Breathing Circuits

CLASSIFICATIONS OF BREATHING CIRCUITS

Chemical Absorption of Carbon Dioxide

Use of Valves to Separate Exhaled Gases from Inhaled Gases

Use of Open-Drop Ether or a T-Piece Without a Reservoir to Release Exhaled Carbon Dioxide into the Atmosphere

The Anesthesia Machine

The anesthesia machine serves to create a desired mixture of anesthetic gases, vapors, oxygen, and air (as well as other gases such as helium and carbon dioxide, albeit less frequently). The patient is the recipient of these prepared gas mixtures of known composition, and the breathing circuit is the interface between the anesthesia machine and the patient. This circuit delivers the gas mixture from the machine to the patient as it removes carbon dioxide, excludes operating room (OR) air, and conditions the gas mixture by adjusting its temperature and humidity. It converts continuous gas flow from the anesthesia machine to the intermittent flow of breathing, facilitates controlled or assisted respiration, and provides other functions such as gas sampling and pressure and spirometric measurements.

The desirable characteristics of a breathing circuit include 1) low resistance to gas flow, 2) minimal rebreathing of the preceding alveolar expirate, 3) removal of carbon dioxide at the rate at which it is produced, 4) rapid changes in delivered gas composition when required, 5) warmed humidification of the inspirate, and 6) safe disposal of waste gases. The components of a breathing circuit include the breathing tubing; respiratory valves; reservoir bags; carbon dioxide absorption canisters; a fresh gas inflow site; a pop-off valve leading to a scavenger for excess gas; a Y-piece with a mask or tube mount; and a face mask, laryngeal mask, or tracheal tube. Other devices that may be included are filters; humidifiers; valves for positive end-expiratory pressure (PEEP); and detecting mechanisms for airway pressure, spirometry, and gas analysis. Although these circuit components can be assembled in many ways, contemporary systems are usually configured by the manufacturer and permit little intervention by the user in regard to their configuration. Understanding the advantages and limitations of the different configurations allows the user to select the most appropriate type for varying clinical settings.

History of Device Development

Breathing circuits have been an important concern from the start. Because of a delay in the production of his inhaler, Morton was late to his first public exhibition of the “Somniferon” (ether) in 1846. The earliest circuits were mechanically simple; differences among them were related to the characteristics of the primary anesthetic agent. Because nitrous oxide and ether anesthetic mixtures were weak (less potent) or slow to produce anesthesia, it was necessary to exclude air and helpful to include oxygen enrichment. The rapid onset of action and potency of chloroform, on the other hand, demanded precise control. It became apparent that the unique features of each agent were important. The ability to assist respiration was advantageous, as was conservation of costly agents and avoidance of large leaks of flammable ones.

In the twentieth century, a large number of relatively small but more highly engineered improvements were made as other demands on the breathing circuit were recognized. In 1915, Dennis Jackson described the first carbon dioxide absorber to save on the cost of nitrous oxide for animal studies.1 Ralph Waters brought the idea into the OR, designing a to-and-fro absorption canister that used soda lime.2,3 Bryan Sword introduced the first circle breathing circuit in 1930.4 Thus low-flow absorption systems were already in use when cyclopropane made them essential. A return to high flows in the United States was brought about by the poor performance of vaporizers for halothane in the 1950s, with the demonstration that such flows could eliminate carbon dioxide without the use of soda lime.5,6

Stimulated by Magill’s use of a number of pieces of apparatus put together in differing configurations for differing purposes, Mapleson described a variety of Magill circuits.7 The original Ayre’s T-piece was modified by numerous practitioners; the Jackson-Rees circuit represents one such example.8 A variety of proprietary nonrebreathing valves were introduced, and the circuits named for them included the Stephen-Slater,9 the Fink,6 the Ruben,10 and the Frumin.11

Partial rebreathing and functionally nonrebreathing circuits—such as the Bain,12 Humphrey ADE,13 and Lack14 systems—found various proponents. Ingenious switching valves permitted transfiguration from one circuit to another,13 which led to difficulty in remembering which circuit was optimal for what purpose.

Today, in addition to factors of convenience and economy, circuits are used to control heat and humidity; to measure patient variables such as tidal volume, respiratory frequency, airway pressure, and inspired and expired gas concentrations; and to control contamination of the OR environment by the agents themselves. The 150-year history of the development of the breathing circuit offers the practitioner a number of choices. All commonly used circuits accomplish their goals more or less equivalently, but the simple act of increasing fresh gas flow, for example, may markedly increase the work of breathing.15 Therefore it is vital that the anesthesiologist understand the functional characteristics of each circuit.

Classifications of Breathing Circuits

A widely used nomenclature was developed that classified circuits as open, semiopen, semiclosed, or closed, according to whether a reservoir is used and whether rebreathing occurs. An open system has no reservoir and no rebreathing; a semiopen system has a reservoir but no rebreathing; a semiclosed system has a reservoir and partial rebreathing; and a closed system has a reservoir and complete rebreathing. Variations on this classification included the type of carbon dioxide absorber and unidirectional valves used.

Because of confusion with this traditional nomenclature, Hamilton recommended its abandonment in favor of both a description of the hardware (e.g., circle filter system, coaxial circuit, T-piece) and the gas flow rates being used.16 Identifying the circuits by eponym—such as Adelaid, Bain, Hafnia, Humphrey, Jackson-Rees, Lack, Magill, and Waters—did not help in understanding the function or application of the circuit. Almost all anesthesia machines are equipped with some form of a circle breathing circuit with the ability for carbon dioxide absorption during low-flow anesthesia and elimination through the pop-off valve during high-flow anesthesia. Because an understanding of how circuits work is essential, breathing circuits in this chapter are organized by method of carbon dioxide elimination. Methods for removal of carbon dioxide are discussed.

Chemical Absorption of Carbon Dioxide

Semiclosed and closed systems (i.e., circle and to-and-fro) rely on chemical absorption of carbon dioxide. Exhaled carbon dioxide is absorbed, and all other exhaled gases are rebreathed. The quantities of fresh oxygen and anesthetics equal those lost as a result of uptake, metabolism, and circuit leaks.3,17,18

Dilution with Fresh Gas

Because of the intermittent nature of carbon dioxide excretion (during exhalation only) and the continuous inflow of fresh gas, the choice of inflow rate—as well as the locations of the inflow site, reservoir bag, and pop-off valves—contributes to the efficiency of carbon dioxide removal. When fresh gas flows are 1 to 1.5 times the minute volume (approximately 10 L/min in an adult), dilution alone is sufficient to remove carbon dioxide.17,19-23 Such systems then behave the same as a nonrebreathing system.

Use of Valves to Separate Exhaled Gases from Inhaled Gases

Systems that use nonrebreathing valves are examples of this method of carbon dioxide removal.6,9,11,24,25 A circuit that by virtue of high flows behaves as if it were nonrebreathing is not considered a nonrebreathing circuit in this analysis.

Use of Open-Drop Ether or a T-Piece Without a Reservoir to Release Exhaled Carbon Dioxide into the Atmosphere

Although similar to the second method above, systems that used open-drop ether or a T-piece without a reservoir were not truly breathing circuits. The T-pieces with an expiratory reservoir rely on dilution of carbon dioxide by both fresh gas and room air for its removal; these have been included in semiclosed circuits below.26

Components of A Breathing Circuit

The circuits described above have many features in common; they connect to the patient’s airway through a face mask, laryngeal mask, or tracheal tube adapted to the breathing circuit through a Y-piece or elbow. The system may include valves to permit directional gas flow, and a reservoir bag is almost always present, which can be used to manually force gas into the lungs. Fresh gas must be supplied to the circuit, and excessive gas must be allowed to escape. In some, carbon dioxide is absorbed in a chemical filter. A variety of ancillary devices may also be present, such as humidifiers, spirometers, pressure gauges, filters, gas analyzers, PEEP devices, waste gas scavengers, and mixing and circulating devices.

Connection of the Patient to the Breathing Circuit

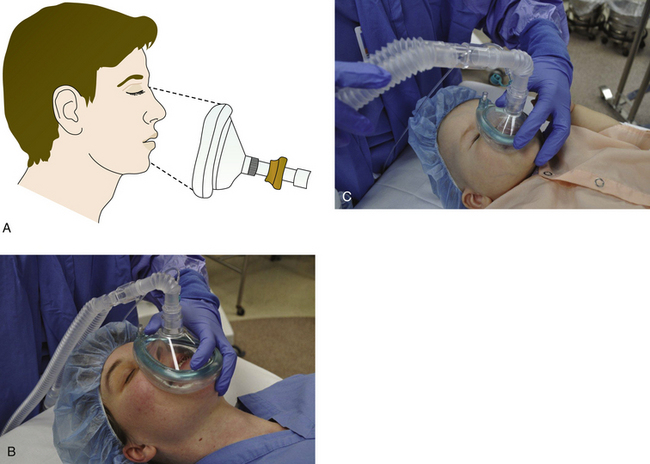

Either an anesthesia mask, supraglottic device, or a tracheal tube connects the circuit to the patient. Masks are made from rubber or clear plastic to make secretions or vomitus visible (Fig. 4-1). Most have an inflatable or inflated cuff, a pneumatic cushion that seals to the face. Masks are available in a variety of sizes and styles to accommodate the wide variety of facial contours. For example, a prominent nasal bridge may prevent a tight fit if the mask’s cuff is flat at that point. A prominent chin (mentum) with sunken alveolar ridge causes a leak at the corner of the mouth, and the volume of the mask contributes to apparatus dead space. The mask should fit between the interpupillary line over the nose and in the groove between the mental process and the alveolar ridge (Fig. 4-2). The average length of this area is 85 to 90 mm in adults. The newest disposable plastic masks are available in a wide range of sizes, intended to fit the faces of small children and large adults equally well. Choosing from a selection of mask sizes and styles is more rational than a “one size fits all” approach because a poorly fitting mask can result in trauma to the patient. This is especially true when the mask must be positioned above the eyebrows because it can cause pressure on, and possibly damage to, the optic and supraorbital nerves. Masks often have a set of prongs for attachment to a rubber mask holder or head strap; however, if pulled too tight, this mask holder may obstruct the airway. Masks connect to the Y-piece or elbow via a 22-mm (⅞-inch) female connection.

