Chapter 21

Tablets

Advantages of Tablet Medication

Disadvantages of Tablet Medication

Types and Uses of Tablets

Granulation

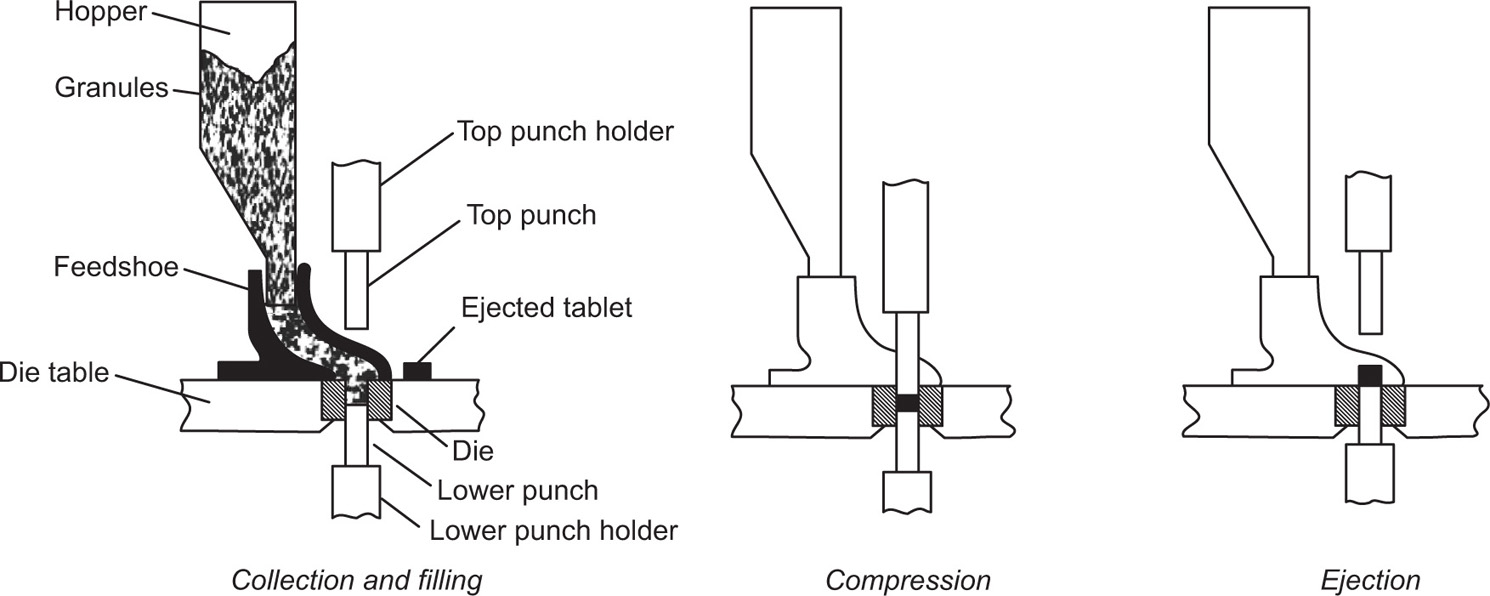

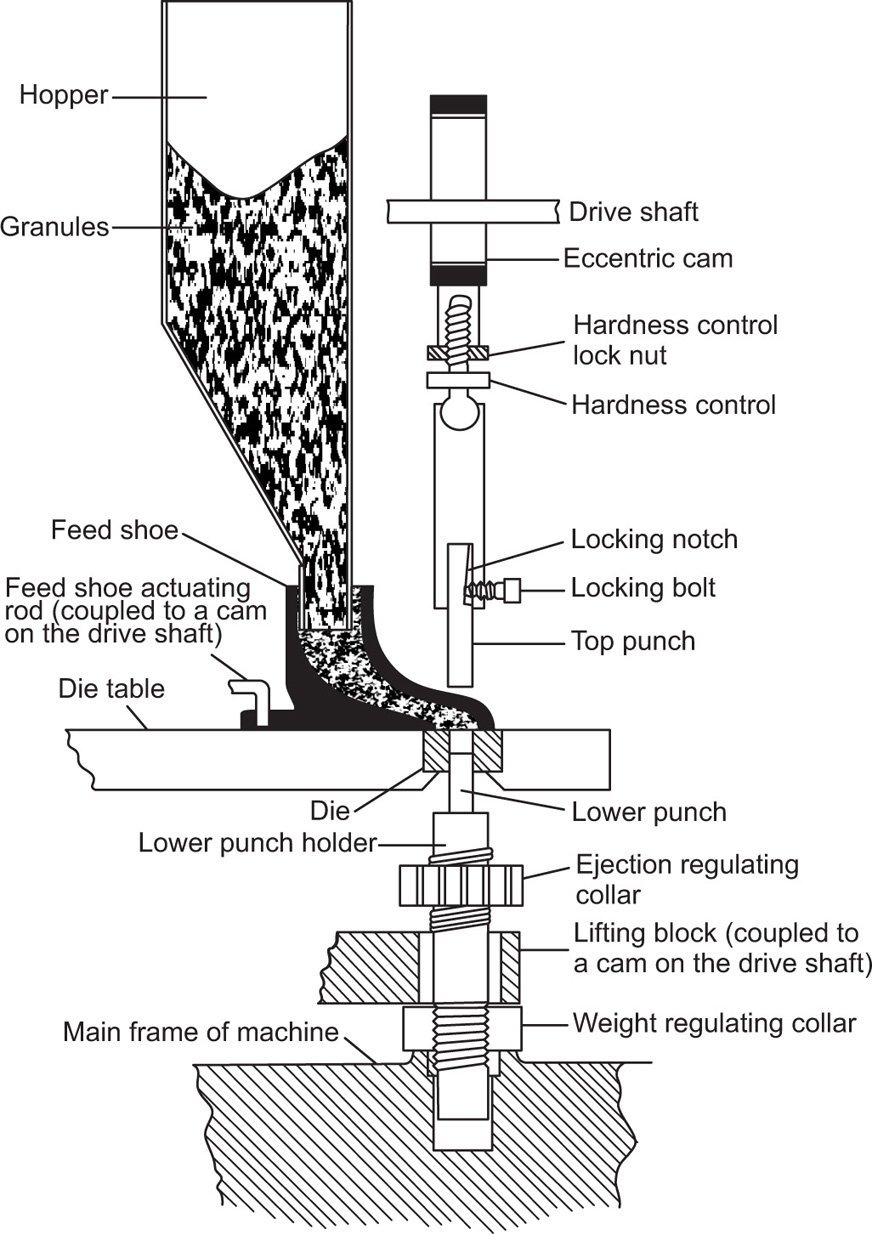

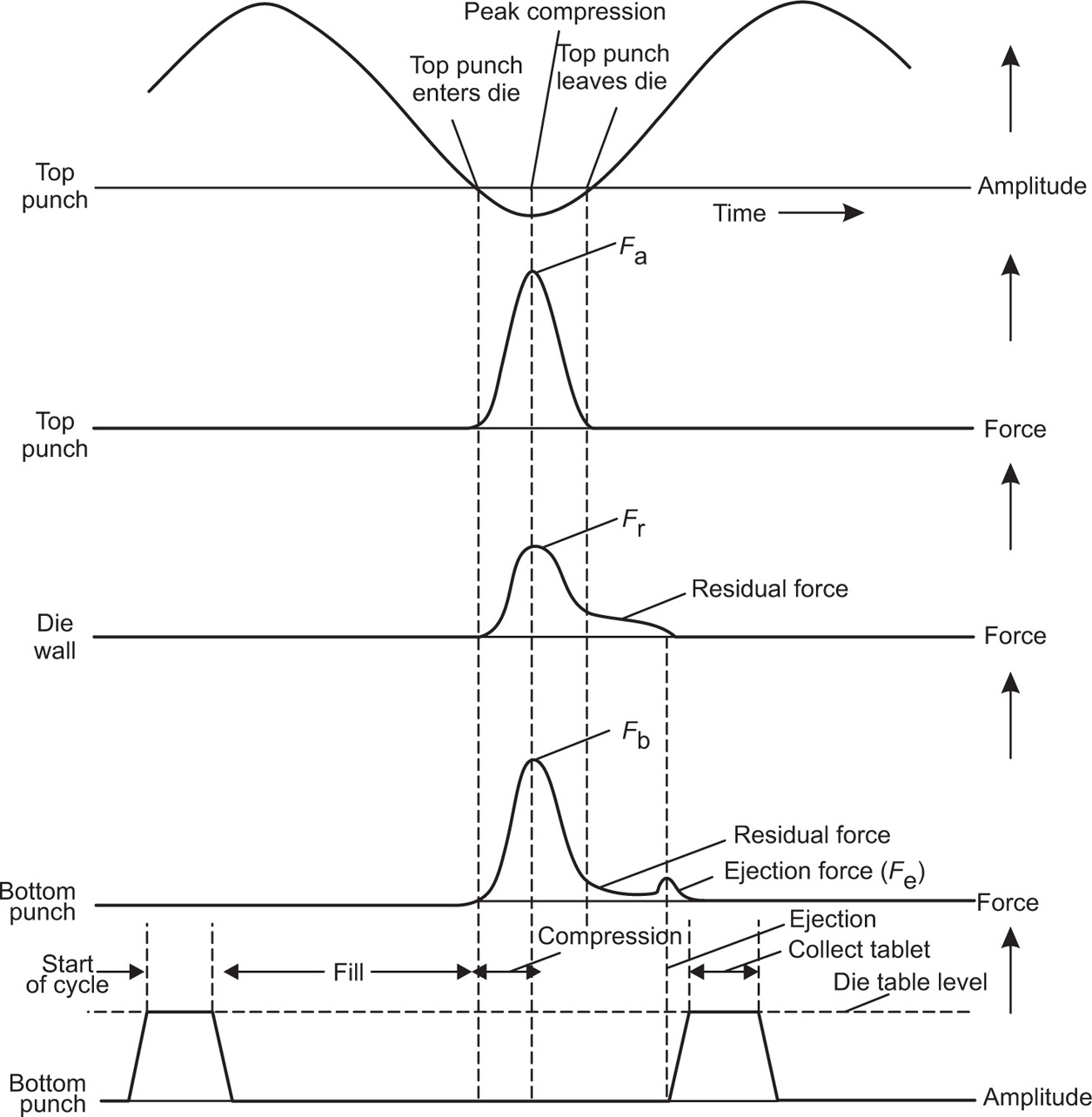

The Tablet Compression Cycle

Fig. 21.1 The compression cycle for a single-punch tablet machine.

