C for 7 days, after which the increase in water is determined and the sorption recorded in micrograms per cubic millimeter. In addition, the solubility of the plastic is measured on the same specimen by redrying to constant weight in a desiccator and reweighing to determine the loss in weight in micrograms per cubic millimeter. A denture plastic should have water sorption not more than 32 μg/mm3 after immersion for 7 days at 37° C and solubility not more than 1.6 μg/mm3 for Types 1, 3, 4, and 5 plastics and 8.0 μg/mm3 for Type 2 plastics (see Table 21-1).

Resistance to Acids, Bases, and Organic Solvents

The resistance of denture plastics to water solutions containing weak acids or bases is good to excellent. Denture plastics are quite resistant to organic solvents, with poly(methyl methacrylate) being more resistant than polyvinyl acrylic. Both are soluble in aromatic hydrocarbons, ketones, and esters. Alcohol will cause crazing in certain denture plastics. Ethanol also functions as a plasticizer and can reduce the glass transition temperature. Therefore, solutions containing alcohol should not be used for cleaning or storing dentures. Incorporating ethylene glycol dimethacrylate as a cross-linking agent in denture base resins has little effect on water sorption, but significantly improves solvent resistance.

Adhesion Properties

The adhesion of denture plastics to untreated porcelain or metals is generally poor. As a result, porcelain teeth or combined metal and plastic bases should be designed so that the porcelain or metal is held by mechanical retention. It has been shown that the lack of adhesion between a plastic base and porcelain teeth provides an area in which microorganisms present in the oral fluids may incubate, and this makes maintenance of a clean denture more difficult. This problem can be avoided by the use of plastic teeth, which form a bond with denture base materials or by organosilane treatment of porcelain teeth (although this treatment is not routinely used). The silane coupling agent, γ-methacryloxypropyltrimethoxysilane, provides a bond between the porcelain and the plastic surface. Many studies have demonstrated the effectiveness of bonding denture base resins to partial denture alloys or titanium using the following ingredients alone or in combination: silica blasting, metal etching, silane coupling agents, 4-META adhesive resin, other organic primers such as 10-methacryloxydecyl dihydrogen phosphate.

Esthetics

The esthetic qualities of denture base plastics include such properties as colorability, color stability, taste, and odor. The ability of the plastics to be colored and their compatibility with dyed synthetic fibers for characterization are both good. Color-measuring systems have been used to compare the actual color of denture base resins with the color of gingival tissues. Results indicate that few commercial products actually match the color of the tissue they are replacing. A color stability test requires that a specimen exposed for 24 hours to an ultraviolet light source shall not show more than a slight change in color when compared with an original specimen. One study questioned the stain resistance of the light-activated denture acrylic. Current denture products have no taste or odor when properly processed.

Tissue Compatibility

The tissue compatibility or allergic sensitization of the skin to the components of denture plastics or to processed plastics has been a subject of considerable contention. It may be concluded that completely polymerized poly(methyl methacrylate) or polyvinyl acrylics rarely cause allergic reactions but that methyl methacrylate monomer or other trace components in the monomer may produce an allergic reaction. Dentures prepared by polymerization of methyl methacrylate with a chemical accelerator may have sufficient residual methyl methacrylate monomer present in the finished denture to cause an allergic reaction in patients who are sensitive to methyl methacrylate monomer. This reaction diminishes as residual monomer leaches out of the plastic. Allergic reactions to heat-processed denture base plastics also occur but less often than with chemically accelerated plastics. Again, residual monomer is considered the allergen, and strict adherence to processing instructions recommended by the manufacturer can keep the residual monomer to a minimum. When patients are known to have suffered from an allergic reaction, processing the denture for extended periods (such as 24 versus 8 hours) may be helpful. Residual monomer levels can also be reduced dramatically by processing heat-polymerized poly(methyl methacrylate) in a water bath for 7 hours at 70° C, followed by boiling for 1 hour. Boiling has only a slight effect on the dimensional accuracy of the processed dentures. Vinyl acrylic or light-activated denture base materials are an alternative for those patients who are sensitive to methyl methacrylate monomer.

In one study, 53 patients wearing dentures and suffering from “burning-mouth syndrome” were evaluated for allergies related to various components of denture base plastics. Epicutaneous patch tests were used. Approximately 15 patients demonstrated a positive skin test to one or more of the following: N,N-dimethyl-para-toluidine, hydroquinone, formaldehyde, methyl methacrylate, and p phenylenediamine, as well as several metallic compounds. Pigments also may be toxic. There is one case reported of a patient who had an extensive systemic reaction to dentures. Patch testing was used and the patient had a positive reaction to the pure dye supplied by the manufacturer. The patient had no reaction to the unpigmented acrylic.

Plasticizers are commonly used in fairly high concentrations to lower the glass transition temperature and to decrease brittleness in soft denture liners. Unfortunately, some plasticizers, particularly phthalates, are known toxins; products that contain these materials should be evaluated for biocompatibility. With the demand for safety from health-related products, greater attention will be focused on the tissue compatibility of denture base materials.

The growth of Candida albicans on the surface of dentures is a concern for many denture patients. This organism is associated with denture stomatitis. An in vitro study has demonstrated the effectiveness of chlorhexidine gluconate in eliminating this organism. The chlorhexidine apparently can bind to acrylic surfaces for at least 2 weeks. Treating acrylic with Nystatin, followed by drying, produces similar results. The use of phenolic disinfectants can cause surface damage to denture base resins and is not recommended.

In addition to Candida albicans, many other microorganisms can adhere to denture base acrylics, such as Streptococcus oralis, Bacteroides gingivalis, B. intermedius, and S. sanguis. It is not surprising that many organisms adhere more to rougher surfaces than to those that are highly polished.