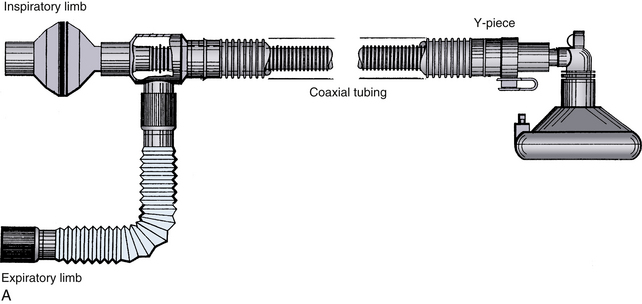

Breathing Tubing

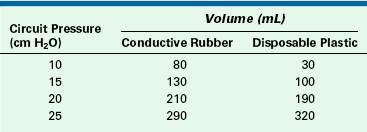

The tubing used in breathing circuits typically is approximately 1 meter in length, has a large bore (22 mm) to minimize resistance to gas flow, and has corrugations or spiral reinforcement to permit flexibility without kinking. The internal volume is 400 to 500 mL/m of length. Although these tubes were formerly made of conductive rubber, disposable plastic tubing has almost completely replaced rubber. Electrical conductivity is no longer necessary when breathing tubing is used with nonflammable agents. The advantage of plastic is that it is lightweight; however, it is not biodegradable and thus is disposable by design although not by use. Plastic tubing for a breathing circuit is supplied sterile despite the lack of convincing epidemiologic data to support the necessity of sterile tubing.27,28 On occasion, it is necessary to pass a breathing circuit on to the sterile surgical field (e.g., during an ex utero intrapartum treatment procedure). By convention, the ends of the tubing are 22 mm in internal diameter (ID) and are identical in design. Tubing should be inspected before use because manufacturing errors can result in obstruction of the lumen.29,30 Compliance of the tubing varies from nearly 0 to more than 5 mL/m/mm Hg of applied pressure, and plastic tubing has lower values than rubber (Table 4-1). Apparent distensibility is even greater because compression of gas under pressure, to the order of 3% of the volume, occurs at typical inflation pressures. Inflation of a patient’s lungs to 20 cm H2O peak inspiratory pressure compresses 30 to 150 mL of gas in the tubing.31 This volume is not delivered to the patient’s lungs, but some fraction of it may be measured by a spirometer within the circuit, adding a form of apparatus dead space to the system. The exact fraction depends on where the spirometer is placed in the circuit with respect to the unidirectional valves.

TABLE 4-1

Compliance of Ohio Anesthesia Breathing Circuits

From Fluidically controlled anesthesia ventilator operation and maintenance manual. 1974, Ohio Medical Products (now GE Healthcare, Waukesha, WI).

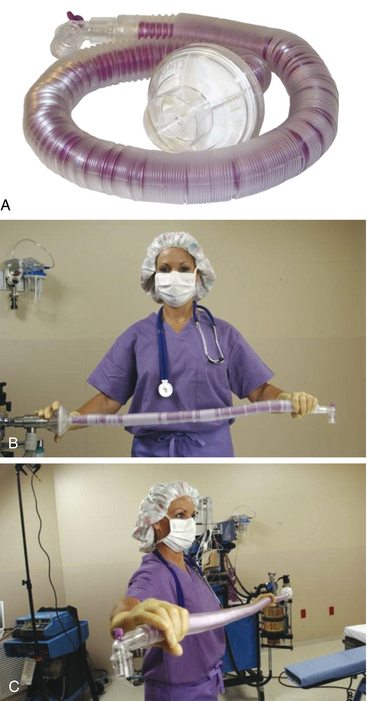

Resistance to gas flow in standard, corrugated breathing tubes is exceedingly small—less than 1 cm H2O/L/min of flow.32 When it is desirable to have the anesthesia machine at some distance from the patient’s head, several tubes may be connected in series with connectors 22 mm (⅞ inch) in outside diameter (OD). Alternatively, extra-long tubing is available, including tubing that can be compressed to 200 mL of volume in approximately 50 cm of length or that can be stretched to nearly 2 m with an 800-mL volume. These “concertina” extensions do not increase the resistance of the system by any appreciable amount and affect the apparatus dead space only by their compliant volume (Fig. 4-3).

FIGURE 4-3 “Concertina” style breathing circuit tubes can be or compressed (A and B) or stretched (C) to change in length and volume without significantly affecting apparatus dead space. (Courtesy King Systems, Noblesville, IN.)

The pattern of gas flow through the circuit is almost always turbulent because of the corrugations in the tubing, which promote both radial mixing and longitudinal mixing. In documenting performance of one circuit, Spoerel33 demonstrated complete mixing of dead space and alveolar gas after gas had passed through 1 m of such tubing. A change in gas composition at one end, such as when the delivered gas is altered at the anesthesia machine, completes a change in the inspired concentration at the patient connection within two to three breaths. The change in inspired concentration is nearly exactly the change in delivered concentration when high fresh gas flows are used (≥10 L/min). The change decreases to nearly imperceptible as inflow is decreased toward that of closed systems.

Lengths of breathing tubing are sometimes used to connect ventilators to the bag mount and to connect to scavenging devices. Optimally, either a 19- or 30-mm diameter ends on the scavenger mounts prevent inappropriate connections. Tubing of smaller diameter is made for use in circle systems designed specifically for infants and children, and their resistance to gas flow is insignificantly increased. With less compression volume, measured ventilation is more accurate.

Reusable rubber tubing is connected to the mask or tube by a separate Y-piece. Disposable sets often incorporate a Y that may or may not be detachable. Such a Y may be rigid, and it may incorporate an angle elbow or a pair of swivel joints. Although the swivel joints are convenient, they offer a greater chance of leaking; most connectors have negligible leakage, but those with swivels are twice as likely to leak.34 Any circuit should be tested before use by determining the oxygen inflow required to maintain 30cm H2O of pressure in the circuit (see also Chapter 32).

Unidirectional Valves

Unidirectional valves are incorporated into a breathing circuit to direct respiratory gas flow. They are commonly disks on knife edges or rubber flaps or sleeves. The essential characteristics of respiratory valves in breathing circuits are low resistance and high competence.35,36 The valves must open widely with little pressure and must close rapidly and completely with essentially no backflow.

Circle and nonrebreathing systems use two nearly identical valves: the inspiratory valve opens on inspiration and closes on expiration, preventing backflow of exhaled gas in the inspiratory limb. The expiratory valve works in a reciprocal fashion to prevent rebreathing. These valves can be mounted anywhere within the inspiratory and expiratory limbs of the circuit. The only critical feature of their location is that one must be placed between the patient and the reservoir bag in each limb. Properly positioned and functioning, they prevent any part of the circle system from contributing to apparatus dead space.37 Thus the only apparatus dead space in such a circuit is the distal limb of the Y-connector and any tube or mask between it and the patient’s airway. The respiratory valves on most modern anesthesia machines are located near, or incorporated into, the carbon dioxide absorber canister casing along with a fresh gas inflow site and excess gas (pop-off) valve. In the past, unidirectional valves have been incorporated into the housing of the Y-piece to decrease the apparatus dead space effect of compliance volume, but they have fallen into disfavor because of the weight they add to the mask. More importantly, they cause an obstruction to respiration if they are accidentally incorporated backward to the conventional valves in the circle.38 When valved Y-pieces were used, it was recommended that circle system valves be removed. Failure to reinsert the circle system valves when a normal nonvalved Y-piece was used has caused needless complications.

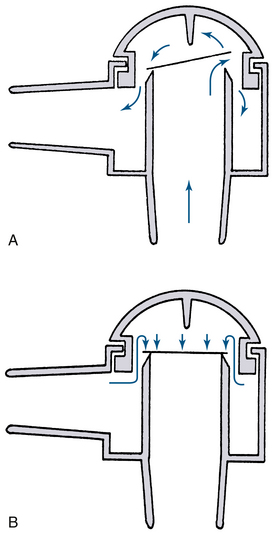

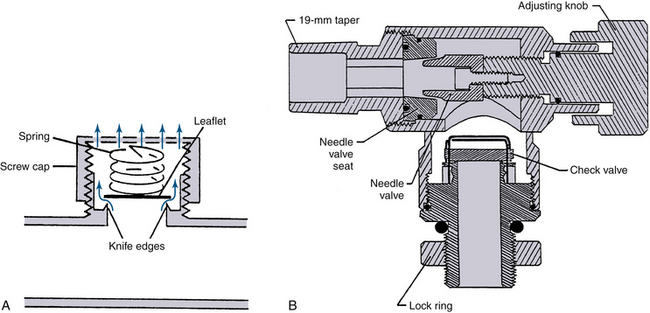

The common valves in anesthetic circuits are dome valves consisting of a circular knife edge occluded by a very light disk of slightly larger diameter (Fig. 4-4). The disk lifts off the knife edge when flow is initiated by the patient’s inspiratory effort, when positive pressure is applied to the reservoir bag, or when the ventilator bellows empties. The disk is contained either by a small cage or by the dome itself. It must be hydrophobic so that water condensation does not cause it to stick to the knife edge and thereby increase the resistance to opening. Most modern disks are made of hydrophobic plastic and are light and thin. When properly functioning, the disk in a unidirectional valve can be lifted with a circuit pressure of 0.31 cm H2O or less. Most unidirectional valves are mounted vertically, with the disk oriented horizontally, so that it will fall properly into the closed position and seal the circuit from backflow. The valve disks also can be oriented vertically, as on the absorber block of the Datex-Ohmeda ADU workstation (GE Healthcare, Waukesha, WI; see Fig. 4-4, D). Failure to seal converts a large volume of the circuit into apparatus dead space, resulting in rebreathing. The top of the valve is covered by a removable clear plastic dome so that the disk can be easily seen and periodically cleaned or replaced.

FIGURE 4-4 A, Typical dome valve incorporated into a circle absorber housing. The valve is in the open position with gas flowing. B, Because of backpressure, the plastic disk seats on the knife edge and the valve is closed. C, One-way valves on the Datex-Ohmeda machine (GE Healthcare, Waukesha, WI). D, Datex-Ohmeda ADU absorber block showing unidirectional valves mounted vertically. (Courtesy K. Premmer, MD.)