Essential Granule Properties

Granulation Processes

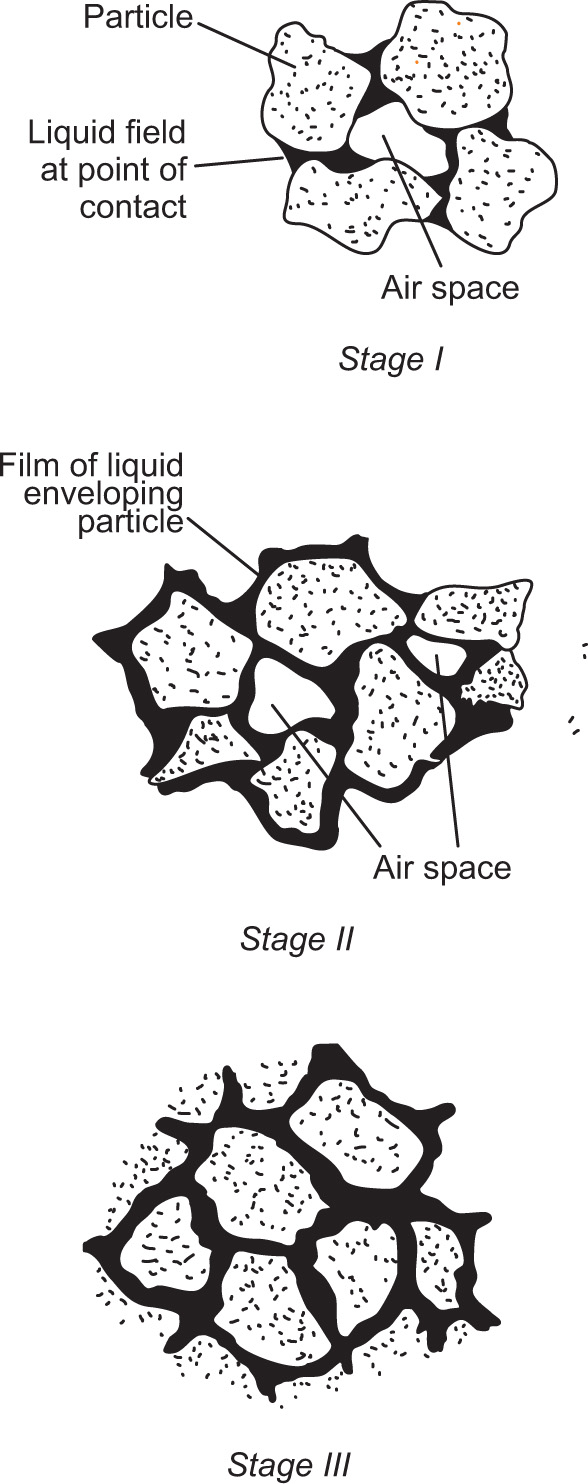

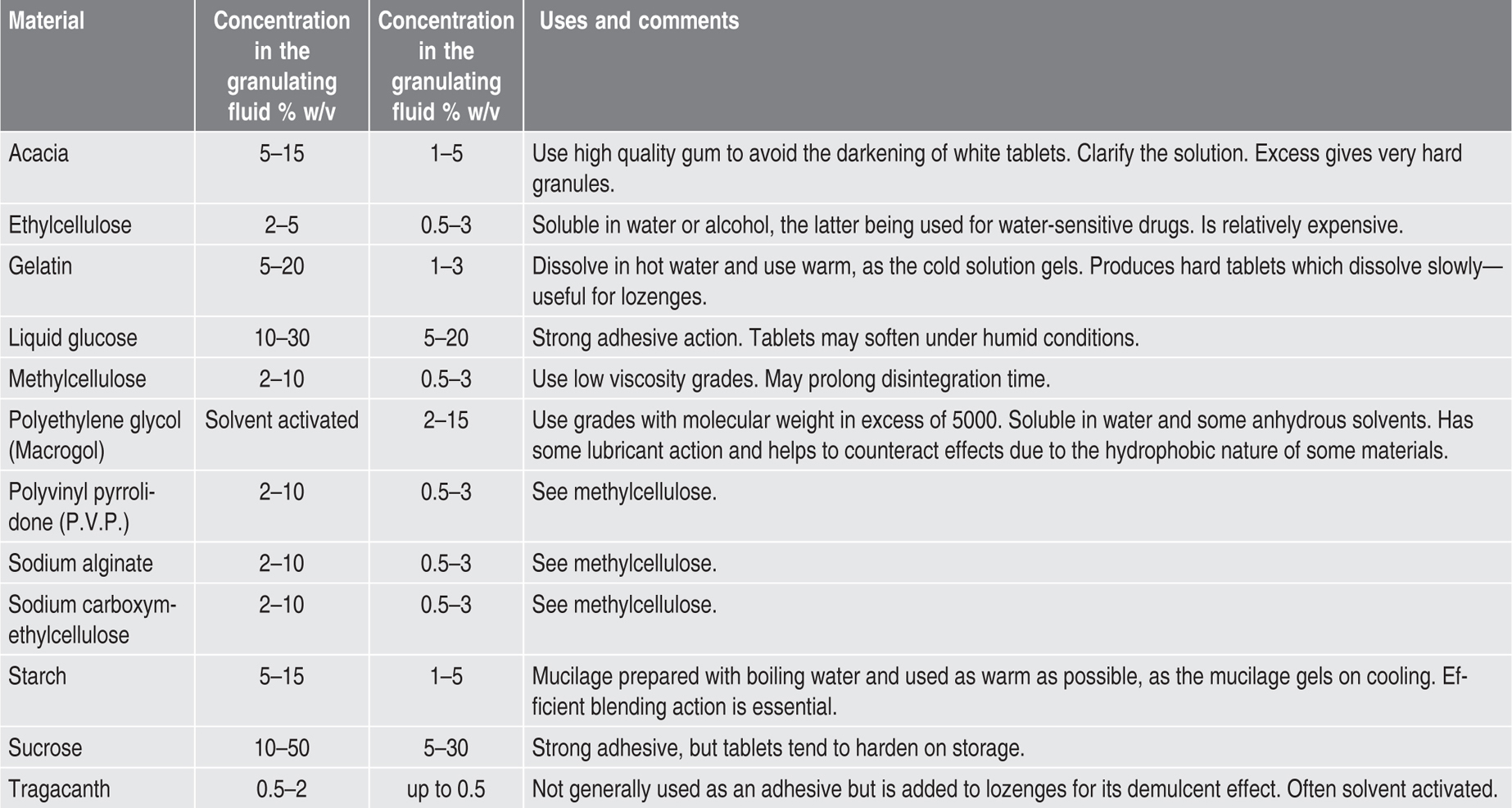

Moist Granulation

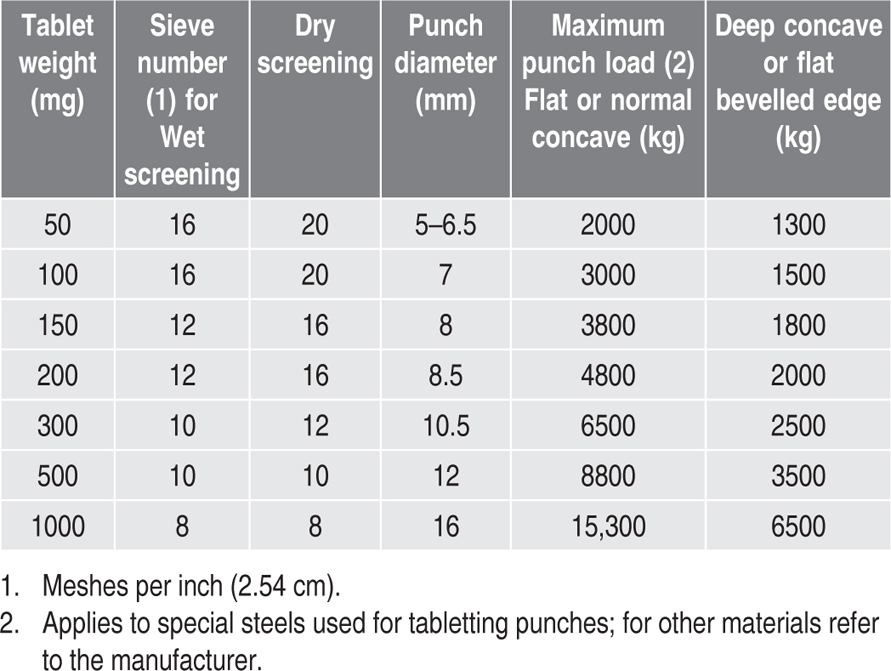

Table 21.1 Some diluents used in tabletting |

|

| Diluent | Uses and comments |

| Calcium Phosphate BPC | Absorbent diluent. Increases granule BPC density but some grades are abrasive. |

| Calcium Hydrogen Phosphate USP | Used for direct compression formulations. |

| Colloidal silica | Small proportion used as an absorbent diluent or to improve granule flow by glidant action. |

| Anhydrous Dextrose BP | Absorbs moisture at high relative humidity—see BPC. |

| Dextrose (spray dried) | Useful for direct compression formulations but absorbs moisture at high relative humidity. |

| Lactose BP | Inert, tasteless, odourless, inexpensive and gives granules by moist granulation which have good tabletting properties. Incompatible with primary amines (Duvall et al., 1965). |

| Lactose (spray dried) | Used for direct compression formulations but tablets may assume a brown tinge on storage (Brownley & Lachman, 1963). Is also incompatible with primary amines. |

| Lactose (anhydrous) | Used for direct compression formulations. Care should be taken to prevent moisture uptake. Is also incompatible with primary amines. |

| Mannitol BP | Dissolves readily and has a ‘cooling’ effect in the mouth. |

| Microcrystalline cellulose | Mainly used for direct compression formulations; has some lubricant and disintegrant effect and may improve the behaviour of granules made by other methods. |

| Sodium Chloride BP | Oral tablets containing this substance must be dissolved in water before administration to avoid gastric irritation—see BP. Usually reserved for the formulation of solution tablets. To avoid binding during compression, dry thoroughly and compress while still Warm. |

| Starch BP | Small proportion of dried starch may be used as an absorbent excipient but its main use is as a disintegrant. |

Fig. 21.2 The Beken change pan mixer with working capacity of about 0.1m3. The machine is shown with the pan lowered and the guard open (Beken Engineering Ltd.).

Fig. 21.3 Stages in the moistening of a powder.