Shelf Life

The shelf life, or useful storage time at room temperature, for denture base plastics varies considerably. Acrylics packaged in the powder-liquid form have excellent shelf life, because the powder is almost indefinitely stable and the liquid usually is adequately protected from polymerization during storage by a hydroquinone inhibitor. Vinyl acrylics, packaged as a gel in which the monomer is in contact with the polymer, must be stored at refrigerator temperature (about 2° C) to have a reasonable storage life of 1 to 2 years. The shelf life of light-activated denture base materials has not been reported.

MANIPULATION AND PROCESSING OF DENTURE BASE POLYMERS

As mentioned previously, denture base polymers are supplied in several forms. The techniques used to process these materials into a finished complete or partial denture are briefly described subsequently, as are the justifications for the various procedures presented.

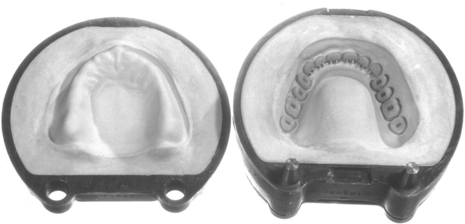

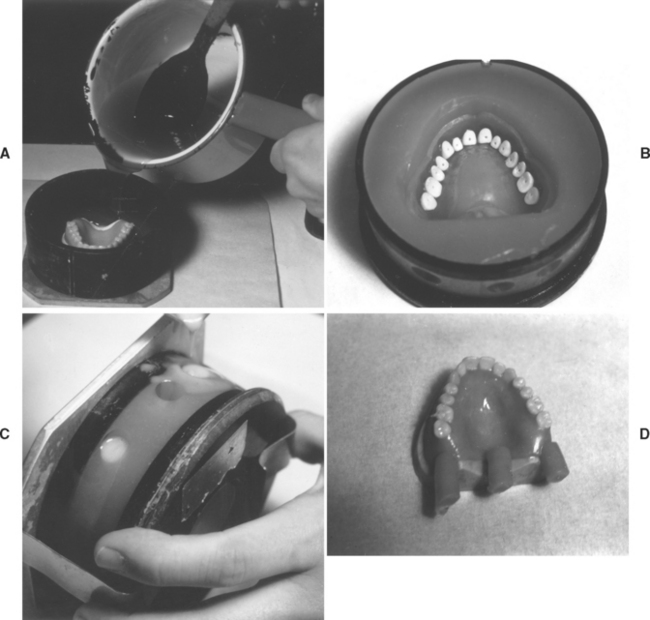

Texts on prosthetic dentistry describe impression techniques, pouring master stone casts, setting denture teeth, preparing the waxed denture, investing in a denture flask, removing the wax, and coating the stone mold to prevent adhesion of the polymer. A set of waxed dentures on stone casts with the teeth in position is shown in Fig. 21-5, and a flask that contains maxillary porcelain teeth ready for packing the acrylic dough is shown in Fig. 21-6.

HEAT-ACCELERATED ACRYLIC DENTURE POLYMERS

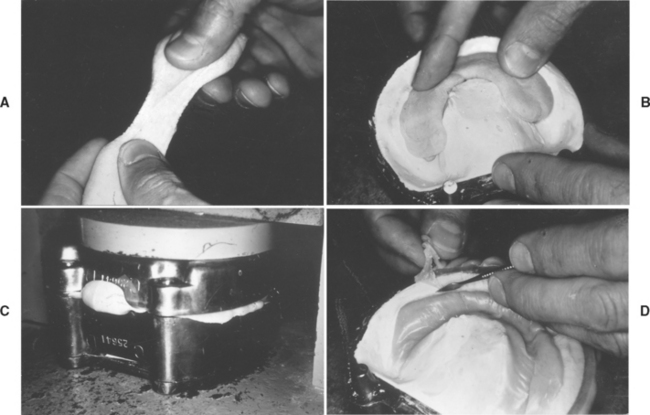

The general method for processing a heataccelerated acrylic denture base material consists of proportioning and mixing the polymer powder and the liquid monomer and allowing the monomer to react physically with the polymer in a sealed jar until a doughy consistency is reached. Before packing, all stone surfaces of the mold are coated with an alginate separator and allowed to dry. The dough is then packed into the treated denture mold containing the artificial teeth and “trial packed” by repeated application of slow pressure with a flask press until no excess flash remains and the material has a glossy surface. Polymerization is accomplished by applying heat and pressure, which are maintained until polymerization is complete. The flask is then bench cooled to room temperature, and the denture is deflasked, finished, and polished.

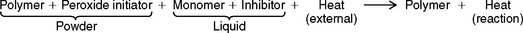

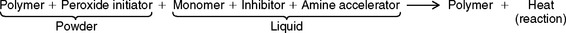

The reaction involved in the heat-accelerated powder-liquid type of acrylic is outlined in a simplified equation here. The powder, consisting of the polymer plus the initiator, and the liquid monomer, containing the inhibitor, are proportioned in the ratio of approximately 3:1 by volume.

Proportioning

There must be sufficient liquid to completely wet the polymer powder. The powder and liquid are mixed with a stainless steel spatula and then kept in the sealed jar during the initial stages of reaction to avoid loss of monomer by evaporation. Incompletely wetted portions can result in a streaked or blanched appearance in the denture because of incomplete polymerization of the polymer during processing. Care should be taken to avoid breathing the monomer vapor. Animal studies have shown that the monomer can affect respiration, cardiac function, and blood pressure.