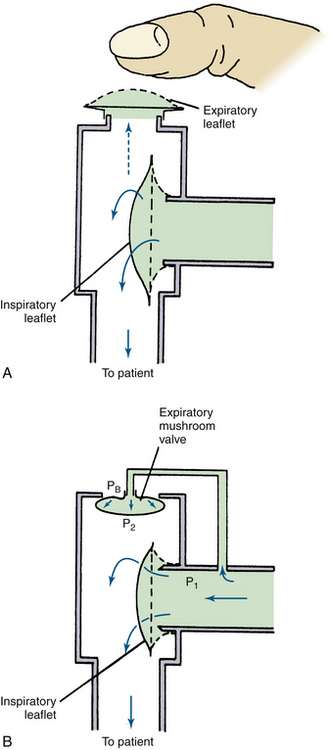

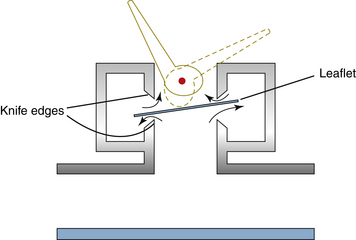

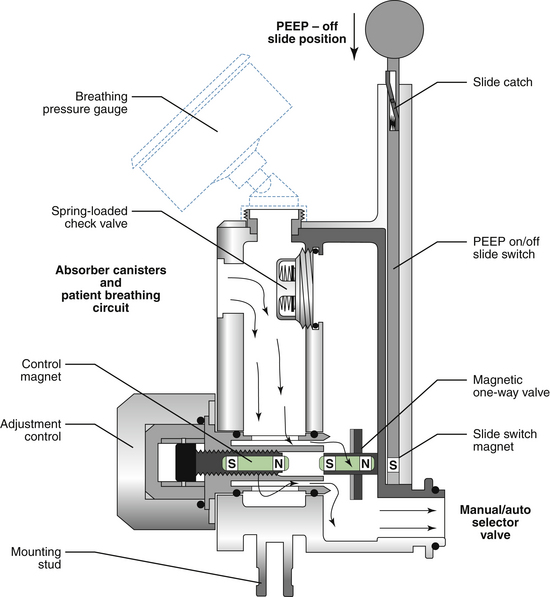

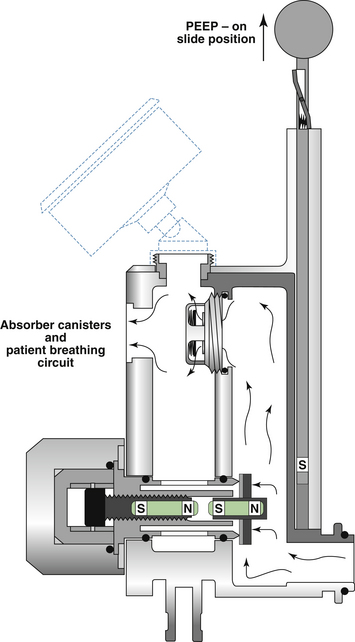

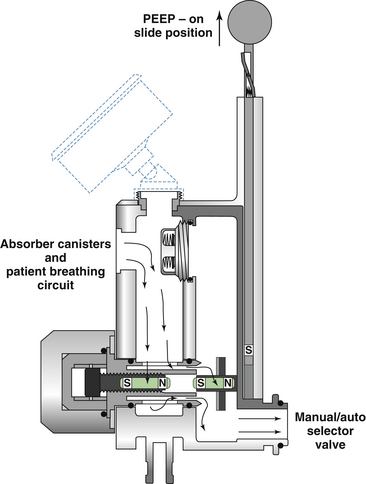

A nonrebreathing system requires two appropriately placed one-way respiratory valves (Fig. 4-5). Nonrebreathing valves permit the patient to inspire fresh gas from a reservoir and exhale alveolar gas into the room or into a scavenger. Such valves usually consist of a pair of leaflets in the same housing: one opens during inspiration, the other opens during expiration. The early nonrebreathing valve designs, such as the Digby-Leigh or Steven-Slater, required the anesthesiologist to occlude the expiratory valve with a finger if assisted or controlled ventilation was needed (Fig. 4-5, A).9,24 Modern designs that use springs, magnets, or flaps automatically close the expiratory valve when respiration is controlled.39-44 Other designs use the pressure difference across the inspiratory valve to inflate a mushroom-shaped balloon (Frumin) valve (Fig. 4-5, B),11 or to depress a dome-shaped cover on the expiratory (Fink) valve.6 Resistance is negligible in both designs, but the Frumin valve has the marked advantage of collapsing if the inspiratory supply is inadequate, permitting inspiration of room air. The Frumin valve also is lighter and more compact than the others. Some nonrebreathing valves are position sensitive and must be vertically oriented to function properly.45 Those that use flexible rubber leaflets or collapsible rubber tubing to provide the sealing function are not positional. Most nonrebreathing valves connect to masks and/or tracheal tubes, but a valve can be built into a mask.44

FIGURE 4-5 These nonrebreathing valves incorporate two leaflets that open alternately on inspiration or expiration. A, In the simplest form, the valve functions well during spontaneous ventilation (solid arrows), but an attempt to inflate the patient’s lungs manually blows open both inspiratory and expiratory leaflets (dotted arrow) unless the anesthesiologist simultaneously occludes the expiratory valve with a finger. Several nonrebreathing valves have been designed to overcome the necessity for manual assistance of valve function. B, Whenever gas flow opens the inspiratory leaflet, the pressure at point P1 is greater than at point P2 or PB. This pressure difference inflates the mushroom-shaped expiratory balloon, sealing the expiratory limb. If no gas is supplied to the inspiratory limb, spontaneous effort on the part of the patient lowers both P1 and P2 well below atmospheric pressure (PB) so that the mushroom valve collapses and the patient inspires room air.

Self-inflating resuscitators for air or air-oxygen mixtures use similar pairs of valves to control gas flow.10,46,47 The Ruben valve has an expiratory bobbin-shaped structure that, when open, occludes the inspiratory limb (Fig. 4-6). Anesthetic vapors and secretions tend to expand this bobbin slightly, causing it to jam.47 Such resuscitator valves should not be used in anesthesia, nor should they be used for transporting patients who are still exhaling anesthetic agents.

Breathing Bags

Breathing bags, also known as reservoir bags or counterlungs, have three principal functions: 1) they serve as a reservoir for anesthetic gases or oxygen, from which the patient can inspire; 2) they provide the means for a visual assessment of the existence and rough estimate of the volume of ventilation; and 3) they serve as a means for manual ventilation. A reservoir function is necessary because anesthesia machines cannot provide the peak inspiratory gas flow needed during normal spontaneous inspiration. Although the respiratory minute volume of an anesthetized adult is rarely more than 12 L/min, the peak inspiratory flow rate may reach 50 L/min, with 20 L/min not uncommon. For example, assume a patient is breathing at a rate of 20 breaths/min with a tidal volume of 500 mL and a minute volume of 10 L/min. If the inspiratory to expiratory ratio (I:E) is 1:2, each breath takes 1 second for inspiration and 2 seconds for exhalation. The tidal volume of 500 mL inspired in 1 second is an average inspiratory flow (volume per unit time) of 500 mL/sec or 30 L/min. This is many times greater than the commonly used fresh gas flows. The peak flow in mid-inspiration may be 30% to 40% higher.

Assessment of the presence and volume of spontaneous ventilation is affected by the fresh gas flow. In low-flow techniques, virtually all the gas inhaled by the patient comes from the reservoir bag, and its excursion thus reflects tidal volume. If the fresh gas inflow rate from the machine exceeds 10 L/min, most of the gas inhaled by the patient comes from the fresh gas supply, and the reservoir bag shows little excursion. In a spontaneously breathing patient with a circuit gas inflow rate of 6 L/min, nearly half the tidal volume comes from the fresh gas inflow, halving the apparent tidal volume as indicated by movement of the bag.

Reservoir bags for anesthesia machines usually are ellipsoid so they can be easily grasped with one hand. They are made of nonslippery plastic or latex in sizes from 0.5 to 6 L. To improve grip, some have an hourglass shape or a textured surface; nonlatex bags are available for use with patients who have a latex sensitivity. The optimally sized bag can hold a volume that exceeds the patient’s inspiratory capacity; that is, a spontaneous deep breath should not empty the bag. For most adults, a 3-L bag meets these requirements and is easy to grasp. Bags with a nipple at the bottom for use as an alternate pop-off site are available but are rarely used.

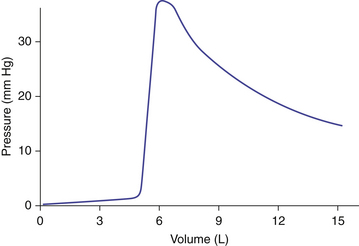

In circle systems, the breathing bag usually is mounted at or near the carbon dioxide absorbent canister via a T-shaped fitting, usually near the pop-off valve. The bag also may be placed at the end of a length of corrugated tubing leading from the T-connector to provide some freedom of movement for the anesthesiologist. The pressure-volume characteristics of overinflated bags become important if the pop-off valve is accidentally left in the closed position and gas inflow continues (Fig. 4-7). Rubber bags become pressure limiting with maximum pressures of 40 to 50 cm H2O, although prestretching may favorably lower the maximum distending pressure.48-50 Disposable bags may reach twice the pressure of rubber bags and then rupture abruptly.

FIGURE 4-7 As an anesthesia reservoir bag is filled from its evacuated volume to its nominal volume, the pressure increases little; as the rubber is slightly stretched, however, a small increase in volume rapidly raises the pressure to some maximum, depending on the shape and wall thickness of the bag. Further increase in the bag’s volume causes a decrease in pressure. The falling pressure with rising volume follows Laplace’s law: P = 2T/r, where P is pressure, the constant T is a function of the bag’s thickness and material, and r is the radius.

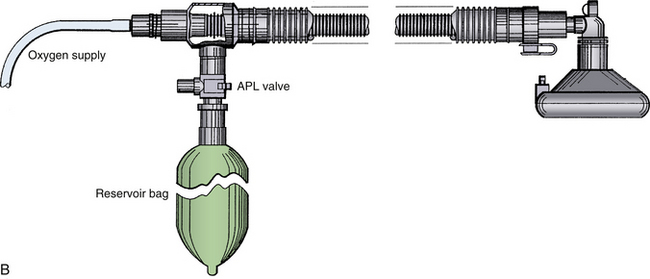

Gas Inflow and Pop-off Valves

Gases are delivered from the anesthesia machine common gas outlet to the circuit via thick-walled tubing connected to a nipple incorporated into the circuit. In circle systems this gas inflow nipple is incorporated with the inspiratory unidirectional valve or the carbon dioxide–absorbent canister housing. The preferred fresh gas inflow site is between the carbon dioxide absorber and the inspiratory valve. The location for other circuits depends on whether breathing is spontaneous, assisted, or controlled because the type of breathing influences the efficiency of carbon dioxide elimination.