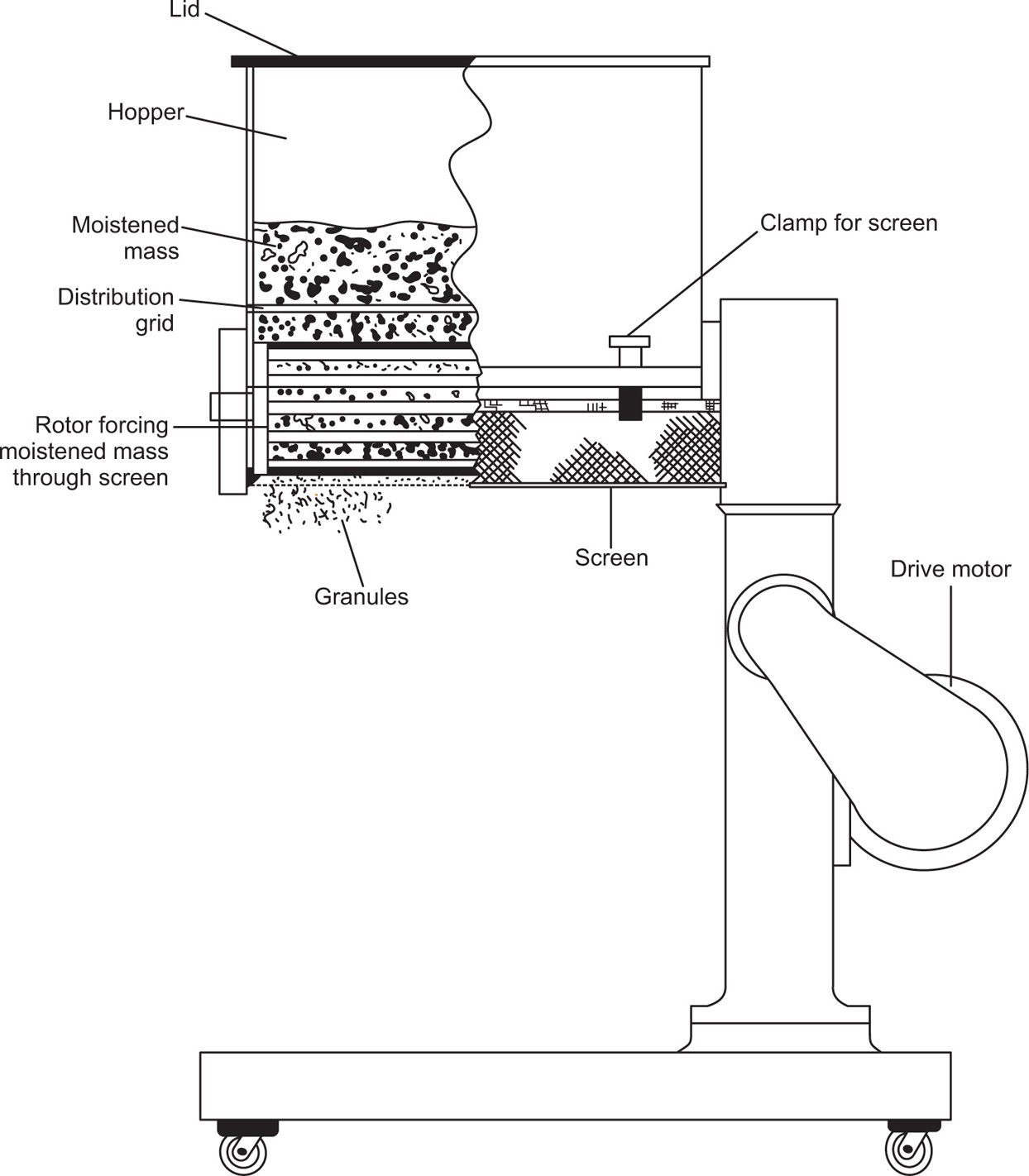

Fig. 21.4 The oscillating granulator.

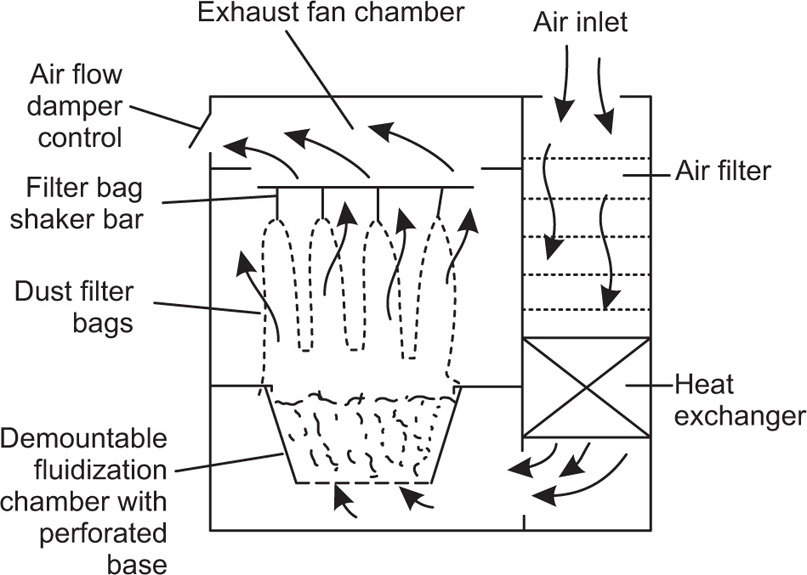

Fig. 21.5 The fluid-bed drier.

Fig. 21.6 The Calmic fluid-bed granulator. The programming panel may be seen top left. This controls application of granulating agent from the pressure vessel (centre bottom) to the material in the fluidizing chamber.

Preliminary Compression or Slugging

Dry Granulation

Flavours, Lubricants and Disintegrants

Flavours

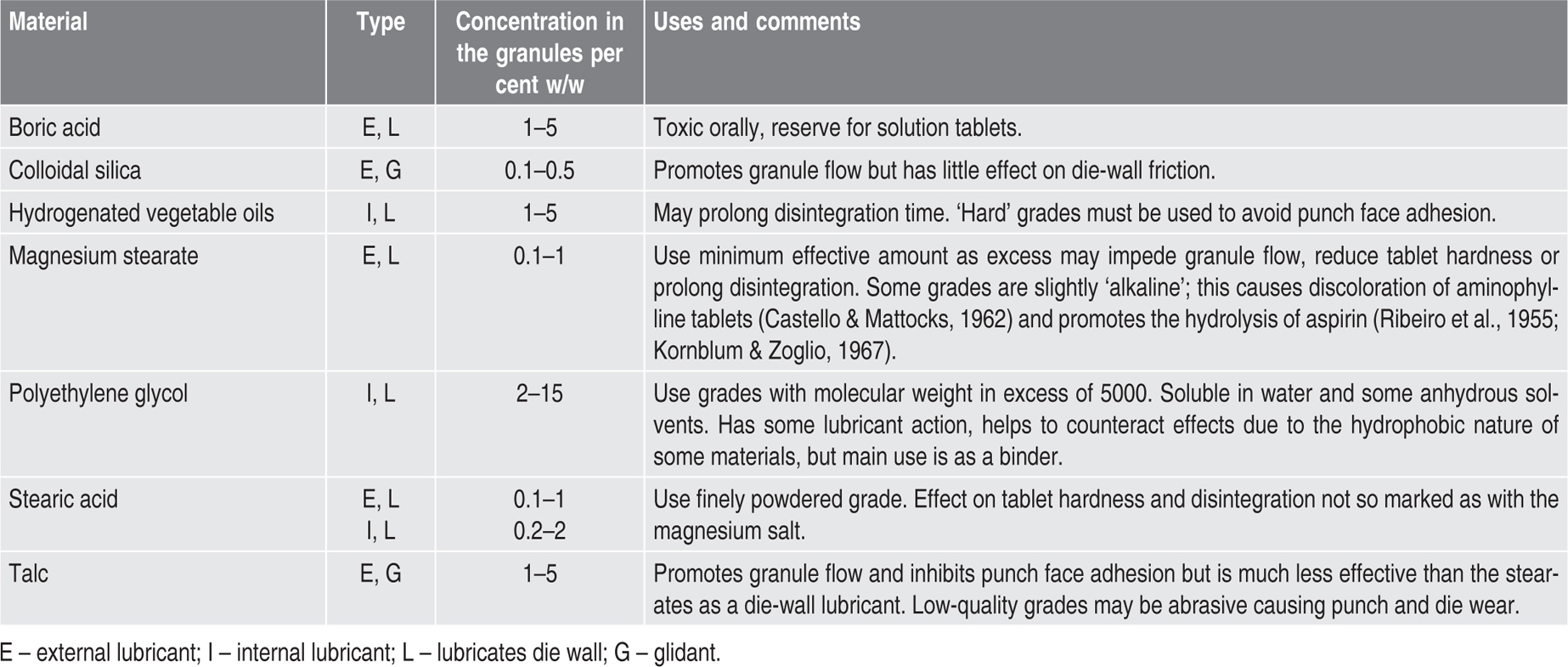

Lubricants

Disintegrants

Table 21.5 Disintegrants used in tabletting |

||

| Material | Concentration in the granules per cent w/w | Uses and comments |

| Alginic acid | 2–10 | Burster which may prove better than starch for ‘difficult’ materials (Berry & Ridout, 1950). May be incorporated prior to moistening to improve disintegration. If added to the dry granules, avoid finely powdered grades as these form a coherent gel on the tablet surface and may prolong disintegration time. |

| Magnesium aluminium silicate | 1–10 | Burster. Veegum is one variety |

| Methylcellulose | 2–10 | Burster. Use medium viscosity grade in a not too fine powder |

| Microcrystalline cellulose | 1–10 | Has some lubricant properties, higher concentrations used as dry-binding diluent |

| Sodium lauryl sulphate | 0.1–0.5 | Wetting agent which improves penetration of the tablet pore system by aqueous liquids. Will counteract the water-repellent effect of, for example, phenothiazine and the stearate lubricants. May minimize the increase in disintegration time which often occurs as tablets age |

| Starch | 2–10 | Burster. Potato and maize starch are usually considered superior to the other varieties. Part may be incorporated prior to moistening |

The Compressing Weight

Dry Granulation

| Codeine phosphate | 20.00mg |

| Stearic acid, in fine powder | 0.06mg |

| Potato starch | 0.60mg |

| Spray dried lactose | 39.34mg |

| Compressing weight | 60.00mg |

Preliminary Compression

| Per tablet (mg) | For 100,000 tablets (kg) | |

| Aspirin, in fine powder | 300 | 31.00 |

| Anhydrous citric Acid | 30 | 3.10 |

| Calcium carbonate | 100 | 10.33 |

| Saccharin sodium | 3 | 0.31 |

| Talc | 4 | 0.41 |

| Theoretical weight of ingredients | 437 | 45.15 |

| Weight of granules after slugging and rescreening | – | 44.30 |

| Weight of talc added prior to final compression | – | 0.80 |

| Total weight of granules for final compression | 45.10 |

Moist Granulation

| Medicament | 101.0kg |

| Adhesive granulating fluid | 10.6kg |

| Theoretical weight of mass | 111.6kg |

| Actual weight of moist granules | 111.1kg |

| Weight of granules after drying | 104.6kg |

| Weight of granules after screening | 104.3kg |

| Screened granules | 104.3kg |

| Disintegrant | 8.0kg |

| Lubricant | 0.5kg |

| Weight of granules for tabletting | 112.8kg |

Production of Tablets

The Single Punch Tablet Machine

Assembly

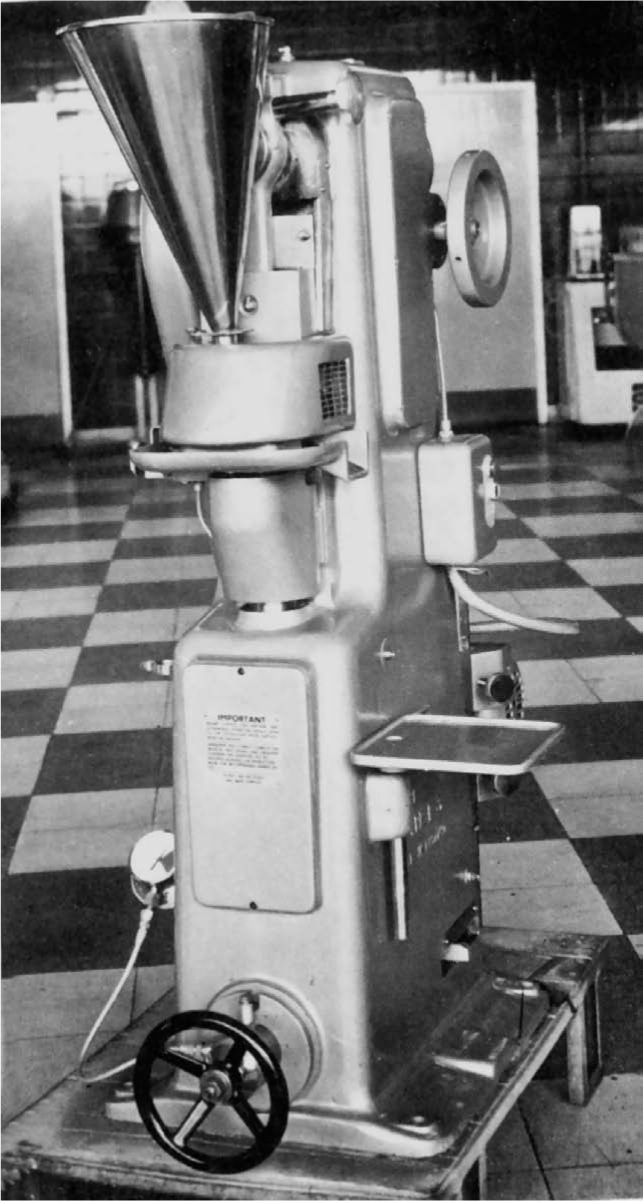

Fig. 21.7 Main operating parts of the single-punch tablet machine.