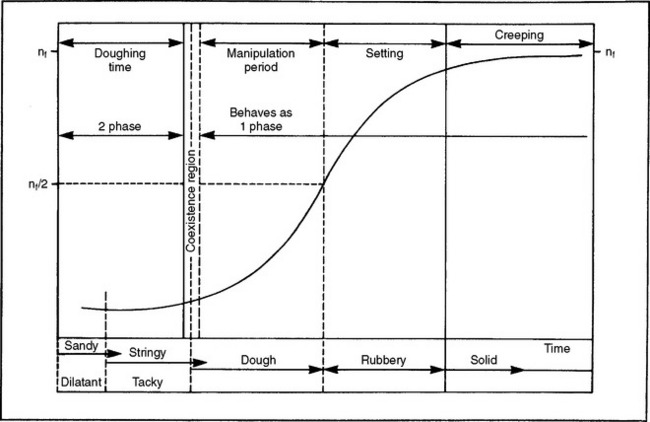

The polymer-monomer mixture, on standing, goes through several distinct consistencies, which may be qualitatively described as (1) sandy, (2) stringy or sticky, (3) doughy or puttylike, (4) rubbery or elastic, and (5) stiff. When the mixture is doughy it has desirable qualities for packing into a denture flask. Different products vary considerably in the time required to reach the doughy condition and the length of time they remain at the packing consistency. These stages or consistencies are represented by a model of the viscosity of the polymer/monomer mix (Fig. 21-7). The symbol nf represents the final viscosity and nf/2 is one half of this value. The powder-liquid mixture of a denture base polymer should be at the packing consistency when the mixture separates cleanly from the walls of the glass mixing jar. This consistency will be attained less than 40 minutes from the start of mixing. The consistency, determined 5 minutes after the packing consistency is reached, should be such that when 5 g of the material are placed over 0.75-mm diameter holes in a brass plate and loaded with a 50-N weight, the dough intrudes into the holes to a depth of not less than 0.5 mm. If the material passes this test, adequate time should be available for trial packing of the denture mold and for final closure. During the various consistency stages, little polymerization is taking place and the reaction occurring is physical in nature. This reaction includes some solution of the polymer in the monomer and some absorption of the monomer by the polymer, as well as wetting of the polymer particles. For conventional acrylic polymers, no substantial polymerization occurs until the denture flask is heated to above 70° C. If too much monomer is used in the mixture, polymerization shrinkage will be greater, additional time will be required to reach the packing consistency, and there will be a tendency for porosity to occur in the denture. If too little monomer is used, the polymer will be insufficiently wetted, the dough will be difficult to manage, and the quality of the final denture will be compromised.

Packing

The powder-liquid mixture should be packed into the flask at the doughy stage (Fig. 21-8, A) for several reasons. If it is packed at the sandy or stringy stages, too much monomer will be present between the polymer particles, the material will be of too low a viscosity to pack well, and it will flow out of the flask too easily. Packing too early may also result in porosity in the final denture base. If packed at the rubbery-to-stiff stage, the material will be too viscous to flow well under the pressure of the flask press, and metal-to-metal contact of the flask halves will not be obtained. Delayed packing will result in loss of detail in the denture, movement or fracture of the teeth, and an increase in the contact vertical dimension of the denture. Some polymers now have increased working time and remain in the doughy stage for periods approaching 1 hour. This permits the packing of several dentures at the same time. Other products, particularly the rubber-reinforced materials, have shorter working times, and in some instances only one or two dentures should be packed with one mix. The polymer dough should not be manipulated excessively with bare hands. The monomer is a good solvent for body oils and may pick up dirt from the hands, resulting in a nonesthetic denture. Monomer may also enter the blood stream through the skin.

FIGURE 21-8 A, Powder-liquid acrylic denture base material in the dough consistency. B, An excess being placed in the mold. C, The excess being forced out between the two portions of the flask. D, The flash being trimmed away. (Adapted from Craig RG, Powers JM, Wataha JC: Dental materials: properties and manipulation, ed 7, St. Louis, 2000, Mosby.)

The acrylic dough is packed into the flask in slight excess by use of a hydraulic, pneumatic, or mechanical press (Fig. 21-8, B), and this excess is removed by trial packing procedures, with a damp cellophane or polyethylene film used as a separator for the upper half of the flask. The film separator allows easy separation of the flask halves during trial packing procedures. The closing force of the press is applied slowly during the trial packing to allow the excess or flash to flow out between the halves of the flask (Fig. 21-8, C). The flask is opened at intervals and the flash trimmed away (Fig. 21-8, D). Before final closure, the separating film is removed and discarded. During final closure of the flask, metal-to-metal contact of the flask halves is completed in the press, the flasks are placed in a flask press that maintains pressure, and the denture is processed.