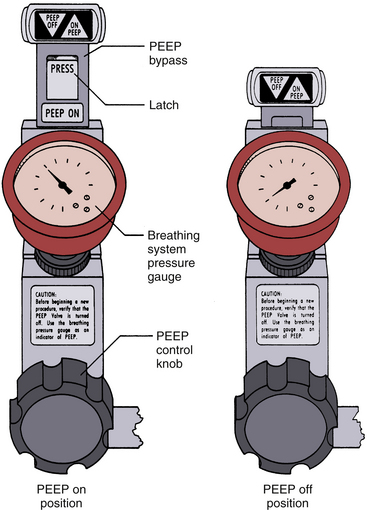

Pop-off valves—also known as overflow, outflow, relief, spill, and adjustable pressure-limiting (APL) valves—permit gas to leave the circuit, matching the excess to the inflow of fresh gas. The efficiency of an APL valve is related in part to the placement of the fresh gas inflow. There are many different designs, but most are constructed like a dome valve loaded by a spring and screw cap (Fig. 4-8). The valve should open at a pressure of less than 1 cm H2O. As the screw cap is tightened down, more and more gas pressure in the circuit is required to open it, permitting PEEP during spontaneous ventilation or pressure-limited controlled respiration. The number of clockwise turns from fully open to fully closed should be one or two: fewer turns make it difficult to set a desired circuit pressure accurately, whereas more make it tedious to use. The exhaust from any of the commonly used pop-off valves can be collected by scavenging system transfer tubing connected at this point.51

FIGURE 4-8 Adjustable pressure-limiting (APL) or “pop-off” valves. A, Spring-loaded design. When the cap is fully tightened down, the spring is compressed enough to prevent the valve leaflet from lifting at any airway pressure. When the top is loosened and the spring is not compressed, the valve opens at a pressure equal to the weight of the leaflet divided by its area, usually <1 cm H2O. B, The Dräger Medical (Telford, PA) APL valve design is an adjustable needle valve, the opening of which determines gas flow into the scavenger system. The check valve prevents reverse flow of gas from the scavenger into the patient circuit. C, A pop-off valve from a Dräger Apollo anesthesia workstation. This APL valve is similar to that in A and has approximate calibrations. (A and B, Courtesy Dräger Medical, Telford, PA. C, Courtesy K. Premmer, MD.)

The Datex-Ohmeda GMS absorber uses an APL valve similar in design to that shown in Figure 4-8, which basically is a spring-loaded disk. When the spring is fully extended, it exerts a pressure of approximately 1 cm H2O on the disk to hold the valve closed. This is necessary because the waste gas scavenging interface is connected downstream of the APL valve and transfer tubing. If an active scavenging system is used—that is, if suction is applied to the interface—the negative pressure could potentially be applied to the patient circuit (see Chapter 5). To prevent this, the Ohmeda scavenger interface uses a negative-pressure relief (“pop-in”) valve that opens at a pressure of −0.25 cm H2O to allow room air to enter the interface. Thus the greatest negative pressure needed to open the APL valve (−0.25 cm) is less than the least spring tension needed to keep the valve closed (~1 cm H2O). This arrangement, with the use of an active scavenging system, protects against application of excess negative pressure to the breathing circuit. In the fully closed position, the maximum spring pressure applied to the Datex-Ohmeda APL valve disk is 75 cm H2O. Thus, in the manual/bag mode, the circuit pressure in an Datex-Ohmeda breathing system is limited to 75 cm H2O. Note that in the ventilator mode, the circuit pressure is limited by high pressure-limit settings on the Datex-Ohmeda ventilator (up to 100 cm H2O with the Datex-Ohmeda 7800 and 7900 ventilators; see Chapter 6).

In Dräger Medical (Telford, PA) anesthesia delivery systems, the design of the APL valve differs from those described above (see Fig. 4-8, B). This design uses a needle valve instead of a spring-loaded disk, and adjusting the knob varies the size of the opening between the needle valve and its seat, which in turn adjusts the amount of gas permitted to flow to the scavenger system. A check valve prevents gas from the scavenging system from entering the breathing system. With this design, the needle valve can be totally closed; it therefore does not function as a true pressure limiter.

Special types of pop-off valves permit spontaneous or assisted respiration without tedious adjustment.40,52-54 The simplest is the Steen valve (Fig. 4-9), which essentially is two knife-edge valves of the dome type, one inverted over the other, that share a common disk.24 A relatively slow flow of gas during the latter part of exhalation, up to 10 L/min, lifts the valve disk at one side only so that the exhaled gas escapes around the disk. An abrupt increase in pressure lifts the valve vertically, seals it against the upper knife edge, and closes the circuit so that no gas is lost. The Georgia valve adds a light spring loading to the same design, which increases the range of gas flows it can exhaust; this is necessary for use with mechanical ventilators.55 Most current anesthesia ventilators have such an automatic pop-off valve built in so that gas is exhausted only at end exhalation (see also Chapter 6).

FIGURE 4-9 The Steen valve permits gas to exit from a circuit under the slight pressure that occurs during exhalation. However, a sudden rise in pressure, such as occurs during an assisted or controlled inhalation, seals the leaflet against the upper circular knife edge. A lever-operated eccentric cam defeats this effect if desired and turns the valve into an ordinary pop-off valve that is not spring loaded.

Carbon Dioxide Absorption

In partial rebreathing and nonrebreathing systems, carbon dioxide is vented to room air. When a closed system is used, however, the exhaled carbon dioxide must be otherwise removed. Carbon dioxide in the presence of water is hydrated to form carbonic acid. When carbonic acid reacts with a metal hydroxide, the reaction is one of neutralization that results in the formation of water and a metal bicarbonate or carbonate and the generation of heat. This reaction is used in anesthesia for carbon dioxide absorption.56 In the reactions shown below, only the molecular forms of the reactants are written. The reactions actually proceed by initial ionization in the thin film of water at the surfaces of the absorbent. In soda lime:

In barium hydroxide lime—or Baralyme, which is no longer being produced (see Chapter 30)—Ba(OH)2 replaces the NaOH and KOH in equations 4-2, 4-3, and 4-4, with BaCO3 the product.

Wet soda lime is composed of calcium hydroxide (~80%), sodium hydroxide and potassium hydroxide (~5%), water (~15%), and small amounts of inert substances such as silica and clay for hardness. The potassium hydroxide and sodium hydroxide function somewhat like a catalyst to speed the initial reaction, forming sodium and potassium carbonates. The sodium and potassium carbonates react over the course of minutes with the calcium hydroxide to form calcium carbonate and water, regenerating sodium and potassium hydroxides. Soda lime is exhausted when all the hydroxides have become carbonates. Soda lime can absorb 19% of its weight in carbon dioxide5; thus 100 g of soda lime can absorb approximately 26 L of carbon dioxide.

A novel carbon dioxide absorbent was created in 1999. Calcium hydroxide lime (Amsorb) is composed of calcium hydroxide (70%); a compatible humectant, calcium chloride (0.7%); and two setting agents, calcium sulfate (0.7%) and polyvinylpyrrolidine (0.7%), to improve hardness and porosity; and water (14.5%).57 By adding calcium chloride as a humectant, the calcium hydroxide remains damp and eliminates the need for sodium or potassium hydroxide. With removal of the strong alkali, calcium hydroxide lime has potential benefits that include decreased formation of compound A with sevoflurane use, minimal formation of carbon monoxide when exposed to desflurane or isoflurane, and minimal destruction of inhaled agents.58

Indicator Dyes

Organic dyes are added to soda lime and barium hydroxide lime to provide a visual indication of its state. As carbonate is formed from the hydroxide, the pH becomes less alkaline and the granules change color: ethyl violet changes from white to blue violet with exhaustion, ethyl orange from orange to yellow, and cresyl yellow from red to yellow. Ethyl violet is the dye most commonly used because the color change is vivid and of high contrast at a pH intermediate between NaOH and CaCO3. It can be bleached by intense light, but in the usual OR setting this is not a problem. A slight fading of color can be seen in the zone of active absorption when use stops. This so-called regeneration occurs where the lime is nearly exhausted of calcium hydroxide but has all alkaline hydroxides neutralized.

The color changes only because of the regeneration of a small amount of sodium and potassium hydroxide. At the next use, the expended nature of the soda lime rapidly becomes evident. There is no true regeneration of activity, and the color change of indicator lime is not to be relied on. The anesthesiologist must know what color change is expected of the absorbent being used, allow for the effects of regeneration, be cognizant of the effects of preferential gas flow at the surface between the smooth plastic canister and the irregular granules (channeling), and understand the effects of the fresh gas flows chosen based on how long a given charge of soda lime can be expected to last. No indicator or rules offer absolute predictions, but the use of capnometry to detect increasing inspired carbon dioxide remains the gold standard for assessing adequate carbon dioxide removal.