Adjustments

Operation

Fig. 21.8 Power-driven single-punch tablet machine. The top punch and the bottom punch holder are enclosed by a safety screen. The value at which overload occurs is indicated by the gauge bottom left.

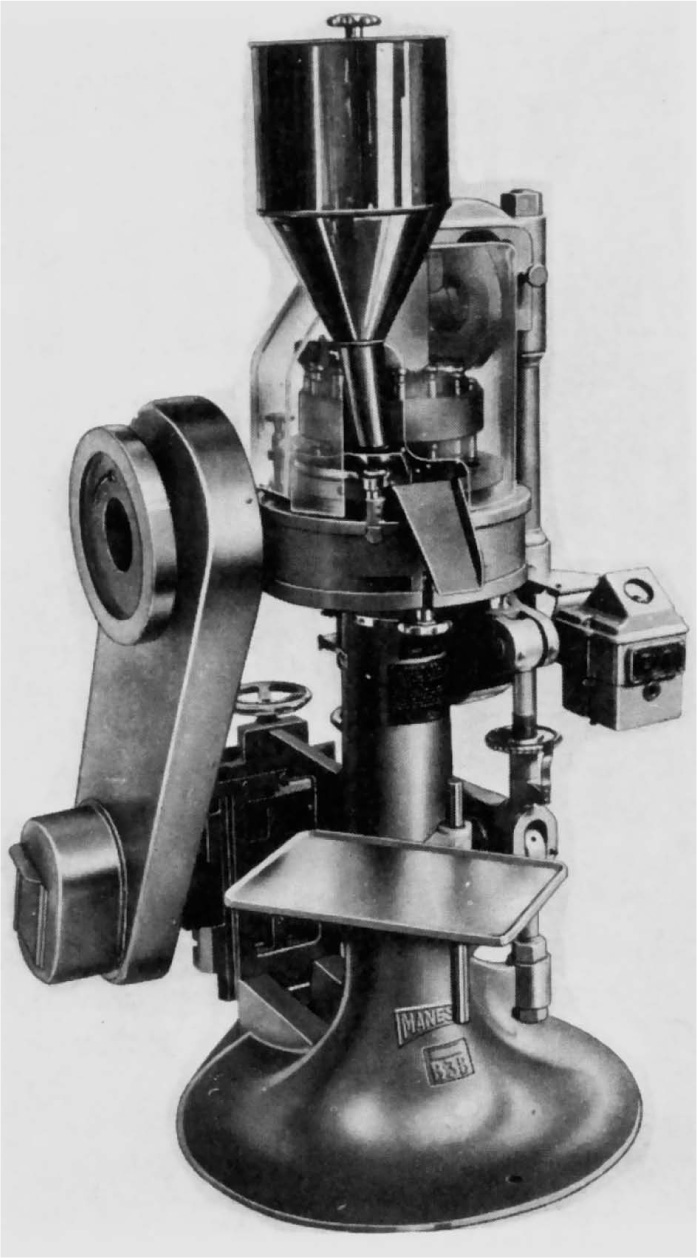

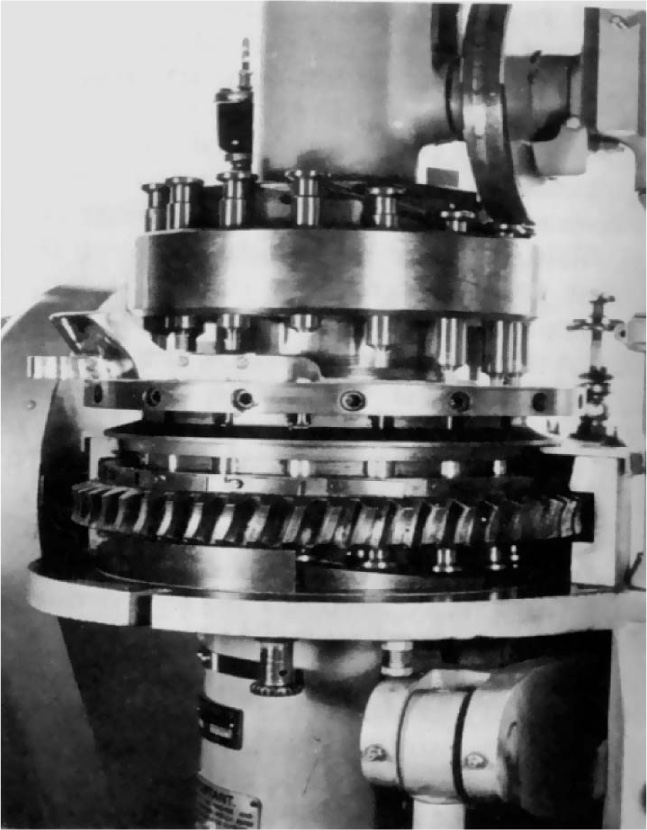

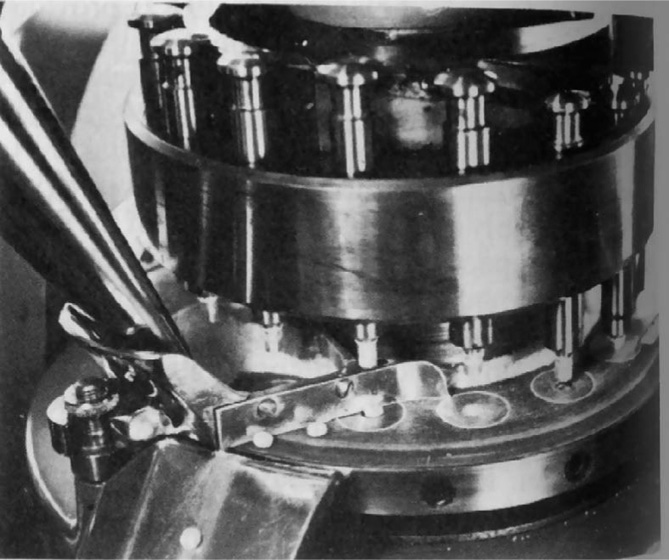

The Rotary Tablet Machine

Fig. 21.9 Medium duty 16-station rotary tablet press. The upper turret and punches are visible beneath the plastic dust screen. Manesty Machines Ltd.

Fig. 21.10 16-station rotary tablet press. The perspex screens and hopper and lower guard have been removed to show the upper and lower turrets and die table. The upper and lower cam tracks and the upper pressure roller are also visible.

Fig. 21.11 Close-up view of rotary press. The outlet of the hopper may be seen (left) feeding granules into the feed frame. Ejected tablets are being directed towards the collection chute bolted to the end of the feed frame. The upper cam track for lifting the top punch clear of the feed frame is also visible.

Fig. 21.12 69-station rotary tablet machine. Manesty Machines Ltd.

Developments in the Design of Rotary Tablet Machines

Granule Flow

Die Filling

Removal of Air

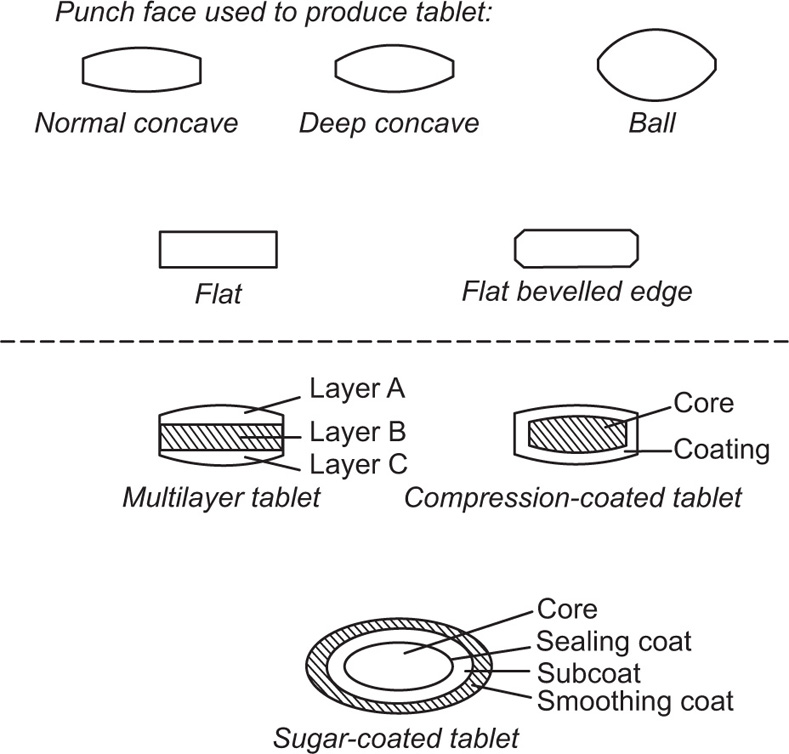

Multilayer Tablets

Punches and Dies

Fig. 21.13 Tablet profiles and structures.

Tabletting Problems

Binding in the Die

Picking and Sticking

Capping and Lamination

Excessive Weight Variation

Fissured or Pitted Surface

Soft Tablets

Protracted Disintegration

Mottled Tablets

Variation of Medicament Content

Drug Instability

Tablet Coating

Pan Coating

Fig. 21.14 Production model pan coating machine. The diameter of the bowl is about 1m. Courtesy: Vanguard Pharmaceutical Machinery