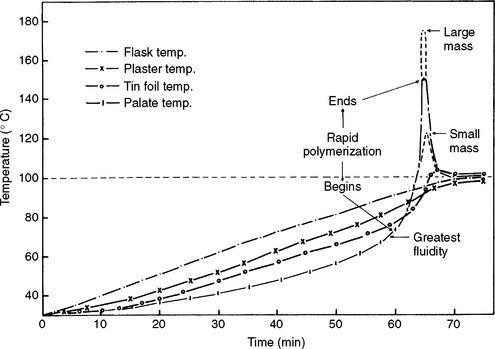

Processing

For heat-polymerized polymers the curing temperature must be maintained close to 74° C, because the polymerization reaction is strongly exothermic. The heat of reaction will be added to the heat used to raise the material to the polymerization temperature. The temperature rise at various positions in a denture flask during a curing cycle is illustrated in Fig. 21-9. The initial temperature increases are in the following order—flask, plaster or stone, tinfoil, and polymer—because the outside of the flask is in contact with the water bath. The temperatures in the different areas increase at approximately the same rate until the temperature of the polymer dough reaches about 70° C. At this point the material becomes quite fluid, and the decomposition rate of the benzoyl peroxide initiator is rapid enough for a substantial amount of polymerization to take place. As the polymerization reaction proceeds, the exothermic heat of reaction increases the temperature of the polymer to values considerably above the surrounding materials and above the boiling point of the methyl methacrylate monomer. This occurs because both the polymer and stone are poor thermal conductors and the heat of reaction is dissipated slowly. Also, the larger the mass or bulk of material, the higher the peak temperature attained in the polymer. In thick sections of a denture the temperature rise will be greater than in thin sections. It has been demonstrated that the strength of thin sections of a denture may be less than that of the thick sections because of a lower degree of polymerization. Because of the excessive temperature rise, porosity will more likely occur in thick sections of the denture.

FIGURE 21-9 Temperature observed at various positions in a denture flask during processing. (Adapted from Tylman SD: J Am Dent Assoc 29:1845, 1942.)

The porosity that developed in two polymers cured at 74°, 82°, and 100° C is shown in Fig. 21-10. Product A showed no porosity at 74° C, a negligible amount at 82° C, and moderate porosity at 100° C. Product B, however, evidenced no porosity at 74° C, a moderate amount at 82° C, and severe porosity at 100° C. On the basis of a large number of studies, a satisfactory processing temperature for most products is between 71° and 77° C, although, as indicated in Fig. 21-10, some products can be processed at higher temperatures without serious difficulty. A satisfactory processing procedure is to cure the polymer in a constant temperature water bath at 74° C for 8 hours or longer. Longer curing times, such as overnight, will not result in any degradation of properties. Another satisfactory processing method, which permits curing in a shorter time, is to heat at 74° C for 1.5 hours and then increase the temperature of the water bath to boiling for an additional hour.

FIGURE 21-10 Effect of the processing temperature on the porosity of two acrylic dental plastics. (From Peyton FA: J Am Dent Assoc 40:525, 1950.)

The porosity shown in the specimens in Fig. 21-10 is in the center. The absence of porosity in the periphery of the specimens results from lower temperatures in these areas because the heat can be dissipated to the surrounding dental stone. The center of the specimens experience higher temperatures because poor thermal conductivity of the polymer prevents the dissipation of heat. Porosity in thick sections of dentures therefore may exist below the surface of the polymer, and in pigmented materials it may not be noticed until grinding or polishing exposes the deeper layers.

Porosity also results when insufficient pressure is maintained on the flask during processing, but the distribution of the porosity is different from that shown in Fig. 21-10. Porosity resulting from insufficient pressure is distributed uniformly throughout the material, rather than concentrated in the center.

Other problems associated with rapid initial heating of the acrylic dough above 74° C are production of internal stresses, warpage of the denture after deflasking, and checking or crazing around the necks of the artificial teeth. High internal stresses resulting from rapid heating combined with the heat of polymerization may be released later and cause distortion and misfit of the denture base.

A variety of other methods of supplying the necessary heat to accelerate the polymerization reaction have been used. They include steam, dry heat supplied by electric platens, dry-air oven, infrared heating, induction or dielectric heating, and microwave radiation. The results of various processing studies have shown that equally satisfactory clinical results may be obtained with any of these methods compared with the water bath method if adequate temperature control and pressure are maintained.

Deflasking and Finishing

After polymerization, the flask is removed from the water bath and allowed to cool to room temperature. If the flask is opened prematurely while the polymer is still warm, warpage is likely to occur. Rapid cooling also tends to increase stresses in the denture, which may be released at a later time. During the cooling process, thermal shrinkage occurs. The thermal shrinkage takes place as a result of the relatively high thermal coefficient of expansion of the polymer. The magnitude of this thermal shrinkage will depend on the difference between the temperature at which the polymer hardens and room or mouth temperature, whichever is the final reference point. It is apparent that as long as the polymer is soft, it will shrink with the stone cast, which has a different thermal coefficient. When the polymer hardens, stresses are induced as cooling continues, because the polymer is forced to follow the shape of the cast despite the differences in thermal coefficients. Deflasking of the denture after cooling, however, allows some of the stresses in the denture to be released, and warpage occurs. Numerous studies dealing with the linear shrinkage of denture bases, measured across the posterior region, have shown that for normal processing conditions, the linear shrinkage is 0.3% to 0.5%. Usually more shrinkage is observed in mandibular than in maxillary dentures because of their shape.

A change in the contact vertical dimension of a denture during processing, as measured on an articulator, is also important. These changes are caused by variations in flask pressure, flask temperature, consistency of the dough, and strength of the stone mold. The pressure developed during closure of the flask is possibly the most important factor. If proper precautions are taken, the vertical opening may be held to 0.5 mm rather than reported variations of 2 to 5 mm.

After cooling, the denture is ejected from the flask and the stone is removed. Stone adhering to the polymer may be removed by shell blasting, a process whereby ground walnut shells are used to abrade the stone with little or no effect on the polymer. After deflasking, the denture is trimmed with an arbor band and acrylic burs and polished. A wet polishing wheel and a slurry of pumice and water should be used to avoid heating the acrylic, which can cause measurable warpage. Tin oxide has been used to produce the final polish. However, tin oxide has been identified as a biological hazard and should be used with caution. After finishing, the denture should be stored in water.