Mesh Size and Channeling

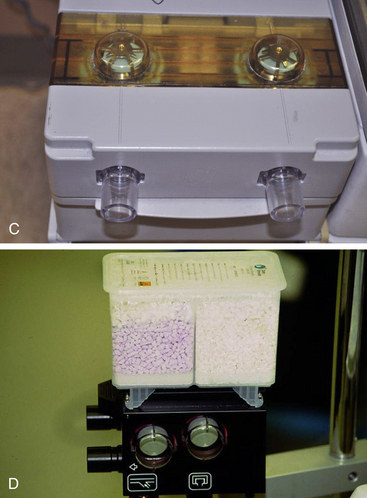

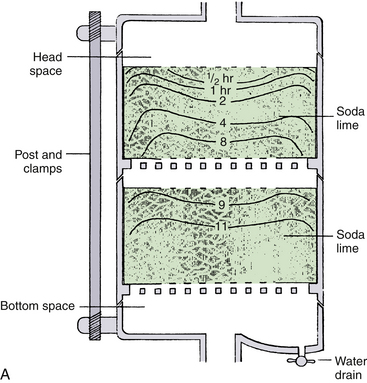

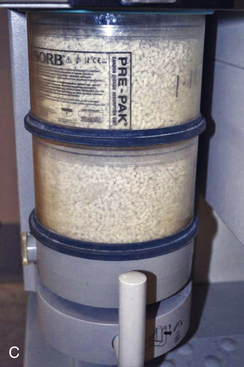

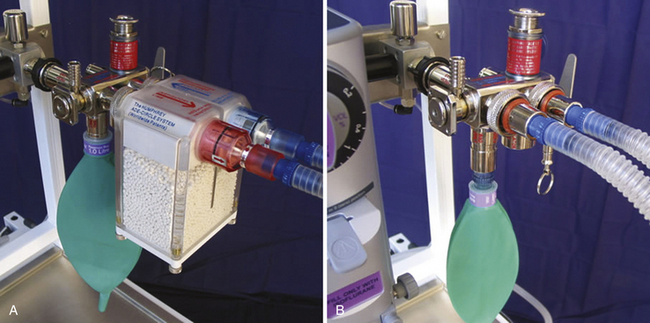

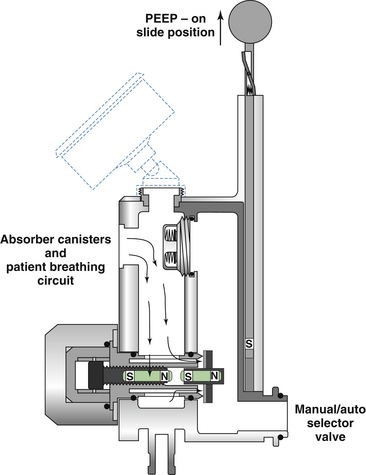

Soda lime is precisely manufactured to maximize its absorptive qualities and to minimize resistance to gas flow.5 The granules are sized 4 to 8 mesh (i.e., they will pass through a strainer having 4 to 8 wires per inch) and have a rough, irregular surface that maximizes the surface/volume ratio that facilitates the rapid diffusion of carbon dioxide through the pores to the voids within the granules.56,59-62 Approximately half the volume of a packed canister is gas. The gas volume of the voids is inversely proportional to the water content of the granules and is 1 to 2 times that of the volume between granules. Soda lime is supplied either in quart cartons that fill a canister, disposable canisters, or bulk containers ranging from 5 pounds to 5 gallons. The volume between granules can be reduced by overzealous packing at the risk of creating fine particles and dust that are irritating. Channeling, or flow moving preferentially along the sides of the canister and within the absorbent itself, was a problem with to-and-fro canisters that were often horizontal and improperly packed. This problem can be minimized by the use of baffles, placement so that gas flow is vertical, permanent mounting to avoid frequent canister movement, use of prepackaged cylinders, and avoidance of overly tight packing. Modern carbon dioxide–absorbent canisters (Fig. 4-10) follow the design of the Roswell Park absorber with double chambers to promote efficient use, circular baffles to minimize channeling, and mixing space at the top and bottom.19,56 Although most have clear plastic walls, some are tinged blue for the purpose of enhancing the appearance of color change in the indicator dye.

FIGURE 4-10 A, Schematic of modern carbon dioxide absorbent canister. Originated by Elam and Brown, these transparent twin-chambered canisters are now supplied by all producers. Permanently mounted with a vertical gas-flow axis, they eliminate dusting, channeling, and packing problems. Used as intended, changing the exhausted canister only when the second half is exhausted, they use the absorptive capacity of soda lime fully, as shown by the lines illustrating patterns of exhaustion. Drop-in, prepacked containers add convenience. The nearly standard shape is 8 cm high and 15 cm in diameter. Because water condensate may collect at the bottom and form a caustic lye solution with the dust, a drain valve is an important component. Convenience of opening, closing, and sealing varies with design, but most now have a single-action clamp mechanism. The casting for the top and bottom should be resistant to alkaline corrosion and may incorporate other components of the breathing circuit (e.g., bag mount, inflow site, and valve housings. B, Prefilled single-chamber canister. C, Twin canister on Datex-Ohmeda Aestiva machine. (GE Healthcare, Waukesha, WI). (B and C, Courtesy K. Premmer, MD.)

Other Reactions with Absorbents

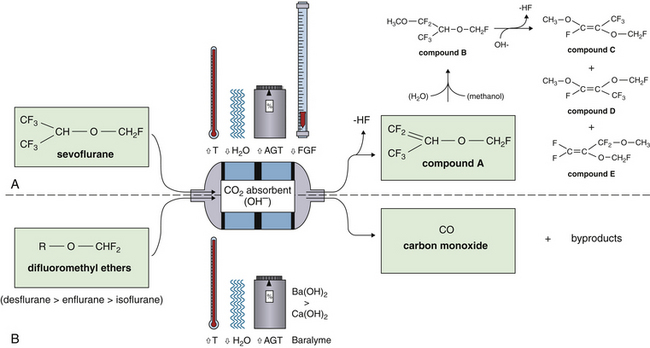

Sevoflurane did not gain U.S. Food and Drug Administration (FDA) approval for use until 1995 despite its use in Japan and elsewhere since the 1970s. When sevoflurane was first described, early testing revealed the production of fluoromethyl-2,2-difluoro-1-(trifluoromethyl) vinyl ether, better known as compound A, when sevoflurane is exposed to various alkalis, including soda lime.63 This reaction occurs when hydrogen fluoride is eliminated from the isopropyl moiety of sevoflurane. Concern arose over evidence that compound A is nephrotoxic—and, at higher concentrations, lethal—in rats.64-66 Although studies of the nephrotoxicity of compound A in humans have had conflicting results,67-69 sevoflurane has been administered with apparent safety for several years.68 What is clear is that certain factors related to the breathing system can contribute to the production of compound A during anesthesia with sevoflurane. These include increasing inspired sevoflurane concentration, increasing absorbent temperature, decreasing absorbent water content (desiccation), and a decreasing fresh gas flow rate.70,71 Hypotheses to explain the effect of low flows on compound A production include increased contact of exhaled gas with carbon dioxide absorbent, increased rebreathing of compound A, and increased absorbent temperature. Current sevoflurane labeling indicates that whereas a fresh gas flow from 1 to 2 L/min may be used safely for fewer than 2 minimum alveolar concentration (MAC) hours, flows less than 2 L/min should not be used for more than 2 MAC hours, and flows below 1 L/min are not recommended for any duration with this agent. The choice of absorbent, whether barium hydroxide lime or soda lime, does not seem to significantly influence production of compound A (Fig. 4-11).70,72

FIGURE 4-11 The degradation of volatile anesthetics by carbon dioxide absorbents. A, Production of compound A from sevoflurane is promoted by warmer, drier absorbent and by higher concentrations of agent (AGT) and lower fresh gas flows (FGF). In the presence of water, sevoflurane produces methanol, which promotes the breakdown of compound A into compound B and other low-toxicity products C, D, and E. B, The phenomenon of carbon monoxide (CO) production from the difluoromethyl ethers (desflurane, enflurane, and isoflurane) is often the result of prolonged high gas flows, which dry out the absorbent. Higher temperatures (T) and agent concentrations increase CO production in this setting, and the use of barium hydroxide lime (Baralyme) results in more CO production than the use of soda lime.

Desiccation of carbon dioxide absorbents is known to be related to another potential hazard, that of carbon monoxide production. The notion that carbon monoxide could be found in detectable amounts in anesthesia breathing circuits containing soda lime was first reported with the use of trichlorethylene and during closed-circuit anesthesia secondary to endogenous production.73 More recently, it has been recognized that difluoromethyl ethers in common use today, including desflurane and isoflurane, can liberate carbon monoxide during destruction of these agents by carbon dioxide absorbents.74 Difluoromethyl ethers are fluorinated volatile anesthetics that contain an –O–CHF2 moiety. Early case reports of unexplained carboxyhemoglobinemia during enflurane anesthesia pointed to an association with “first case on Monday morning” anesthetics75 or with older absorbents.76 This has been explained by invitro studies that revealed a marked association between dryness of the absorbent and production of carbon monoxide.74 It is theorized that high oxygen flows over the absorbent canister during the weekend, or after prolonged absorbent use, desiccate the absorbent. The type of anesthetic is important, with the order of carbon monoxide production being desflurane, which produces the most, followed by enflurane then isoflurane. Sevoflurane and halothane lack an –O–CHF2 moiety and do not appreciably produce carbon monoxide in the presence of carbon dioxide absorbents. Barium hydroxide lime seems to cause greater carbon monoxide liberation than does soda lime, but both absorbents produce more carbon monoxide with increasing temperatures and with increasing concentrations of anesthetic.74 Recognition of the presence of carbon monoxide in an anesthesia breathing circuit in which desflurane or isoflurane is being used may be facilitated by the use of a multiwavelength pulse oximeter (pulse CO-oximeter; see Chapter 11) that can continuously measure carboxyhemoglobin. Such devices are available and used in emergency departments but are not yet widely used in the operating room.77-78 It is recommended that absorbent that is known or suspected to be desiccated not be used, especially with desflurane, isoflurane, or enflurane. The FDA recommends replacement of any absorbent suspected of contributing to the presence of carbon monoxide in the breathing circuit, although some investigators have suggested rehydration of existing absorbent as a practical and more cost-effective alternative.79

Alternatives to soda lime are available. For example, lithium hydroxide offers a little more carbon dioxide absorption capacity per unit of volume but more than three times per unit of weight; it is therefore used in submarines. Barium hydroxide lime contains 20% Ba(OH)2 and little alkali. Its dust is slightly less alkaline when dissolved in water, and it is a suitable alternative to soda lime.80 The end products are barium carbonate and calcium carbonate. It is initially pink but turns blue-gray with exhaustion because of two indicator dyes, Mimosa Z and ethyl violet. Barium hydroxide is as efficient as soda lime per unit of volume, but because of its density, it is half as efficient per unit of mass.