Sugar Coatings

Film Coating

Enteric Coating

Automated Pan Coating

Fluid-Bed Coating

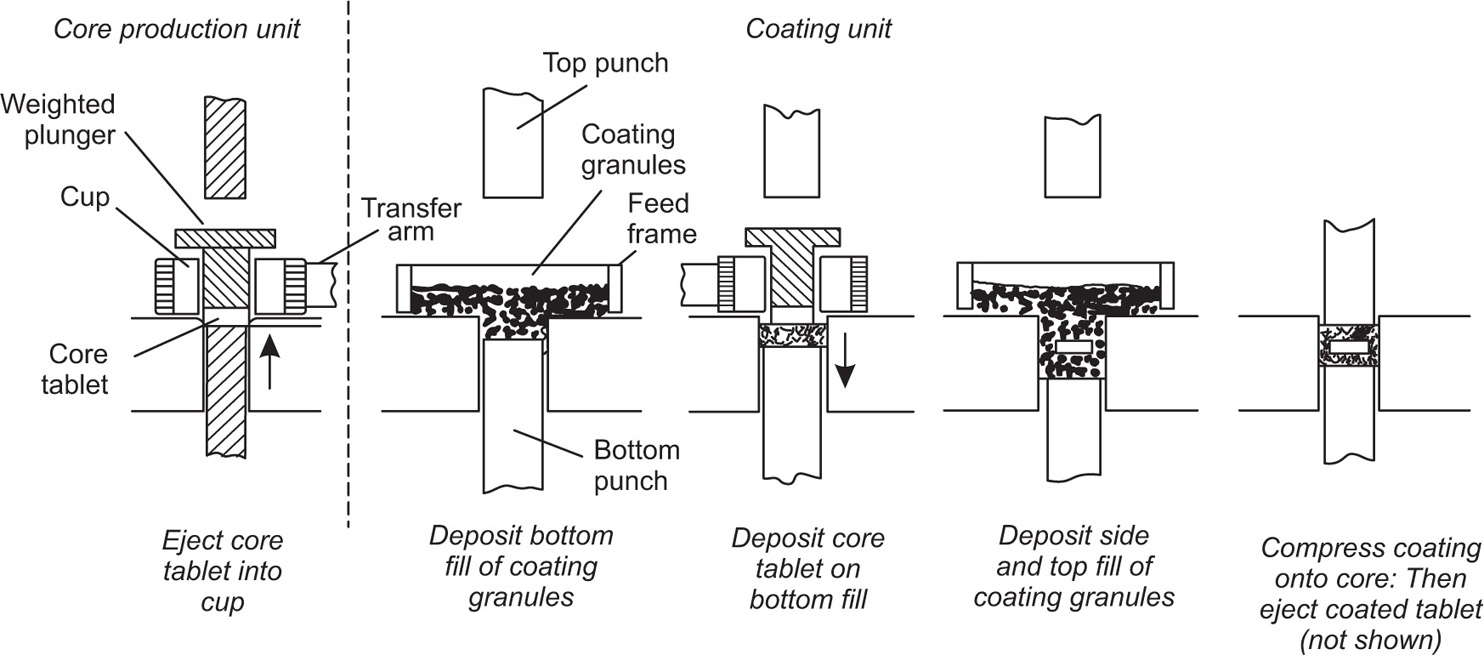

Compression Coating

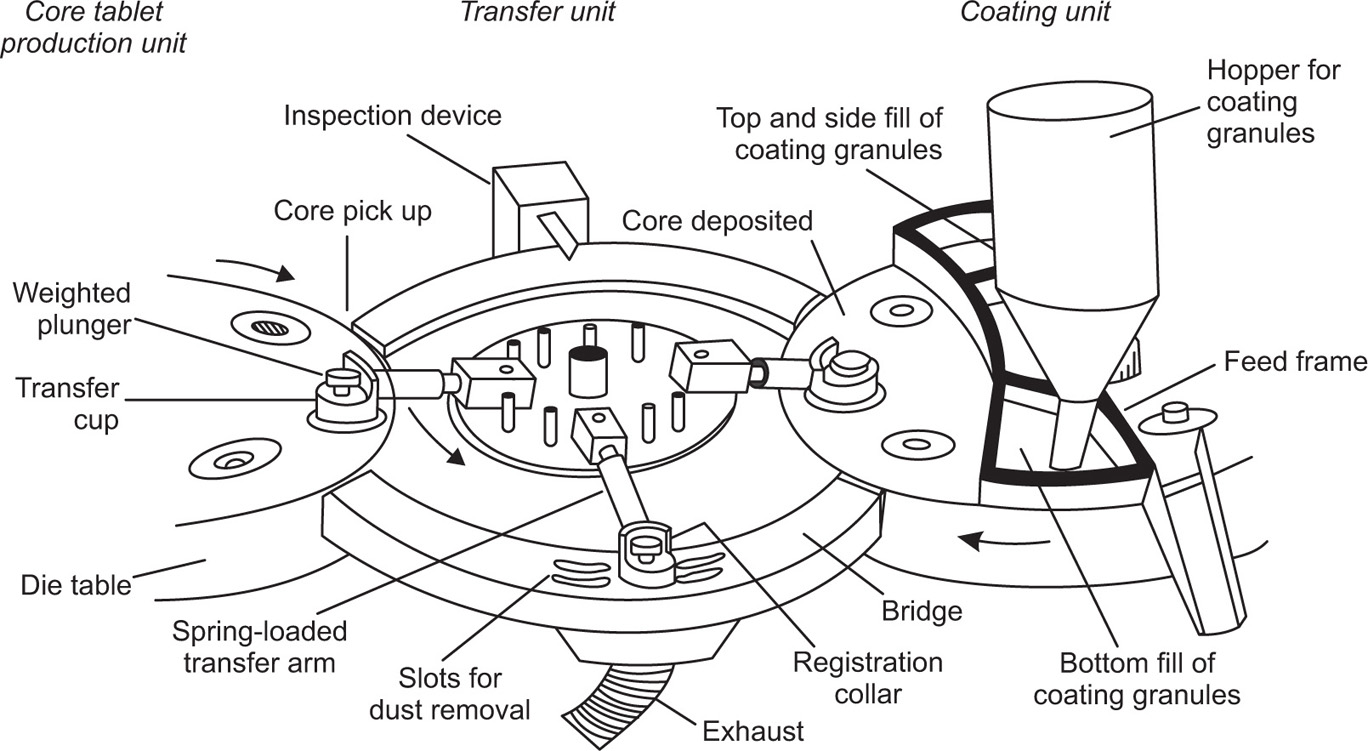

Compression Coating Machines

Fig. 21.15 The compression coating of tablets.

Fig. 21.16 Compression coating machine. The core tablet formed by the left hand unit is carried by the central transfer unit to the coating press or the right.

Fig. 21.17 Essential features of transfer mechanism of a compression coating machine (for clarity, only the die tables of the core and coating units and three transfer arms are shown).

Requirements for Core Tablets and Coating Granules

Performance

The Quality Control of Tablets

Uniformity of Diameter

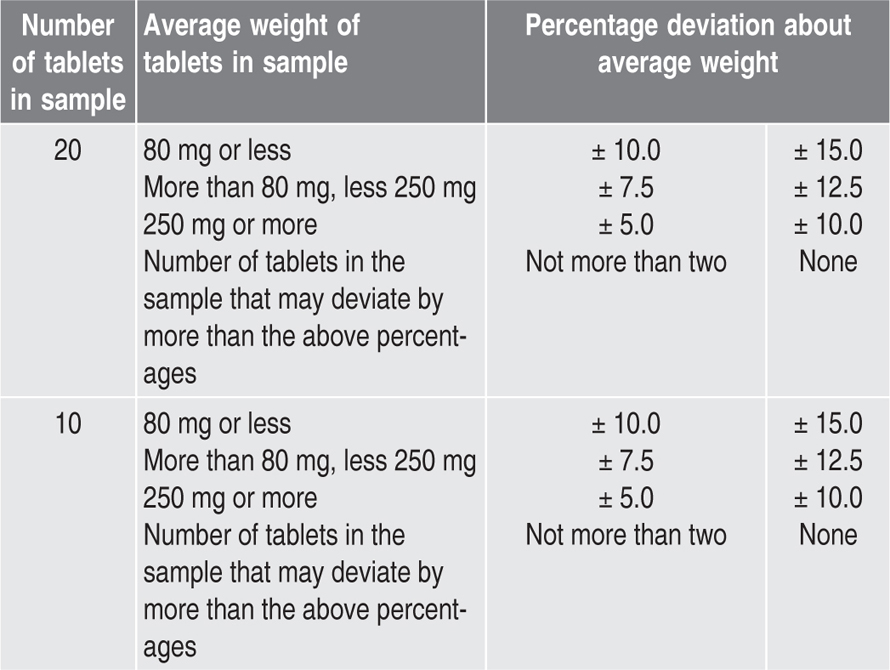

Tests for Uniformity of Weight and for Medicament Content

Test for Uniformity of Weight

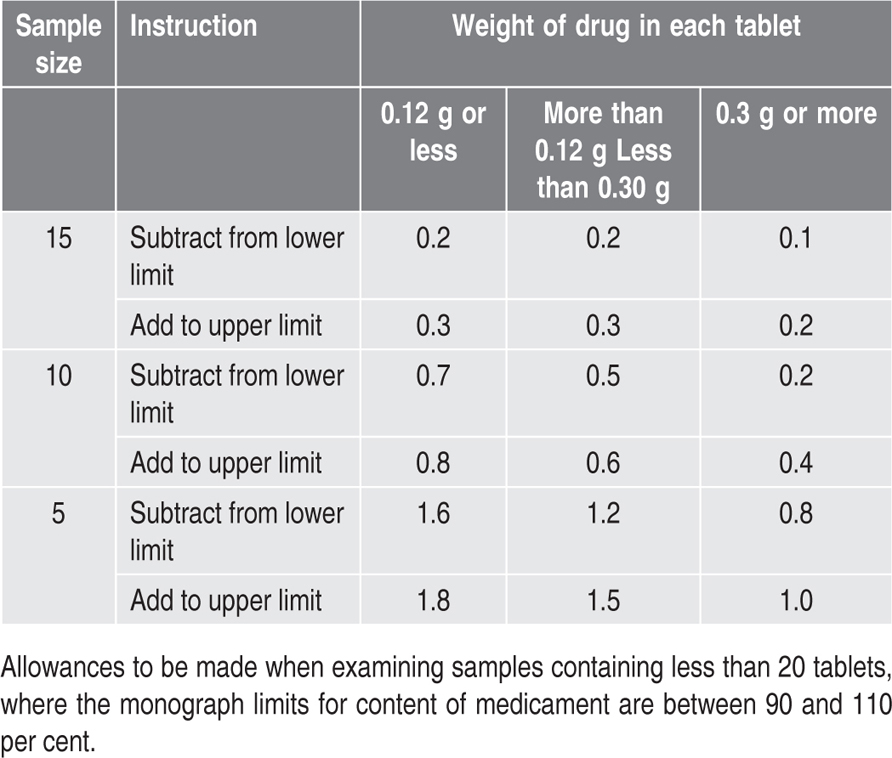

Content of Medicament

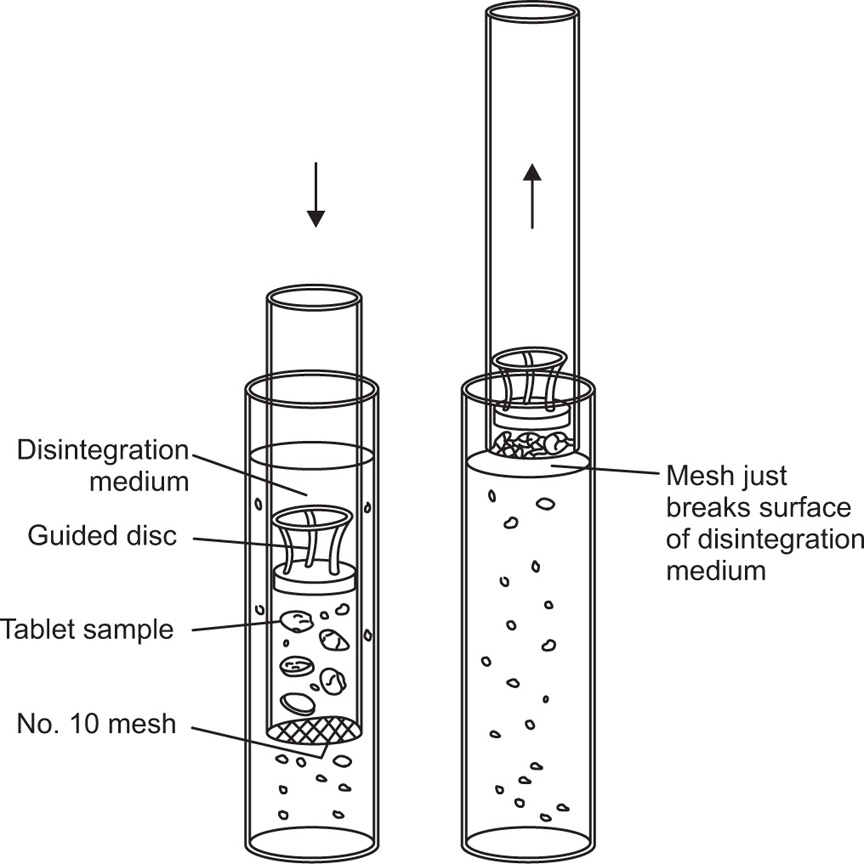

Test for Disintegration

Methods

Fig. 21.18 Essential features of apparatus for the BP 1968 disintegration test showing guide disc in use.