Residual Monomer

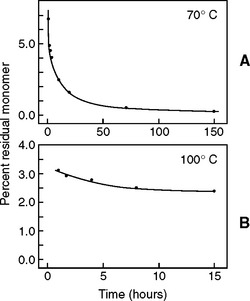

During the polymerization process the amount of residual monomer decreases rapidly at first, then more slowly. The amount of residual monomer in a denture polymer processed at 70° C and at 100° C is shown as a function of the time and processing in Fig. 21-11. At zero time the monomer content was 26.2%. After 1 hour at 70° C it decreased to 6.6%, and at 100° C to 0.31%. After 4 hours the residual monomer was 4.0% and 0.29%, respectively. It required 168 hours at 70° C for the residual monomer to approximate the value obtained after 1 hour at 100° C. These data support the use of a 1-hour terminal boil for processing dentures, as described earlier. However, the processing temperature should not be raised to boiling until most of the polymerization is completed, or porosity may result.

FIGURE 21-11 Residual monomer concentration in the polymerization of methyl methacrylate in dental plastics at 70° C, A, and 100° C, B, as a function of the time of processing. (Adapted from Smith DC: Br Dent J 105:86, 1958.)

The highest residual monomer level is observed with chemically accelerated denture base polymers at 1% to 4% shortly after processing. Storing the denture for several days at elevated temperatures (up to 50° C) and excluding oxygen can significantly reduce the monomer level. However, this may be impractical. The rapid heat-cured denture base materials have significant residual monomer levels from 1% to 3% when they are processed in less than 1 hour in boiling water. If they are processed for 7 hours at 70° C and then boiled for 3 hours, the residual monomer content may be less than 0.4%.

If heat-processed materials are to be used for patients sensitive to residual monomer, processing for longer times in boiling water should reduce the monomer to an acceptable level. Because there is evidence that poly(methyl methacrylate) monomer has poor biocompatibility, every effort should be made to eliminate residual monomer or reduce it to very low levels.

Dimensional Changes

Dimensional changes take place when dentures are stored in water or are in contact with oral fluids. A considerable number of studies have reported on dimensional changes occurring during processing and storage of dentures. The area described with the most uniform results has been the posterior region. In general, heat-cured dentures stored in water show a linear expansion in this region of 0.1% to 0.2%, which partially but not completely compensates for the processing shrinkage of 0.3% to 0.5%. The net linear change can vary from a shrinkage of 0.1% to 0.4%. The major portion of the expansion in water takes place during the first month, and changes are insignificant after 2 months.

In a study comparing the fit of maxillary dentures made from five different commercial products, denture bases were placed on their respective casts after being stored in water at 37° C for 42 days to ensure equilibrium. The materials were ranked from best fit to worst fit by a panel of trained observers. The relative fit was determined by the space between the base and the cast in the palatal region. One rubber-modified acrylic had the worst fit, whereas another had a fit that was similar to the conventional acrylic. The best fit was observed with the vinyl-modified and the hydroxyethyl acrylics. There was no correlation with water sorption values, and therefore the fit of the denture bases may be related more to the glass transition temperature (glassy to brittle transition) than to water sorption for these materials.

There is always concern regarding what a net shrinkage of 0.1% to 0.4% represents clinically. A number of other steps in the preparation of a complete denture may cause dimensional inaccuracies, such as making the impression, pouring the stone cast, and preparing and investing the waxed denture. The oral tissues apparently accommodate small dimensional changes in dentures.

Injection Molding Denture Base Resins

Several manufacturers have reintroduced injection molding materials and equipment and the process is gaining in popularity. The flasking and boiling out of the waxed denture is similar to that used for compression molding. For injection molding, a hollow sprue connects the mold cavity created by wax boilout to an external opening on the flask and a high-pressure injection cylinder is connected to the opening. The denture base resin is mixed and placed in the cylinder. When the material reaches the proper consistency it is injected into the mold cavity under high pressure. The pressure is maintained during the polymerization cycle, and as polymerization shrinkage occurs additional material enters the flask. Several studies have noted increased dimensional accuracy with this technique. Injection molding is also used for microwavable and pour-type acrylics.

CHEMICALLY ACCELERATED ACRYLIC DENTURE POLYMERS—COMPRESSION MOLDING

Chemically accelerated dental polymers, often called chemically curing resins, self-curing resins, cold-curing resins, or autopolymerizing resins, are similar to heat-accelerated dental polymers. The principal difference is that the polymerization reaction is accelerated by a chemical, such as N,N-dihydroxyethyl -para-toluidine, rather than by heat, as indicated by the simplified equation below (compare with the equation given in the earlier section on heat-accelerated acrylic denture polymers).

The amine accelerator reacts with the peroxide initiator at room temperature and sufficient free radicals are produced to initiate the polymerization reaction. Except for initiation, the remainder of the polymerization reaction is the same as for the heat-accelerated type. The reaction is exothermic and polymerization still results in volumetric shrinkage, but the polymer does not reach as high a peak temperature.

Manipulation and Processing

The general procedure for compression molding a chemically accelerated polymer is much the same as for the heat-accelerated type, except after final flask closure the dough is allowed to polymerize at room temperature or in a warm water bath in a pressure vessel.

The denture mold is packed when the polymer-monomer mixture reaches the doughy stage. Several trial closures are made and the flask removed. Care must be taken to make both the trial and final closure before the dough becomes so stiff that final closure is not possible. The chemically accelerated materials start to polymerize soon after the powder and liquid are mixed and proceed more rapidly through the various consistency stages than the heat-accelerated types. The average time needed to reach packing consistency is only 5 minutes for the chemically accelerated type, compared with 15 minutes for the heat-polymerized acrylic. It is more difficult to pack a number of denture flasks from one mix and still obtain complete flask closure. Additional working time may be obtained when the ingredients and the mixing jar are cooled in a refrigerator.