Methods of carbon dioxide removal other than chemical reaction with metal hydroxides have also been investigated. Much of the research in this area has originated from aviation, space, and submarine technology. One method of particular interest is a molecular sieve that uses synthetic zeolites, crystalline hydrated aluminosilicate materials, arranged in a three-dimensional tetrahedral framework that contains entry pore sites and cavities.81 Gases that enter the sieve separate on the basis of size and polarity. Carbon dioxide is a polar molecule and is retained in certain zeolites by the action of Van der Waal forces. Because chemical bonding does not take place, the process can be reversed by slight changes in pressure and temperature, thus allowing regeneration of saturated zeolite. This technology has already been used extensively in industry for petroleum refining, water purification, and drying of gases and liquids. It has also been used for aviation and medical purposes in oxygen generators.82,83 Advantages suggested for the use of molecular sieves in anesthesia breathing systems include lack of compound A in the presence of sevoflurane, avoidance of carbon monoxide production, removal of nitrogen dioxide in circuits that deliver nitric oxide, and cost savings as a regenerative process.84,85

Mixing Devices

Resistance to gas flow in a modern circle system is less than 1 cm H2O/L/min of gas flow, one half of a person’s normal airway resistance to gas flow.35,36 Patients, including infants and children, may safely breathe spontaneously from a circle system for prolonged periods. However, before circuit designs permitted such low resistances, attempts were made to decrease resistance to breathing by providing a continuous flow of gas around the circle, thereby causing the inspiratory and expiratory valves to float open rather than open and close with each breath. Both pumps and Venturi devices driven by fresh gas flow were designed, the most prominent of which was the Revell circulator.86,87 Although these devices can decrease dead space and resistance in the apparatus, the potential benefit is slight; in some circumstances these devices can backfire, actually increasing the work of breathing. If the low resistance of modern equipment is still a concern, it can be eliminated by controlled ventilation. Ways to reduce the mean airway pressure during controlled ventilation have been suggested but are not commonly used.88

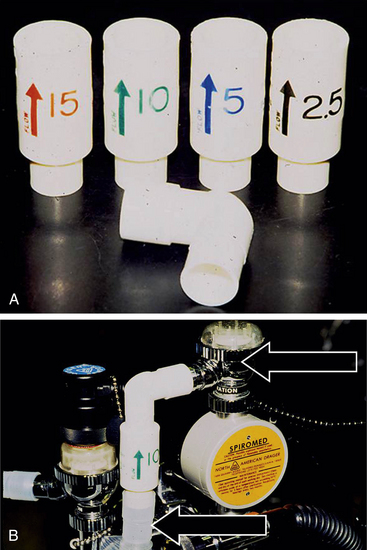

Mixing of the expirate is required to measure carbon dioxide production and physiologic dead space. Standard physiologic testing usually collects all the expired gas for several minutes to mix and measure the mixed expired gas concentrations needed in these calculations (see also Chapter 8). Simply averaging a continuous capnogram will not do; this yields a time-weighted average instead of the required volume-weighted average. To understand the difference, consider what happens toward the end of a respiratory cycle. While the carbon dioxide is increasing slightly, the flow is rapidly decreasing and may become zero at the end-expiratory pause. Carbon dioxide excretion should be the integral of concentration with respect to flow; when flow falls to zero, so does carbon dioxide excretion, but the increased end-tidal value continues to increase the time-weighted integral of the capnogram. Special volume mixing devices can be used, but suitable sites for such measurements may include the breathing bag, the ventilator bellows, or the expiratory port of the ventilator pressure relief valve at its connection with the scavenging system.

Bacterial Filters

There is little doubt that anesthesia breathing systems are susceptible to contamination from the patient and the environment.89 What is less clear is what risk this poses to subsequent patients and whether bacterial filters are necessary. Despite a recent resurgence of interest, in part related to a hepatitis C outbreak among patients sharing a common breathing system in an OR in New South Wales in 1993,90 an international consensus on the use of bacterial filters in anesthesia systems remains elusive. However, the American Society of Anesthesiologists concludes in its recommendations for infection control that a “bacterial filter with an efficiency rating of more than 95% for particle sizes of 0.3 µm should be routinely placed in the anesthesia circuit, where it will protect the machine from contamination with airborne infectious diseases.”91

Multiple invitro studies of various filters have demonstrated bacterial filtration efficiencies (BFEs) in the range of greater than 99.9% and viral filtration efficiencies (VFEs) of 96.43% to 99.84%.89 These efficiencies are achieved in the myriad commercial filters now available by the use of one of two fiber arrangements. The first consists of a small-pore compact matrix with a high airflow resistance offset by pleating to create a larger surface area. The second is a less dense, larger pore size arrangement that has less resistance to accommodate a smaller surface area. Some filters possess a permanent electrical polarity designed to enhance the Van der Waal forces that hold organisms within the matrix. Some are also considerably hydrophobic, which prevents water penetration and subsequent increased resistance and loss of efficiency. A few have combined roles as filters and heat and moisture exchangers (HMEs). These filters generally are placed at the Y-piece and serve as both an inspiratory and expiratory barrier, whereas standard filters usually are placed on the expiratory limb.

Considering the favorable evidence regarding filtration efficiency, the question of whether to use filters might be simpler if they were free of problems. Complications reported with the use of breathing system filters are in general related to either obstruction or leakage. Obstruction has been described when filters become saturated with circuit humidity as a result of sputum,92,93 edema fluid,94 nebulized aerosols,95 or malpositioning of the filter.96 In one case, a leak in the housing of a gasline filter resulted in patient hypoxia.97 Another consideration is cost; at least one author advocates the use of disposable or autoclavable circuits, carbon dioxide absorbers, and ventilator bellows—all components in contact with the patient’s breathing circuit—based in part on cost advantage because filters become unnecessary.98 Also of concern is the lesser efficiency of bacterial filters with regard to viruses. After discussing the efficiency of bacterial filters and the low likelihood of cross-contamination during their use, Hogarth,89 in his excellent review of the subject, concludes that “the use of filters within the breathing system adds a known risk to the patient, against which must be balanced the unknown risk of viral contamination and cross-infection by agents both known and unknown.”

In addition to bacterial filters, the breathing circuit also may incorporate a spirometer to measure ventilation, a humidifier to provide warmth and moisture, sampling sites for gas analysis, and scavenging devices to control atmospheric contamination by waste gases in the OR. These subjects are discussed in Chapters 5, 7, 8, 9, and 20.

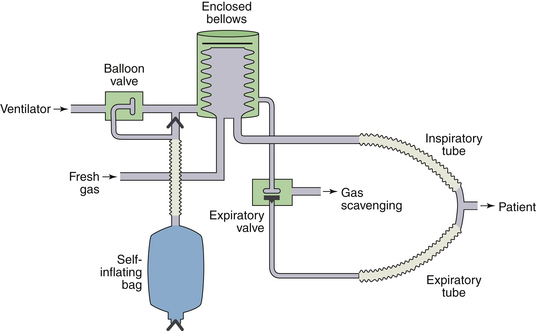

Analysis of Specific Circuits

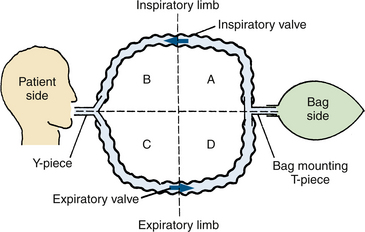

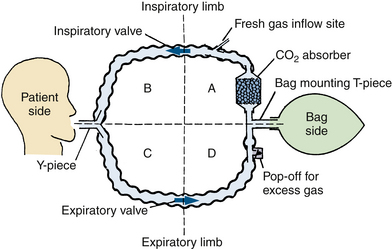

The basic components of a circle breathing system are an inspiratory and expiratory limb, each with a unidirectional valve, and a reservoir bag or counterlung that moves reciprocally with the patient’s lungs. The system may be divided into quadrants (Fig. 4-12). The patient and counterlung, but not the absorber, separate the inspiratory and expiratory limbs of the system; the valves separate the patient from the bag side of the system. The position of the valves within the limbs is not necessarily fixed; they may be anywhere between the patient and the bag with little practical difference in function. They usually are incorporated with the bag mount, pop-off valve, and absorber for manufacturing ease and durability. Even if the valves are moved to other locations, it is convenient to think of four quadrants when analyzing circle systems.

FIGURE 4-12 The four quadrants of a basic circle system. Two corrugated breathing tubes connect the patient and the counterlung (a bag or a ventilator bellows). One-way valves are located in the inspiratory limb and in the expiratory limb. The circle is therefore bisected twice, dividing it into four quadrants: A, B, C, and D. To make a practical circuit for anesthesia, three more essential components must be added: a fresh gas inflow site, a pop-off valve, and a carbon dioxide absorber.

For practical anesthesia, it is necessary to add three other components: a carbon dioxide absorber, a fresh gas inflow site, and a pop-off valve for venting excess gas. Each of the three may be placed in any of the four quadrants. There are hundreds of different ways to place three components in four quadrants, but only a few are used.99 Different manufacturers have used different arrangements, and older designs allowed the user to change the configuration with slight change in function. The optimal configurations for spontaneous and controlled ventilation are different,18 and most current designs are optimal for controlled ventilation.

This analysis emphasizes a frequently overlooked or misunderstood point: The bag, not the absorber, is on the opposite side of the circle from the patient. Most schematics and diagrams of breathing circuits perpetuate this misconception by showing symmetrical circuit limbs on either side of the absorber. The position of the bag is at neither the inspiratory limb nor the expiratory limb; rather it separates the two.37

Placement of the Carbon Dioxide Absorber, Fresh Gas Inflow, and Pop-off Valve

The carbon dioxide absorber may be placed in any of the four quadrants but is almost invariably placed in the inspiratory limb on the bag side so that apparatus resistance to inspiration may be overcome with assisted or controlled ventilation (Fig. 4-13). Placement on the expiratory side (Foregger circles) adds a mild degree of expiratory resistance that, like PEEP, may be beneficial for oxygen exchange but increases the risk of barotrauma. A bypass valve to permit carbon dioxide to build up was considered desirable by a majority of anesthesiologists but not by those who build the apparatus.100 The carbon dioxide absorber is absolutely necessary in a low fresh gas flow technique because no other method is available to remove carbon dioxide; that is, it is removable neither by dilution nor exclusion from reinspiration. As fresh gas flow is increased above gas uptake rates, the other methods become increasingly effective. This is noted by the anesthesiologist as longer intervals before the indicator in the absorbent suggest that it be replaced. At a 5 L/min fresh gas flow, the absorbent lasts more than twice as long as at 500 mL/min. This is not cost effective because the extra anesthetic gases and vapors cost more than the absorbent saved. In addition to saving on agents, the absorbent has two other beneficial effects: both expired humidity and heat are partially conserved, and both are optimized as flow decreases.101,102 The risks of absorbent (e.g., soda lime) include airway reaction to inspired alkaline dust, which can be minimized by good design and technique; alkaline “burns” from condensed water and/or dust spilled from the canister housing; and a breathing circuit with more connections and pieces, which provides more opportunity for user error.

FIGURE 4-13 Placement of the carbon dioxide absorber, fresh gas inflow, and pop-off valve. The typical site for the absorber is in the inspiratory limb on the bag side, that is, in quadrant A. The inspiratory valve typically is mechanically attached to the canister but is shown here as it was in Figure 4-12 for ease of analysis. Fresh gas inflow usually is on the bag side in the inspiratory limb (quadrant A), downstream from the carbon dioxide absorber. The pop-off valve typically is downstream from the expiratory valve, near the bag. It is shown here in quadrant D but could be in A, before the carbon dioxide absorber.