Requirements

Comments on the Test

Colour

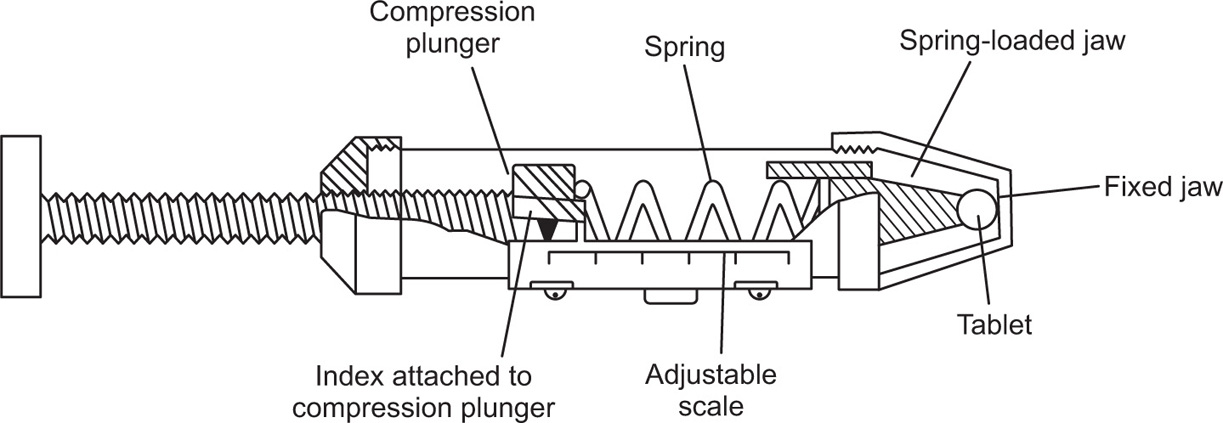

Hardness

Fig. 21.19 The Monsanto tablet hardness tester.

Theoretical Studies in Tabletting Technology

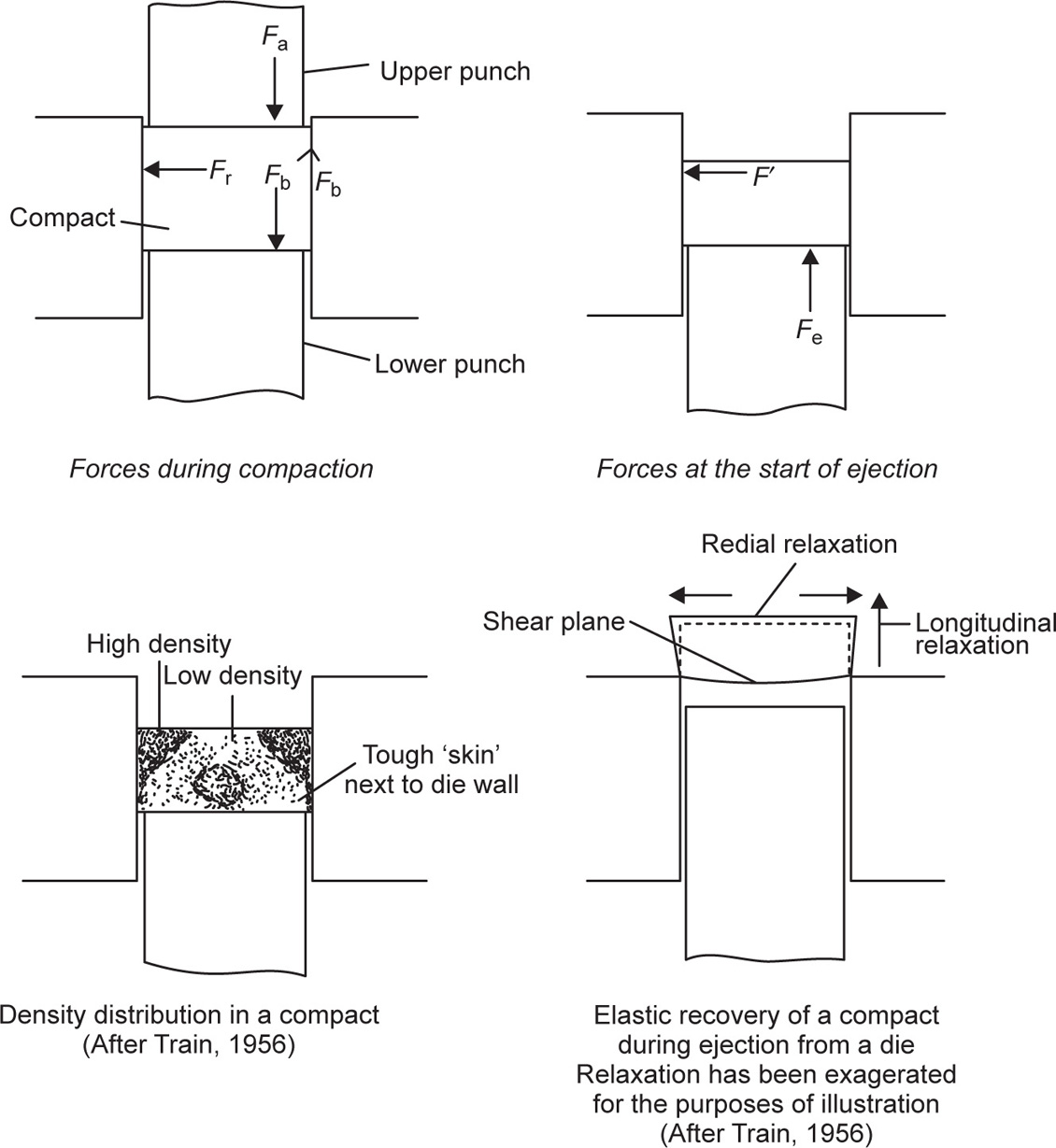

The Compaction Process

Fig. 21.20 Punch displacements and forces developed during tablet compression.

Table 21.9 Definitions of some parameters used in tabletting theory |

||

| Symbol | Definition | Derivation |

| A | Area of tablet in contact with die wall | πDL |

| Ap | Area of punch face | πD2/4 |

| D | Diameter of punch face | |

| Fa | Maximum upper punch force applied to compact | |

| Fb | Maximum force transmitted to lower punch by compact | |

| Fc | Crushing force applied across a diameter to edges of compact, just sufficient to cause rupture | |

| Fd | Force lost to the die wall | Fa – Fb |

| Fe | Maximum force applied by lower punch to initiate ejection | |

| Fr | Maximum radial force at die wall during compaction | |

| Fr | Force normal to die wall during ejection | |

| kd | Die wall coefficient of friction during compaction | |

| ke | Die wall coefficient of friction during | |

| L | Observed length of compact | |

| L0 | Length compact would assume if compressed to zero porosity | W/Apρ0 |

| Pa | Maximum upper punch pressure | Fa/Ap |

| Pb | Maximum lower punch pressure | Fb/Ap |

| Pm | Mean compaction pressure | (Pa + Pb)/2 |

| Pr | Maximum radial pressure during compaction | Fr/A |

|

Radial pressure during ejection of compact |  |

| R | Punch force ratio | Fb/Aa |

| T | Transmission ratio | Fb/A |

| V | Observed volume of tablet | Ap/La |

| V0 | Volume compact would assume if compressed to zero porosity | Pr/Pa |

| Vr | Relative volume of compact | Ap/La |

| W | Weight of tablet | W/ρ0 |

| ε | Porosity ratio of void to total volume | V/V0 |

| ρ | Observed density of compact | (V−V0)/V, 1 − ρr |

| ρ0 | True density of material used in compaction study | W/V |

| ρr | Relative density of tablet | ρ/ρ0, 1/Vr |

It is assumed that the punches are flat faced and circular in section. |

||

Fig. 21.21 Physical conditions during tabletting.

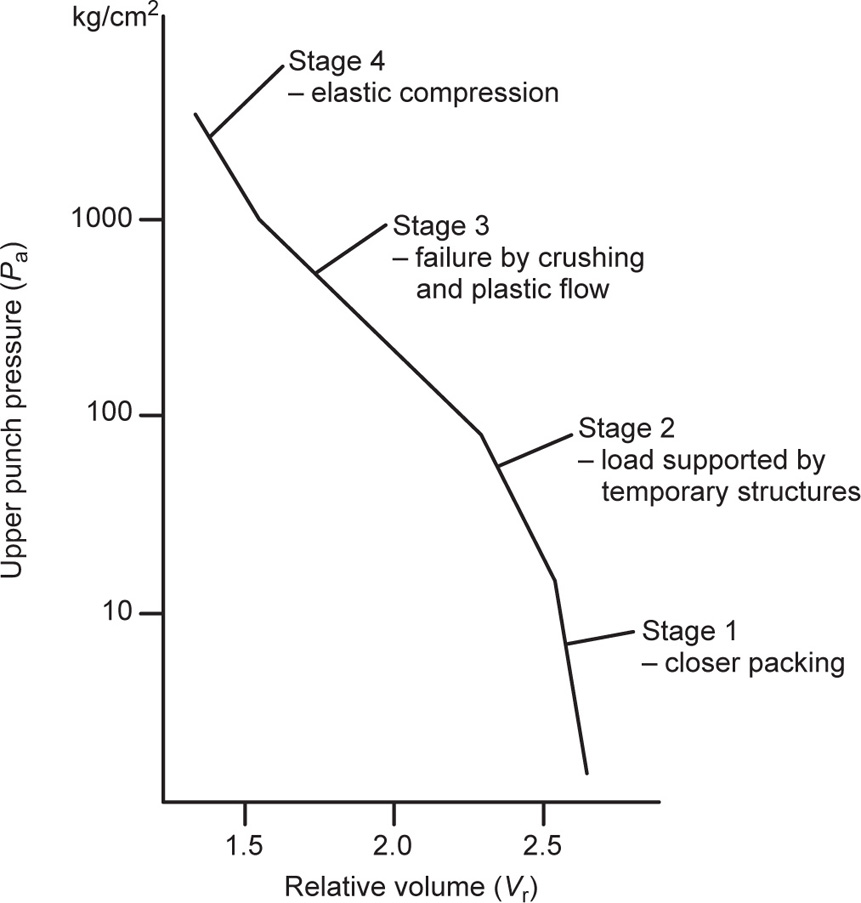

Fig. 21.22 Stages in the compaction of magnesium carbonate.