Properties

After the flask is packed it should remain closed and under clamp pressure for a minimum of 2.5 hours to ensure polymerization. Compared with heat-cured polymers, chemically cured types do not reach the same degree of polymerization. The higher residual monomer acts as a plasticizer, which results in higher flexural deflection values and lower flexural strengths. After 15 days in water, however, chemically cured acrylics are nearly as hard as heat-cured. If, after 2.5 hours of curing at room temperature, the flask is boiled for 0.5 to 1 hour, properties comparable to the heat-cured type are obtained, and the residual monomer content is considerably reduced.

Peak temperatures observed at various positions in a denture cured by chemical acceleration are not as high as for heat-polymerized types. The linear shrinkage across the posterior region of a chemically cured maxillary denture after deflasking is about 0.3% compared with 0.5% for a heat-cured maxillary denture. As in the case of heat-cured dentures, mandibular dentures prepared with chemically accelerated denture polymers show more dimensional change than corresponding maxillary dentures. The lower dimensional change of the chemically cured type results because less residual stress is produced in the denture during the processing cycle. This is substantiated by the fact that the chemically accelerated denture polymers produce less shrinkage when processed at 20° to 25° C rather than at 37° C. When chemically cured dentures are placed in water, an increase in the molar-to-molar distance is observed. After 1 month this expansion amounts to about 0.3%, which approximately compensates for the processing shrinkage of 0.3%. Additional storage up to 9 months results in a total expansion of 0.4%, and the net dimensional change at this time is 0.1%, compared with the master model. It should be noted that water sorption of the chemically cured acrylics is about the same as the heat-cured type; however, the solubility is higher for the chemically cured. This higher solubility is caused by the loss of residual monomer from the chemically cured acrylic.

On the basis of these observations, it can be concluded that chemically cured acrylic dentures are generally about 0.1% oversize after several months of service and heat-cured acrylic dentures are 0.3% to 0.4% undersize.

The presence of some amine accelerators may cause problems in color stability. These amines produce colored products on oxidation, and therefore the color stability of chemically cured acrylics may not be as good as that of heat-cured acrylics, although definite improvements have been made since their introduction. Several products are now available that comply with the ANSI/ADA Specification No. 12 color stability test. Activators such as organic sulfinic acids can be used to improve color stability, but these compounds have certain disadvantages, such as chemical instability.

FLUID RESIN ACRYLIC DENTURE POLYMERS

The fluid resin technique takes advantage of the flow properties of polymer-monomer mixtures in the early consistency stage and the smaller size of the polymer powder particles. A very fluid mix also results from a much higher monomer-polymer ratio of about 1:2.5. The polymer and monomer are mixed and then poured into the mold in the denture flask, and no trial packing is required. This procedure is advantageous in the preparation of the saddles for partial dentures, in which trial packing is difficult and flow of polymer around the metal framework is required. It also requires less expensive equipment than the heat-accelerated acrylic. Manufacturers claim that a denture can be produced in much less time using this procedure. This was not substantiated in a laboratory survey.

This technique involves the use of agar or alginate hydrocolloid or, less commonly, a soft stone or silicone mold. The presence of water in the hydrocolloid does not interfere with the polymerization of the slurry of polymer and monomer. The technique involves preparation of a hydrocolloid gel mold of the waxed-up denture, as shown in Fig. 21-12, A. After the gel is formed, the model, including the waxed denture, is removed. The wax is removed from the model and teeth, and the teeth are reinserted into the mold (Fig. 21-12, B). The model is repositioned in the mold after an alginate separator has been applied and allowed to dry. The denture flask is constructed so that two or three circular holes can be cut from the side of the flask through the gel to the posterior portion of the model. A slurry of chemically activated acrylic is poured through one of these holes into the mold space provided by the loss of the wax (Fig. 21-12, C). The remaining hole or holes provide vents for the excess acrylic slurry, thus ensuring adequate filling of the mold space. After pouring the acrylic the flask is placed in a pressure vessel containing warm water, and air pressure of 0.1 to 0.2 MPa is applied. Only 30 to 45 minutes are necessary for polymerization. After processing, the gel is easily broken away from the denture and the denture looks as clean as the one shown in Fig. 21-12, D. Because of higher polymerization shrinkage, dentures fabricated by this technique are slightly less accurate than heat-activated dentures processed in a stone mold. When compared with heat-cured resins, pour-type acrylics are characterized by lower impact and fatigue strengths, higher creep values, lower flexural bend strength, lower water sorption values, and higher solubility. The technique is interesting, because the hydrocolloid mold is easy to prepare, processing time is shortened considerably, the agar hydrocolloid may be reused, problems of broken teeth are eliminated, and deflasking is simplified.

FIGURE 21-12 Slurry casting of chemically accelerated acrylic denture base material. A, Pouring of agar mold. B, Agar mold with denture teeth in position. C, Pouring of powder-liquid slurry into the agar mold. D, Appearance of denture after processing.

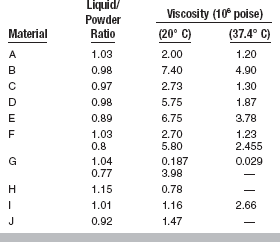

Commercial fluid resins may vary considerably in apparent viscosity. Fig. 21-13 demonstrates the dramatic increase in apparent viscosity of six different fluid resins as a function of time and at a constant shear rate (rotational speed). It illustrates the importance of pouring the fluid resins into the mold soon after the powder and liquid phases are mixed if lower viscosities are to be obtained. The apparent viscosity of fluid resins appears to be an important factor when fluid resin denture materials are evaluated.