Although the inflow site for fresh gas may be physically placed in any of the four quadrants, efficiency and manufacturing convenience also are factors in placement.18,103 The inflow site usually is incorporated with the other components; that is, the absorber, bag mount, and valves. If the inflow site is located on the patient side of the inspiratory valve (quadrant B, Fig. 4-13), gas flows continuously around the circle throughout the respiratory cycle. Thus spirometry in the expiratory limb is inaccurate unless total gas flow is shut off.104 If inflow is located on the patient side of the expiratory valve (quadrant C, Fig. 4-13), any carbon dioxide–containing alveolar gas between the Y-piece and the patient is washed into the patient’s lungs during inspiration at the rate of the fresh gas flow. This may be negligible during closed-system anesthesia, but it can produce rebreathing of up to half of the previously exhaled alveolar gas at total flows of 10 L/min. Placement in quadrant D is simply inefficient because some fresh gas will be lost to the pop-off valve in most circles.

Recommended placement for the fresh gas inflow is on the bag side of the inspiratory limb between the inspiratory valve and absorber (quadrant A, Fig. 4-13). If the absorber housing has appreciable head space, as is common, this inflow site stores the continuously delivered fresh gas during exhalation. Gas flows down the inspiratory limb only during inspiration. During exhalation, fresh gas flows backward toward the absorber, bag, and pop-off valve. Thus fresh gas provides most of or all the respired gas with high-flow techniques, or it enriches the oxygen and anesthetic-depleted expiratory gas with low-flow techniques.

The pop-off valve may be placed anywhere in the circle, but some locations are more rational than others. Locating the valve in the inspiratory limb (quadrants A and B, Fig. 4-13) tends to vent fresh anesthetic and carbon dioxide–free gas. Furthermore, locations in the inspiratory limb on the patient side (quadrant B) permit some carbon dioxide–containing exhaled gas to enter the inspiratory limb during the end of a spontaneous breath. This rebreathing is clearly undesirable. It is mechanically convenient to place the pop-off valve between the expiratory valve and the bag mount, or opposite the bag mount, before the absorber (i.e., in quadrants D or A, but close to the bag mount). Incorporating the pop-off valve into a one-piece absorber/bag mount/expiratory valve/pop-off valve assembly provides convenience and durability.

There is at least theoretic value to locating the pop-off valve on the patient side at the Y or next to it (quadrant C, Fig. 4-13). During spontaneous inspiration, the pressure at this site is below atmospheric pressure and the pop-off valve is closed. During exhalation, the pressure is just slightly above atmospheric pressure, and gas flows to the reservoir bag until it is distended to its nominal volume. Then the pressure in the entire circuit increases as fresh gas inflow and exhalation from the patient continue, opening the pop-off valve. The gas vented is primarily carbon dioxide–rich, oxygen-depleted, and anesthetic-depleted end-tidal gas. However, the situation is reversed during assisted or controlled ventilation. During inspiration, the pressure in the circuit at the Y-piece is positive with respect to atmospheric pressure. A pop-off valve located at the Y-piece would dump fresh gas, and one near the bag would dump a mixture of dead space gas and end-tidal gas. Two pop-off valves on the same circuit double the risk of hypoventilation when ventilation is changed to manual because the anesthesiologist may fail to close both valves. For this reason, pop-off valves at the Y-piece are no longer used.

Flow and Concentration

The gas mixture inspired by a patient breathing from a circle system is determined by the fresh gas inflow, the configuration of the circle, the respiratory pattern, and the uptake by the patient of oxygen and anesthetics. At fresh gas inflow rates that exceed minute ventilation, the circle behaves similar to a nonrebreathing system. The concentration of inspired gas closely approaches that being delivered from the gas flowmeters on the machine. As flow is progressively decreased, a disparity between fresh gas inflow and actual inspired concentration of anesthetics increases.

In a closed system, in which inflow matches loss from the system, the composition of reinspired gas is not predictable from the inflow concentration of gases.105 Inspired and exhaled gases differ because of uptake of oxygen and anesthetic and excretion of carbon dioxide. Oxygen concentration in mixed exhaled gas usually is 4% or 5% lower than that in inspired gas. Although oxygen uptake remains relatively constant during anesthesia (approximately 250 mL/min standard temperature and pressure dry [STPD]) in the average adult, provided that body temperature does not change appreciably, anesthetic uptake varies; it is greatest at the start of anesthesia and decreases with time. If oxygen concentration is maintained constant during closed-system anesthesia, the flowmeter values reflect oxygen consumption and anesthetic uptake by the patient rather than inspired concentrations. When nitrous oxide is used in closed-system anesthesia, the oxygen tension or concentration in the circle must be continuously monitored because nitrous oxide uptake declines but oxygen uptake does not. The inspired gas mixture may become hypoxic if the nitrous oxide inflow is not gradually decreased. Whether it is necessary to measure the concentration of potent volatile anesthetics during closed-system anesthesia remains controversial. Some believe that it is necessary, and others prefer to monitor anesthetic depth and patient responses clinically (see also Chapter 26).

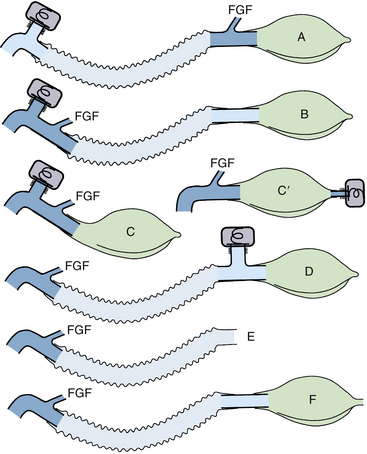

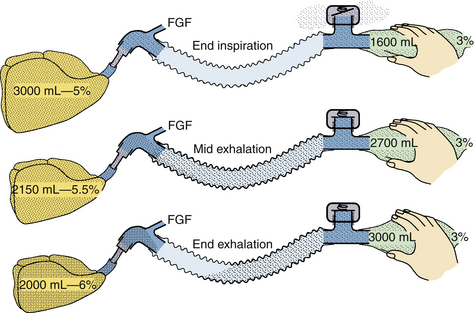

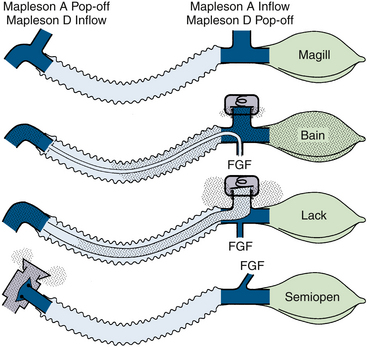

Semiclosed Systems: Mapleson Classification

Mapleson configurations of Magill circuits are characterized by a reservoir that can be filled by fresh gas, exhaled gas, or both. They may or may not have a pop-off valve, but if one is present it does not prevent rebreathing. Carbon dioxide, eliminated by both dilution with fresh gas and by efficient arrangement of the circuit components, is critically affected by total fresh gas flow and the pattern of respiration. The pattern of respiration includes the respiratory rate, tidal volume, dead space, I:E ratios, and inspiratory and expiratory flow patterns. The earliest semiclosed systems consisted of a bag attached to a mask by an elbow or a length of breathing tubing if it was desirable to move the large bag away from the face. The inlet for fresh gas was through a nipple on the elbow or through the tail of the bag, and a pop-off valve was placed either at the bag’s tail or at the elbow. The bag ideally contained a volume approximating the patient’s inspiratory capacity, about 3 L in an adult, to permit spontaneous deep breaths without the feeling of suffocation. Gas flows totaling 1 to 2 times the minute volume were used.8,101 Mapleson organized the various configurations into five typical models and later added a sixth (Fig. 4-14).7,26 Each of these breathing systems may be thought of as part of the continuum shown in Table 4-2.

TABLE 4-2

Spectrum of Carbon Dioxide Elimination

| Maximum Carbon Dioxide Elimination | To | Maximum Carbon Dioxide Retention |

| No mixing of fresh and alveolar gas occurs. | Complete mixing of fresh and alveolar gas occurs. | No missing of fresh and alveolar gas occurs. |

| Fresh gas goes to the patient. | The mixture is inhaled. | Alveolar gas is rebreathed. |

| Alveolar gas goes to the pop-off valve. | Fresh gas and mixed gas are “popped off” simultaneously. | Fresh gas goes to the pop-off valve. |

| DESIRABLE | ACCEPTABLE | UNDESIRABLE |

FIGURE 4-14 Mapleson classification of breathing systems. Note that the semiclosed systems (top four) contain most of the components of a circle system: tubing, connectors, bag, fresh gas inflow (FGF), and pop-off site. They lack carbon dioxide absorbers because carbon dioxide is lowered by the addition of fresh gas and elimination of carbon dioxide–rich gas preferentially through the pop-off valve. They also lack separate inspiratory and expiratory limbs; one tubing serves both purposes. The Mapleson A system (Magill attachment) is optimal for spontaneous respiration. The Mapleson C system is a simple bag and mask. Moving the pop-off to the bag tail is a major improvement (Cʹ), because this permits more mixing of fresh and exhaled gas than the Mapleson C (this modification, not one of Mapleson’s, has been added by the author). The B circuit is wasteful of fresh gas in both spontaneous and controlled respiration. The D circuit is similar to the A except that it exchanges the inflow and pop-off sites. A is optimal for spontaneous breathing, and D is best for controlled breathing. The Mapleson E system is essentially an Ayre’s T-piece with an added reservoir. If the reservoir is short, it is an open, not a semiclosed, system. This system is simple but lacks the convenience of a bag for ventilatory assistance or control. A bag can be added to it (F, or Jackson-Rees modification), which may or may not possess an adjustable pop-off valve to help assist or control ventilation. All these circuits share a common advantage. Vigorous hyperventilation cannot reduce the patient’s carbon dioxide tension much below normal if FGF is kept between one and two times the patient’s normal respiratory minute volume.

In Table 4-2, the far right situation represents complete rebreathing and is of use only in the study of respiratory control. The original Mapleson B and C configurations lie midway on the continuum and are judged to have no particular merit, except perhaps for brief procedures or to transport patients while supplemental oxygen is administered and breathing is augmented.

None of the Mapleson systems meets the requirements on the far left of Table 4-2, but with optimal configuration and high fresh gas flow, they may approach the function of an open system. Efficiency of the systems in this context can be translated as the lowest fresh gas flow that will ensure normal removal of carbon dioxide, thereby minimizing rebreathing. There is normally a partial pressure difference for carbon dioxide such that alveolar CO2 (PACO2) is greater than mixed expired CO2 (PECO2), which is greater than inspired CO2 (PICO2).