Tablet Hardness

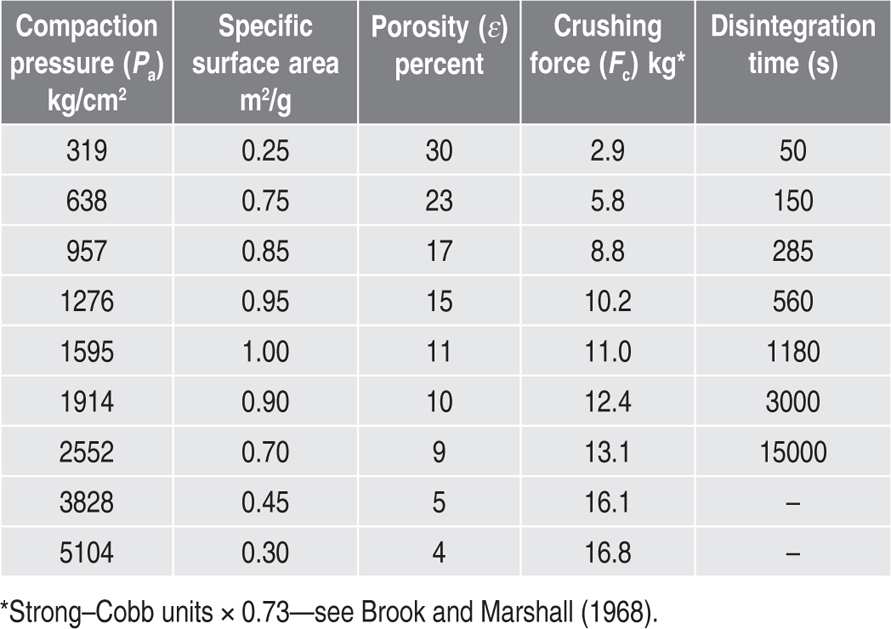

Effect of Compaction Pressure

Effect of Materials Used and Tablet Dimensions

(21.1)

(21.1)

Capping and Lamination

Granule Bonding and Relaxation Stresses

Residual Die-Wall Pressure

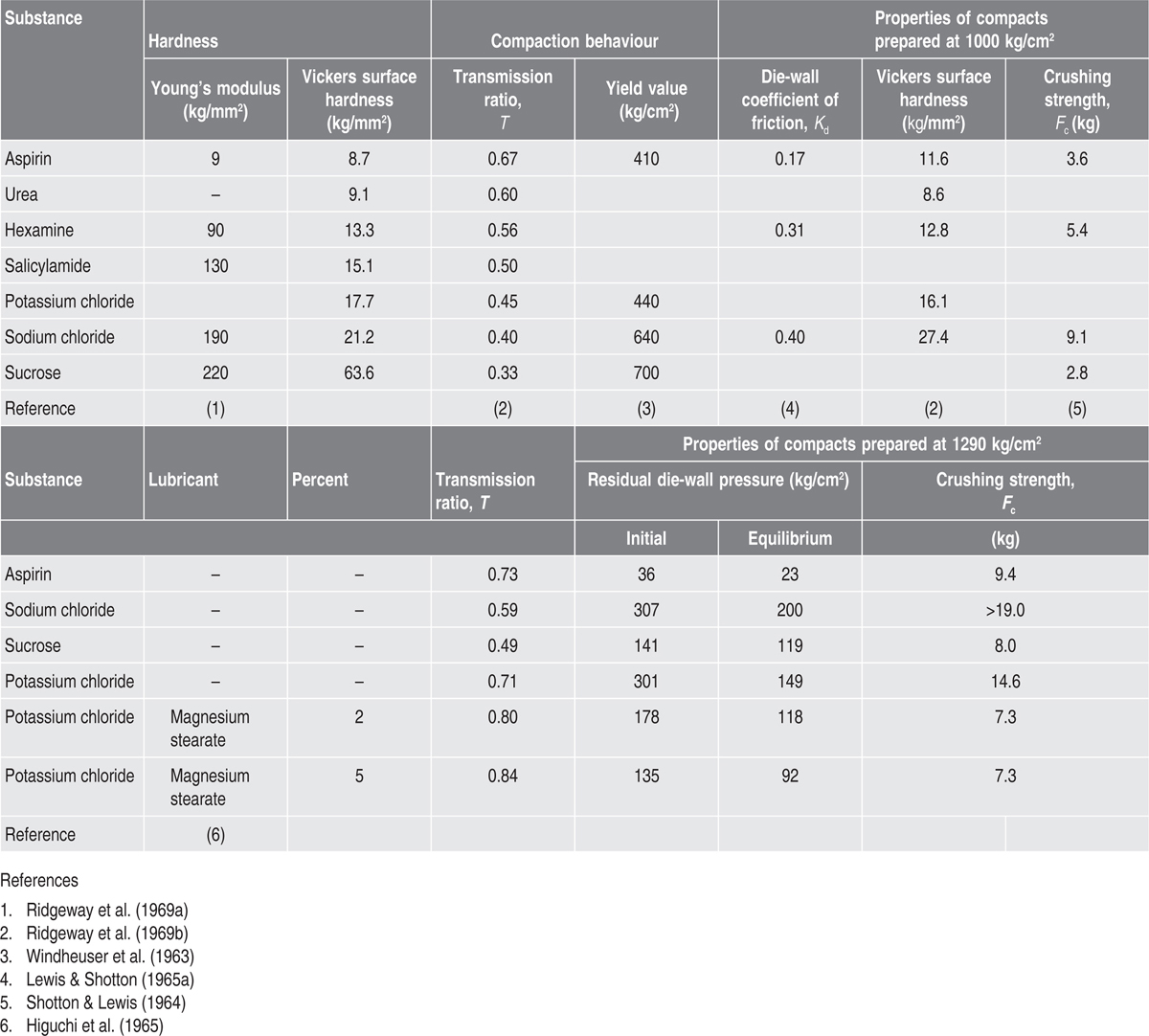

Hardness of Materials and Tablet Properties

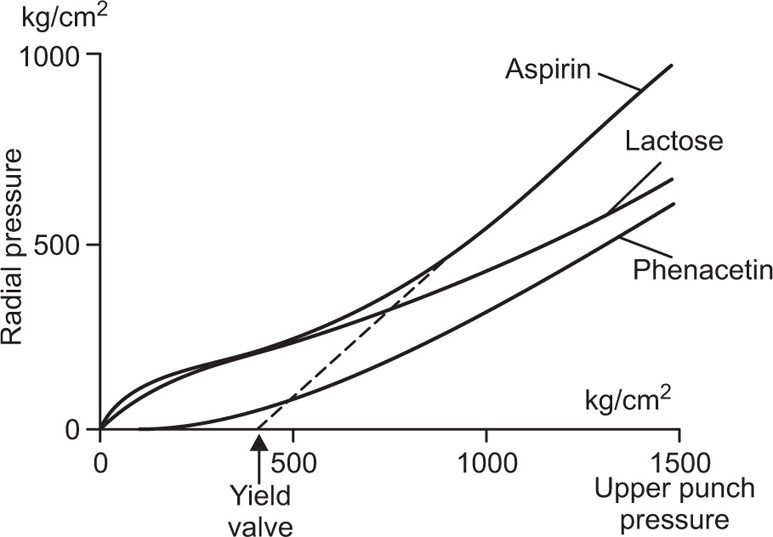

Fig. 21.23 Radial pressure as a function of upper punch pressure. after Windhesuer et al., 1963

Lubrication

Glidants

Die-wall Lubricants

(21.2)

(21.2)

Table 21.13 Effect of lubricants on the disintegration time of sodium bicarbonate tablets compacted at approximately 1300kg/cm2 |

||

| Lubricant concentration per cent | Disintegration time (s) Stearic acid | Magnesium stearate |

| 0 | 200 | 200 |

| 0.25 | 370 | 1500 |

| 0.50 | 520 | 2000 |

| 0.75 | 680 | 2200 |

| 1.00 | 900 | 2300 |

| 2.00 | 1400 | 2900 |

| 4.00 | 2500 | 3800 |

(21.3)

(21.3)

, the radial force operating as ejection takes place, constitutes the normal load. As Fr = Pr A and

, the radial force operating as ejection takes place, constitutes the normal load. As Fr = Pr A and  , by analogy with Eq. 21.3:

, by analogy with Eq. 21.3: (21.4)

(21.4)

(21.5)

(21.5)

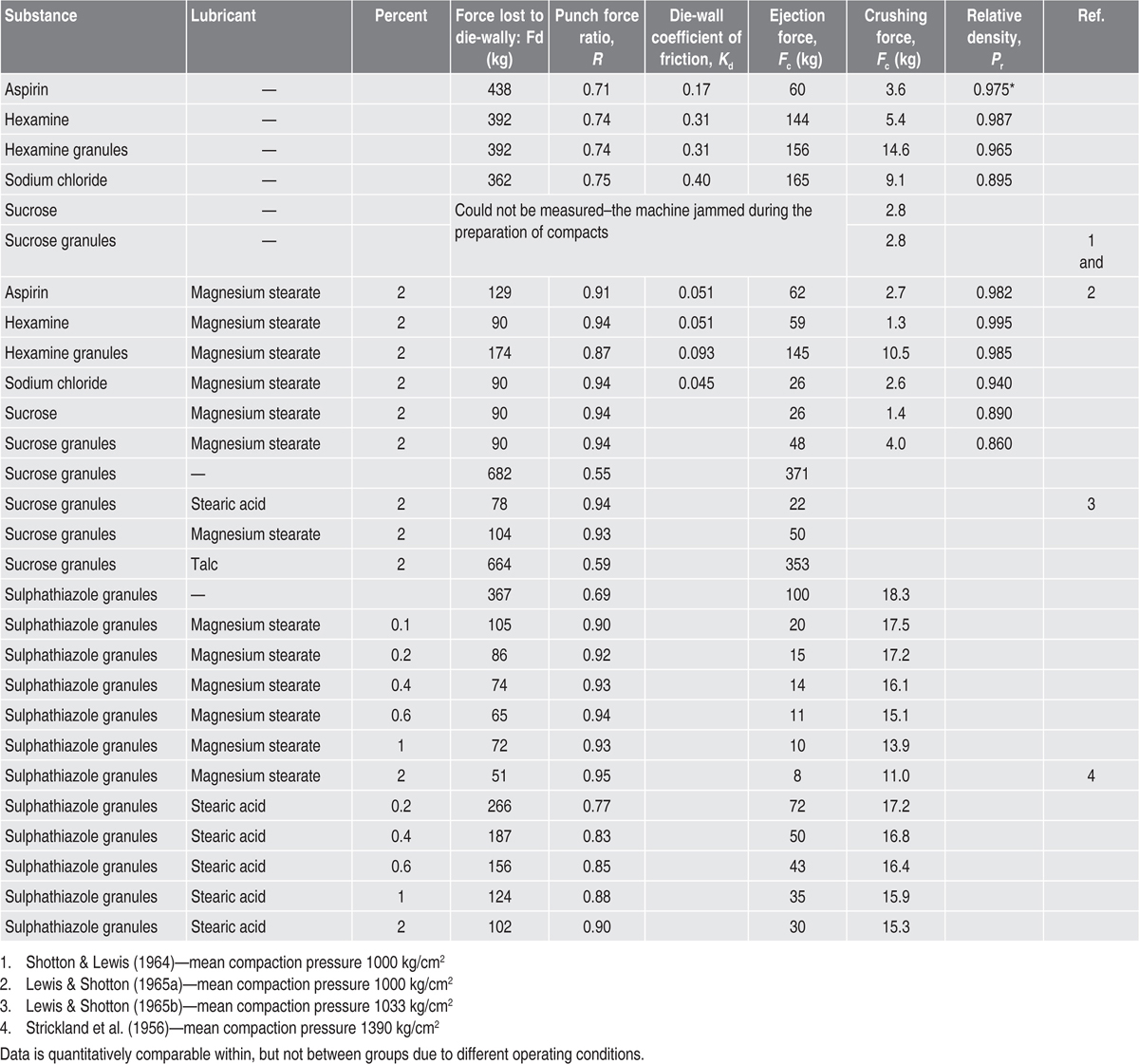

are proportional to a generalized compaction pressure (P) the appropriate substitution in Eqs. (21.4) and (21.5) yields expressions with a common factor (PA), which implies that Fe and Fd are linearly related. This has been confirmed by, for instance, Train (1956), Lewis and Shotton (1965a) and by other workers. Clearly, this is a simplification of a very complex process and could not be expected to apply directly to all materials and compaction conditions. Train’s data for the ejection of magnesium carbonate compacts was best represented by a power law, but Lewis and Shotton used linear expressions:

are proportional to a generalized compaction pressure (P) the appropriate substitution in Eqs. (21.4) and (21.5) yields expressions with a common factor (PA), which implies that Fe and Fd are linearly related. This has been confirmed by, for instance, Train (1956), Lewis and Shotton (1965a) and by other workers. Clearly, this is a simplification of a very complex process and could not be expected to apply directly to all materials and compaction conditions. Train’s data for the ejection of magnesium carbonate compacts was best represented by a power law, but Lewis and Shotton used linear expressions: (21.6)