LIGHT-CURED DENTURE POLYMERS

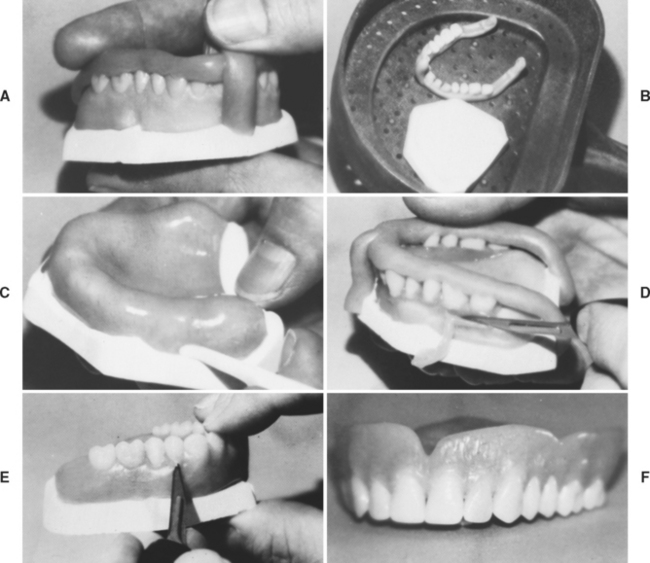

Light curing of a denture is a novel method compared with other processing methods. After the try-in of the waxed-up trial denture is completed, a roll of light-activated acrylic is placed over the occlusal surfaces of the teeth to form a template having three reference areas on the master cast (Fig. 21-14, A). The template is cured in the light chamber for 10 minutes, then the teeth are removed from the trial denture. Removal is simple because the wax softens under the heat of the high-intensity light bulbs. The teeth, the attached template, and the cast are placed in boiling water to remove all traces of wax (Fig. 21-14, B).

FIGURE 21-14 Processing of a light-activated denture base. A, Pick-up of the denture teeth from the waxed trial denture using a rope of the light-activated acrylic. B, Removal of all traces of wax from the teeth and master cast. C, Adaptation of light-activated denture base material to the master cast. D, Reseating the teeth on the master cast and beginning the shaping of the anatomical portion of the denture. E, Final adaptation of the anatomical portion of the denture, just before polymerization in the light chamber. F, Completed light-activated acrylic denture. (Courtesy Dentsply International, York, PA.)

After coating the master cast with a release agent, a sheet of the light-activated denture base material is adapted to the cast and trimmed to the boxing edge (Fig. 21-14, C). The base is then polymerized in the light chamber.

A strip of the light-activated acrylic is placed on the underside of the teeth after they have been coated with a bonding agent. The teeth are then repositioned in the original position on the denture base using the template (Fig. 21-14, D). The teeth are held in position by polymerization in the light chamber.

The anatomical portion of the denture is completed using more of the base material to sculpt the surface and develop the final shape of the denture (Fig. 21-14, E). After contouring, final polymerization is accomplished in the light chamber and the denture is removed from the cast and finished in a conventional manner (Fig. 21-14, F).

FACTORS INVOLVED IN DENTURE RETENTION

Adaptation of the denture base to the oral mucosa has been cited as an important factor in the retention of dentures. Other factors are (1) capillary forces involving the liquid film between the oral tissues and the denture base; (2) surface forces controlling the wetting of the polymer denture base by the saliva; (3) the thickness of the salivary film between the denture and the oral tissues; (4) the surface tension of the saliva; (5) the viscosity of the saliva; and (6) atmospheric pressure. High surface tension, area, and wetting increase retention, as does a thin film of saliva (see Chapter 2). A technical discussion of all factors involved in the retention of dentures is not within the scope of this text.

EFFECT OF AUXILIARY MATERIALS ON DENTURE POLYMERS

A number of materials are used in making and maintaining a denture. These materials may affect the final properties and function of the denture. Examples of such materials are (1) dental plaster and stone, (2) impression materials, (3) wax, (4) mold separators, (5) artificial teeth, (6) characterization materials, (7) repair and reline materials, and (8) denture cleansers.

Plaster and Stone

The strength of the plaster or stone used to invest the wax denture is of concern, because a weak investment resulting from a thin mix or incomplete mixing will not adequately support the artificial teeth during packing of the denture mold. As a result of teeth shifting, the finished dentures may have faulty occlusion. Another problem involved in the use of a stone mold is that the thermal coefficient of expansion, or contraction, is different from the thermal coefficients of the teeth and the polymer used to form the denture. After the polymerization reaction, the polymer and investment cool to room temperature and attempt to contract according to their individual thermal coefficients. The stone cast with a different thermal coefficient creates residual stresses in the acrylic as it cools. These stresses may be released after the processed denture is deflasked and deformation or crazing may result. One study suggests that using a high expansion dental stone in the final impression will compensate for the polymerization shrinkage of the denture base resin and provide greater accuracy in the denture base.

Impression Materials

When alginate materials are used to make an impression, it is important that the cast be poured as soon as possible. If dimensional changes occur in the impression, these inaccuracies will be reflected in the final fit of the denture base.

Waxes

Baseplate wax that is not removed from the crown portion of the teeth before the denture is flasked will cause problems. During the removal of the wax in boiling water, the wax on the coronal area of the teeth is also removed and will result in shifting of the teeth, poor articulation, or broken teeth when the denture is packed. A more common problem is the presence of a residual wax film on the gingival portions of the artificial teeth after the boilout of the wax, which prevents the adherence of the denture base to the teeth. This may be avoided by the addition of detergent to the water used in the boilout procedure, followed by rinsing with clear boiling water.