The most efficient configurations place the pop-off valve where the highest concentration of carbon dioxide is found during the phase of breathing in which the circuit pressure is above atmospheric pressure. This occurs at end expiration during spontaneous breathing and during inspiration with manually assisted or controlled breathing.

A great deal of attention has been devoted to determining the lowest gas flow that can be safely used in clinical anesthesia. A variety of claims have been made for the various circuits and for proprietary modifications of the circuits, such as Bain, Lack, Humphrey ADE, and Mera F circuits. Unfortunately much of the published work has one or more of the following flaws:

1. Theoretical analyses embody unrealistic assumptions about mixing and breathing patterns, especially the I:E ratio and expiratory flow.

2. Model studies embody nonphysiologic states, particularly lack of responsiveness to carbon dioxide and simplified flow patterns.

3. Studies were done in awake volunteers, whose metabolic rates and physiologic responses differ from those of anesthetized patients.

4. Imprecise endpoints were used, such as rebreathing of carbon dioxide identified by capnography rather than by an increase in alveolar or arterial carbon dioxide concentration.

However, consensus has been reached in one regard: systems classified as Mapleson A (Magill attachment, Lack, and Humphrey A) are most efficient for spontaneous, unassisted ventilation, and those classified as Mapleson D, E, or F (Jackson-Rees, Bain, Humphrey DE) are most efficient for assisted or controlled ventilation.

A general criticism of the published analyses of breathing circuits is a failure to distinguish between the quantity of reinspired carbon dioxide and minimum inspired carbon dioxide tension. The most common tool, a capnograph, displays a signal of airway concentration as a function of time. Thus, if airway carbon dioxide falls slowly with inspiration, just reaching zero near end inspiration, it is interpreted as no rebreathing, even though a significant amount of carbon dioxide has been reinspired. Conversely, if airway carbon dioxide falls to a low but nonzero concentration for all of inspiration, carbon dioxide excretion may be adequate despite perceived rebreathing if total ventilation is increased. Inspired carbon dioxide is properly calculated as the integral of instantaneous flow multiplied by instantaneous carbon dioxide concentration, which is difficult or impossible to measure with simple instrumentation. (See also sections on volumetric capnography in Chapters 8 and 10.) A better analysis is based on the equation of defining alveolar ventilation ( A):

A):

(4-5)

(4-5)

Equation 4-5 states that alveolar ventilation is the quotient of carbon dioxide production and alveolar fractional concentration of carbon dioxide. Because the fractional volume of alveolar carbon dioxide (FACO2) is proportional to the partial pressure of alveolar carbon dioxide (PACO2), a specific PCO2 defines one and only one  A in a given patient. Equation 4-6 demonstrates that any increase in dead space ventilation (VDS × f) can be accommodated by an equivalent increase in minute volume (

A in a given patient. Equation 4-6 demonstrates that any increase in dead space ventilation (VDS × f) can be accommodated by an equivalent increase in minute volume ( E), keeping alveolar ventilation, and hence carbon dioxide elimination, constant. Any amount of carbon dioxide may be rebreathed, at a concentration equal to or below alveolar carbon dioxide, if an increase in minute volume maintains alveolar ventilation.

E), keeping alveolar ventilation, and hence carbon dioxide elimination, constant. Any amount of carbon dioxide may be rebreathed, at a concentration equal to or below alveolar carbon dioxide, if an increase in minute volume maintains alveolar ventilation.

Even if instantaneous PCO2 reaches zero near end inspiration, a significant volume of carbon dioxide may be rebreathed, requiring an appropriate increase in minute volume. A numerical example may help clarify this. Consider a patient in need of 4 L/min of  A with FACO2 of 0.05 (5%) and a current

A with FACO2 of 0.05 (5%) and a current  E of 6 L/min with a respiratory rate (f) of 20 breaths/min. The patient could rebreathe 2.5% carbon dioxide and keep FACO2 at 5% if the apparent alveolar ventilation doubled to 8 L/min. If the dead space ventilation did not change—it probably would, but not much, depending on whether tidal volume or f were increased—a total minute volume of 10 L would suffice. Clearly, an inspired carbon dioxide load can be compensated for. Note that the ventilatory response to carbon dioxide of an awake person (slope of 2 L/min/mm Hg) would require a rise of less than 2 mm Hg PACO2. However, at a sensitivity to carbon dioxide frequently seen in an anesthetized person (e.g., 0.5 L/min/mm Hg), the carbon dioxide tension would have to rise nearly 8 mm Hg. Thus a significant difference is apparent between spontaneous breathing, for which ventilation is set by the patient’s PACO2 and responsiveness, and controlled ventilation, for which minute volume is set by the anesthesiologist.

E of 6 L/min with a respiratory rate (f) of 20 breaths/min. The patient could rebreathe 2.5% carbon dioxide and keep FACO2 at 5% if the apparent alveolar ventilation doubled to 8 L/min. If the dead space ventilation did not change—it probably would, but not much, depending on whether tidal volume or f were increased—a total minute volume of 10 L would suffice. Clearly, an inspired carbon dioxide load can be compensated for. Note that the ventilatory response to carbon dioxide of an awake person (slope of 2 L/min/mm Hg) would require a rise of less than 2 mm Hg PACO2. However, at a sensitivity to carbon dioxide frequently seen in an anesthetized person (e.g., 0.5 L/min/mm Hg), the carbon dioxide tension would have to rise nearly 8 mm Hg. Thus a significant difference is apparent between spontaneous breathing, for which ventilation is set by the patient’s PACO2 and responsiveness, and controlled ventilation, for which minute volume is set by the anesthesiologist.

Any gas mixture that contains carbon dioxide can be considered to consist of a fraction of carbon dioxide–free gas and a fraction of alveolar gas. Any rebreathing of alveolar gas is simply added dead space and can be compensated for by increasing overall ventilation. For example, given 4 L/min of alveolar ventilation and 2 L/min of dead space ventilation, what will happen if a patient suddenly inspires 1% carbon dioxide? Each unit of alveolar ventilation now holds only four-fifths of the previous level of newly produced carbon dioxide, so increasing alveolar ventilation by 125% will result in the same degree of carbon dioxide elimination.

Mapleson A Configurations and Carbon Dioxide Removal

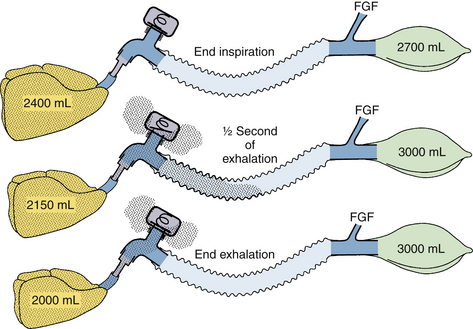

Consider first the Mapleson A circuit shown in Figure 4-15. The assumptions for this model include spontaneous breathing with a rate of 20 breaths/min, tidal volume (VT) of 400 mL, I:E ratio of 1:2, a sinusoidal inspiratory flow averaging 24 L/min, a near exponential expiratory flow with a half-time of less than 0.5 second, a functional residual capacity (FRC) of 2400 mL, a fresh gas flow of 6 L/min, a bag of 3 L nominal volume at the pop-off valve opening pressure, and a corrugated tube of 500 mL volume. The top diagram shows the condition at end inspiration, after the lung has inspired 400 mL over 1 second, consisting of 100 mL of fresh gas flow and 300 mL from the circuit. All of the circuit has been flushed with fresh gas, and carbon dioxide is found only in alveolar gas (stippled area). In the first 0.5 second of exhalation, 250 mL of gas are exhaled and, together with 50 mL of fresh gas, have distended the reservoir bag to 3 L and have just opened the pop-off valve (see Fig. 4-15). Carbon dioxide–containing alveolar gas has penetrated partway down the breathing tube, but the exact distance depends on the dead space; the shape and volume of zones I and II of the capnogram (see Chapter 10 for capnogram zones); and the longitudinal mixing, or conical flow pattern, in the tube. In the next 1.5 seconds of exhalation, the rest of the expired alveolar gas (150 mL) has exited the pop-off valve, and 150 mL of fresh gas has flushed the carbon dioxide–containing expirate in the breathing tube back and out through the pop-off valve. If the sum of the fresh gas flow (150 mL) and the carbon dioxide–free dead space gas from zone I exceeds the penetration of zone II and alveolar gas, the situation at the end of exhalation, as shown in the bottom diagram of Figure 4-15, is the result. This generally is true when fresh gas flow exceeds 55% of the respiratory minute volume.106,107 In this particular model, about 100 mL of fresh gas exits the pop-off valve with each breath along with the carbon dioxide–containing alveolar expirate. In studies of anesthetized patients, the fresh gas flow that maintains carbon dioxide homeostasis in Mapleson A circuits used with spontaneous breathing has been found to be 70% to 100% of the minute volume, depending on the many variables.107-109

FIGURE 4-15 Mapleson A circuit, spontaneous breathing. Stippled areas indicate carbon dioxide–containing gas. Top, The end of a normal spontaneous inspiration for a normal adult patient. As the patient begins to exhale, carbon dioxide–free gas flows from the upper dead space, then carbon dioxide–rich gas flows into the corrugated tube and, together with continuing fresh gas flow (FGF), fills the bag a half second later (middle). The rest of the expirate goes out through the pop-off valve, along with carbon dioxide–containing gas in the tubing, which is pushed toward the pop-off valve by the fresh gas flow. Optimally, at end exhalation (bottom), the circuit has largely been flushed of carbon dioxide.

During assisted or controlled ventilation, two different things happen to decrease efficiency. First, the bag must be squeezed during inspiration, both to deliver the entire tidal volume (400 mL) and to vent the fresh gas flow that comes in over an entire respiratory cycle (in this case,  of 6 L/min, or 300 mL). Now all the exhaled tidal volume flows into the breathing tubing, followed by the continued fresh gas flow during the end-expiratory pause. During the next compression, some alveolar gas may reenter the airway until the circuit pressure rises to the threshold of the pop-off valve. Thereafter, some carbon dioxide and some fresh gas go both to the lung and to the pop-off valve. Understandably, the effect would depend on the rate of compression of the bag, that is, the inspiratory flow, lung and chest wall compliance, airway resistance, volume of dead space, I:E ratio, and fresh gas flow. Thus, during assisted ventilation, the Mapleson A circuit is far less efficient than during spontaneous ventilation in terms of preventing rebreathing.