(21.6)

(21.7)

(21.7)

are determined by the transmission ratio (T) and this would not be identical for all lubricated substances which explains why these produced different values of Fd and Fe at a given mean compaction pressure.

are determined by the transmission ratio (T) and this would not be identical for all lubricated substances which explains why these produced different values of Fd and Fe at a given mean compaction pressure.

(21.8)

(21.8)

is proportional to Pa:

is proportional to Pa: (21.9)

(21.9)

Disintegration

Theory

(21.10)

(21.10)

(21.11)

(21.11)

(21.12)

(21.12)

(21.13)

(21.13)

(21.14)

(21.14)

Effect of Granule Properties

Effects of Die-Wall Lubricants

Mode of Disintegrant Action

Capsules

Soft Capsules

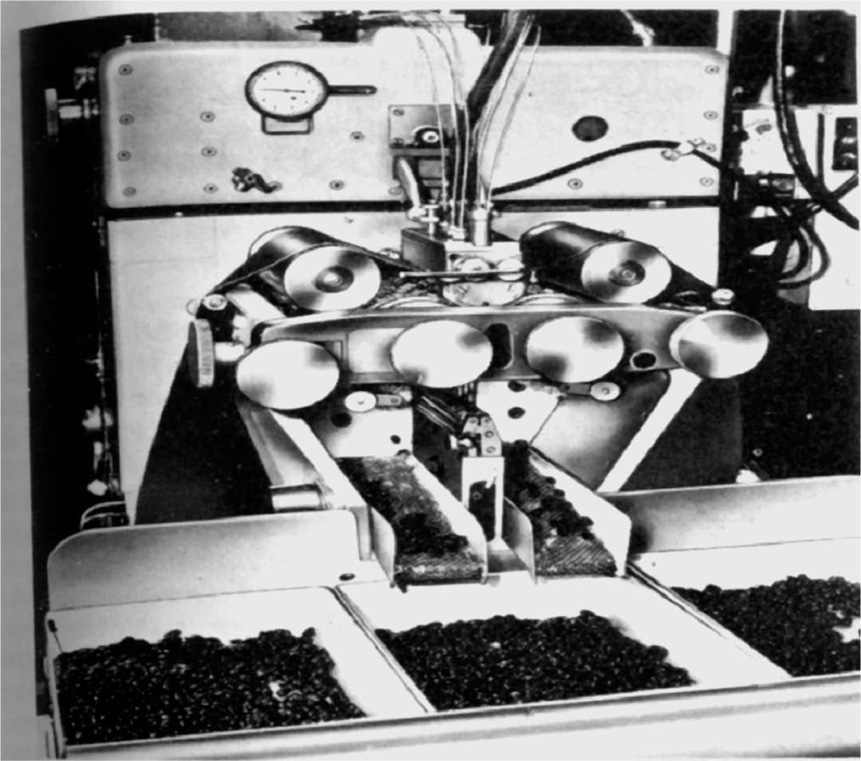

Fig. 21.24 The rotary die soft capsule filling machine. R.P. Scherer Ltd.

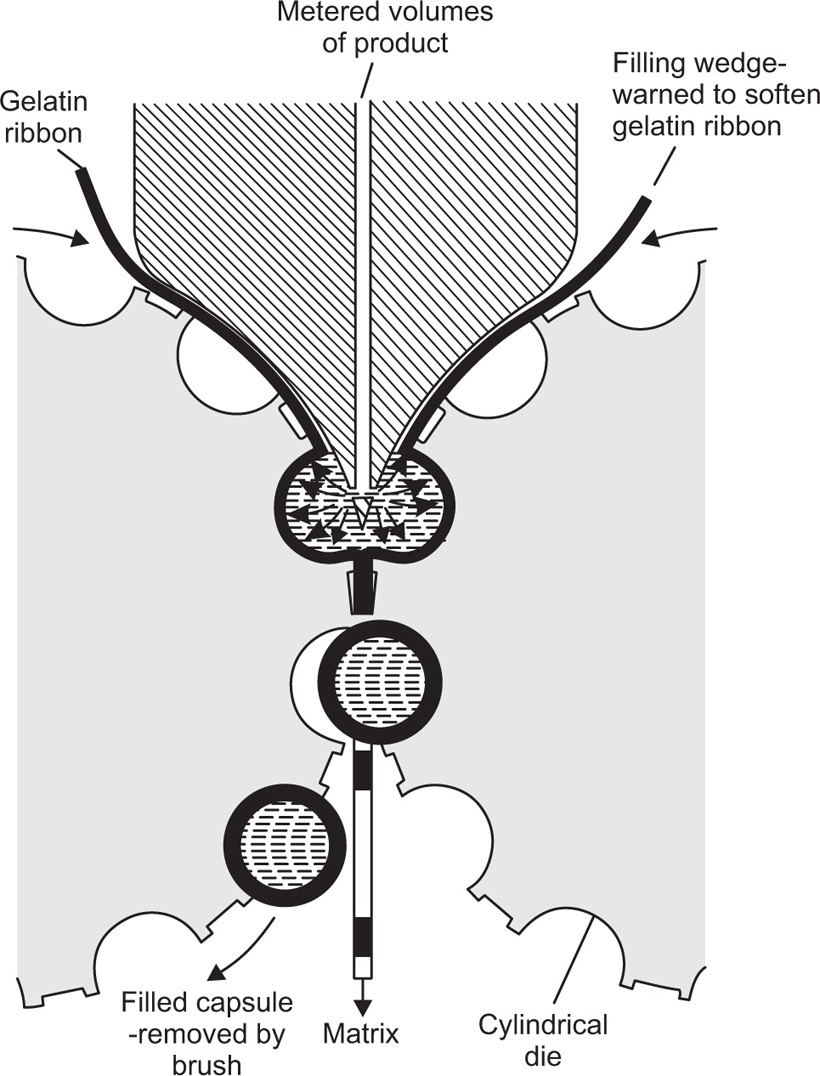

Fig. 21.25 Method of filling and sealing soft gelatin capsules in a rotary die machine (diagrammatic).

Hard Capsules

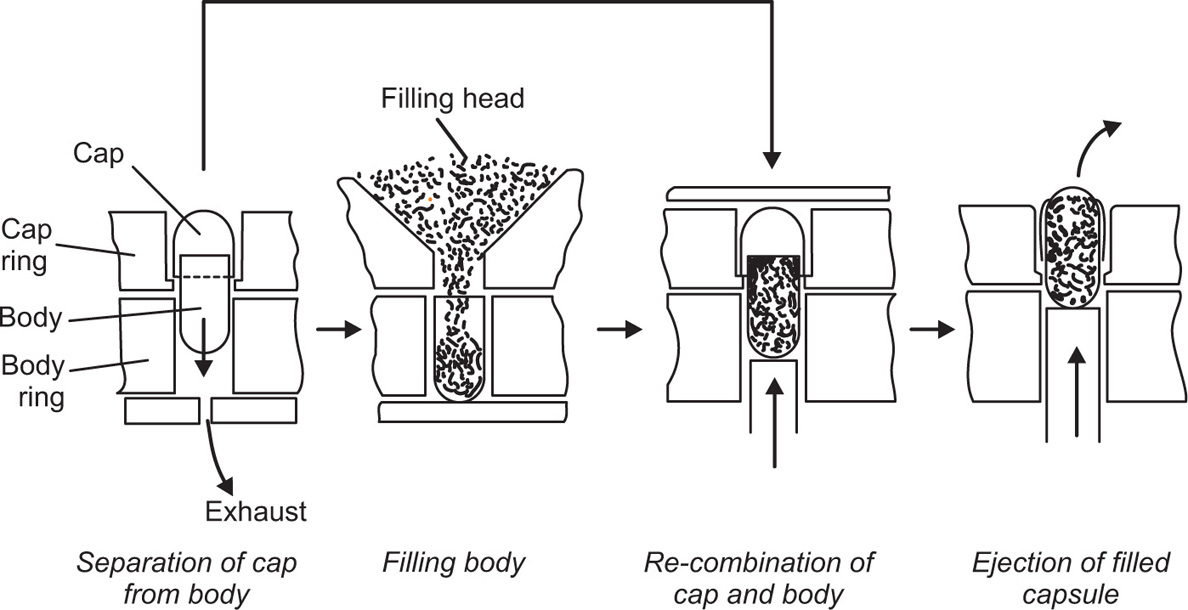

Fig. 21.26 Stages in the filling of hard capsules.

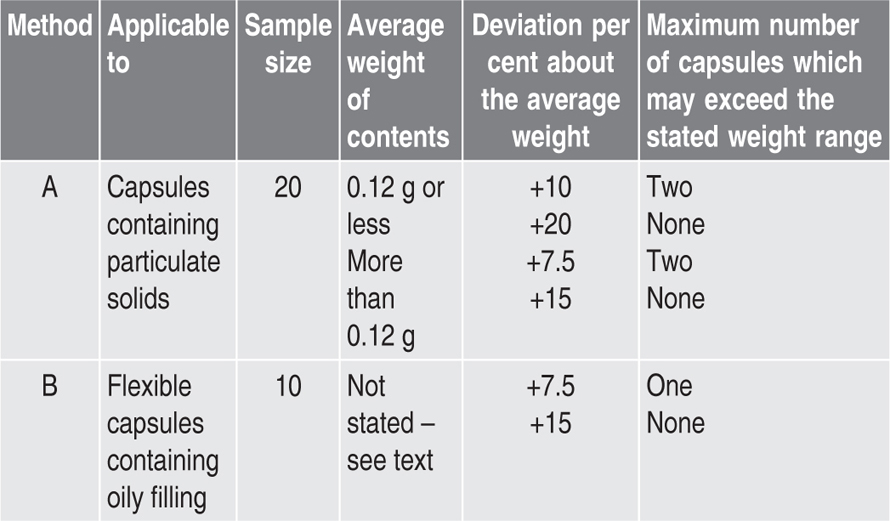

Quality Control of Capsules

Disintegration

Uniformity of Filling Weight