Mold Separators

Materials such as aqueous solutions of sodium silicate, calcium oleate, or sodium or ammonium alginate are used to facilitate removal of the processed denture from the gypsum cast. The common alginate separators contain about 2% sodium alginate in water with small amounts of glycerin, alcohol, sodium phosphate, and preservatives. Care must be exercised to avoid coating acrylic teeth with these release agents because this will interfere with the bond between the denture base and the teeth.

Characterization Materials

A variety of materials are used for the characterization of dentures. Included in this group of materials are dyed synthetic fibers and pigments. Addition of dyed acrylic fibers to simulate the blood vessels of the oral mucosa does not alter the water sorption or strength of the dental polymer significantly.

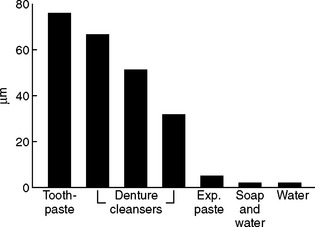

Denture Cleansers

Denture cleansers and cleaning methods may scratch and wear dentures. Denture acrylic has been tested for wear using various commercially available denture cleaning pastes, an experimental paste, soap and water, and water against a reciprocating soft toothbrush. The results shown in Fig. 21-15 are dramatic. The use of water, or soap and water, produced little or no wear compared with the commercial denture cleansers and toothpaste. Daily brushing with a very soft brush (similar to the toothbrushes used in periodontal therapy) is very effective in keeping dentures clean and will not abrade the denture or teeth appreciably if abrasive cleansers are not used. Most immersion denture cleansers are effective in the removal of mucin, stains, and loosely attached food debris. Some immersion cleaners have been demonstrated to be effective sanitizing agents. A water solution containing a hypochlorite and a glassy phosphate (Calgon) is an effective denture cleanser that does not cause discoloration of the dental polymer or the metal retainer pins in porcelain artificial teeth when used occasionally. A solution consisting of 1 tsp of a hypochlorite, such as Clorox, and 2 tsp of Calgon in half a glass of water has been recommended for occasional overnight immersion of acrylic dentures in a glass container. Dentures soaked in this solution must be thoroughly rinsed before use. This cleanser is not recommended for use on prostheses containing cobalt-chromium or nickel-chromium alloys because chlorine solutions tend to darken these metals.

REPAIR MATERIALS

An important application of acrylics in prosthetic dentistry is in the repair of broken dentures. Acrylic repair materials are usually the powder-liquid type, similar to those used for denture bases, and are usually heat-accelerated or chemically accelerated. Light-activated and microwave-cured acrylics have also been shown to be a fast and effective repair materials. The material of choice will depend on the following factors: (1) length of time required for making the repair, (2) flexural strength obtainable with the repair material, and (3) degree to which dimensional accuracy is maintained during repair.

In most cases, when dentures fracture, the pieces can be easily approximated because brittle failure has occurred. If the pieces cannot be realigned and permanent deformation has taken place, it is important to carefully check the adaptation of the denture to the soft tissues. One technique for making a repair requires holding, or luting, the broken pieces together with sticky wax, pouring a stone model on the inside of the denture, and investing the model and denture in a flask. Then the wax is removed, the fracture line is opened with a bur to allow for a reasonable amount of repair acrylic, and the ground surfaces are painted with monomer or a 4 : 1 mixture of monomer and polymer. Acrylic dough is packed into the area being repaired, and the material is cured, cooled, deflasked, and finished.

If a heat-accelerated acrylic is used, the denture should be completely flasked, and curing of the repair material preferably should be carried out at temperatures no greater than 74° to 77° C for 8 hours or longer. This procedure minimizes the dimensional change of the denture base.

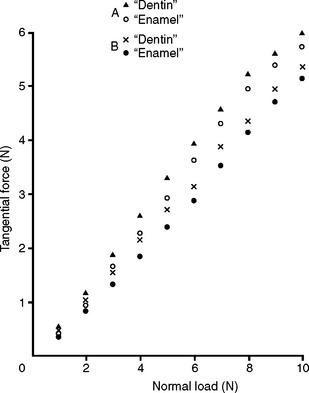

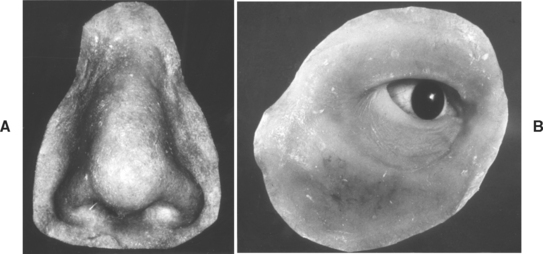

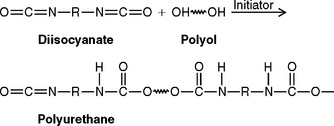

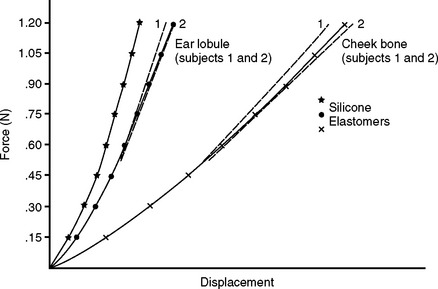

In a similar manner, the repair may be done without flasking, by use of a chemically accelerated acrylic. After a cast is poured, the fracture line is opened and the acrylic is painted into the defect. The denture is then placed in a pressure vessel under air pressure until polymerization is complete. Repairs using light-activated acrylic are done in a similar manner. After the acrylic dough is packed into the defect, curing is done in the light chamber. A bonding agent is used to increase the strength of the repair.